Injuries related to lifting are often particularly troubling because it can be difficult to treat these types of injuries. Lifting something improperly can cause your back to spasm, which is extremely painful. In some cases, however, there is little that can be done to fix the problem quickly. Doctors often prescribe rest and pain killers, which can cause employees to miss a lot of work.

According to OSHA's page, Materials Handling - Heavy Lifting:

"Lifting heavy items is one of the leading causes of injury in the workplace. In 2001, the Bureau of Labor Statistics reported that over 36 percent of injuries involving missed workdays were the result of shoulder and back injuries."

Preventing Lifting Injuries

The best way to deal with lifting-related injuries is to do everything possible to prevent them. Fortunately, there are many things that can be done to prevent employees from getting hurt. The following are some ways that an employer can reduce the number of accidents that occur in the workplace because of lifting:

- Provide Lifting Gear - When lifting, it is important to protect your back. Using weight belts to provide extra support to the lower back is a great way to help prevent injuries. Another option is to use lifting straps, which provide increased control and support when lifting large or oddly shaped objects.

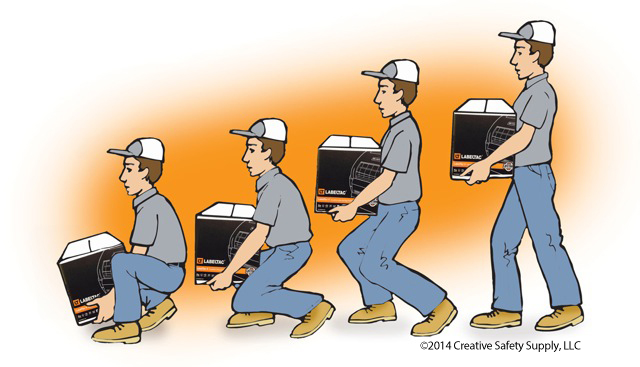

- Proper Lifting Techniques - Training employees about how they should lift to minimize the risk of injury is essential. Employees should know they need to lift with their legs and not their backs. Show a training DVD such as Back Injury Safety to provide tips and lifting techniques to help avoid back injuries.

- Clearly Label the Weight of Items - If something is going to be lifted, it should be clearly marked with how much it weighs so the person lifting it is aware. An industrial label maker can be a great tool to help label weights. Labeling weights can help an employee decide whether to lift it on their own, get help, or even use a dolly or mechanical lifting machine.

- Have Dollies Available - Dollies are an excellent way to move most objects around without putting employees at risk. This is perfect for boxes or many other common items. By putting the loading tray under the items and tilting the dolly back, employees can lift extremely heavy items with minimal risk.

- Have Forklifts Available - Forklifts are an important machine in most facilities. They are required for lifting large or bulky items, but they can be very helpful for other things as well. Having these machines around will allow the employees to make the smart decision to let the machines do the heavy lifting.

- Require Proper Lifting Decisions - Make sure everyone in the facility knows that items over a certain weight require two or more people to lift them, or the use of a dolly or forklift. Even if someone thinks they can lift a heavy item on their own, it is best not to take the chance. Having a policy that requires people to take safety seriously can often prevent a lot of workplace injuries.

Each facility will have to have its own specific set of requirements to protect people from getting hurt while lifting. Having some standard rules, however, will keep everyone much safer and works as an excellent starting point. Most facilities can dramatically reduce the number of injuries that occur from lifting by simply talking about it openly. Letting all employees know that this is a real risk will often cause employees to have a second thought so they don't make unwise decisions.

Responding to a Lifting Injury

While prevention is the best option when it comes to lifting injuries, it isn't going to be possible to entirely eliminate all injuries. This is why it is also important for the facility to know how to respond to an injury when it does occur. Some facilities respond to these types of injuries with the "walk it off" mentality, which is a big mistake. Even though there isn't typically an obvious sign of the injury (such as blood or bruising) it is still important to treat it as the serious injury that it is.

If an employee reports that they hurt their back or any other part of the body while lifting something, make sure they get it checked out by a doctor. Some injuries can be very serious and can cause long-lasting injuries if not treated properly. In most cases, however, the employee will recover fully with just a little rest.

They may be able to work in a less physically intensive job for a few days while their injury heals. If that is not an option, taking a day off is often all it will take to be able to make a complete recovery. If, however, the employee tries to keep pushing themselves even when injured, they will often hurt themselves even worse. This can cause long-term or even permanent injury.

Lifting injuries need to be taken very seriously, and when companies address them properly, the impact can be minimized. Take the time to do everything possible to help employees recover after they've been injured and then help them to prevent this type of injury from occurring again. By working with the employees on injury prevention, most facilities can keep everyone healthy and productive, which is important for the success of any facility.

Resources

Similar Articles

- Catchy Safety Slogans for the Workplace

- Forklift Safety

- Improving Workplace Electrical Safety

- Forklift Safety Procedures

- 15 Forklift Safety Tips [Industry Expert Advice for Safe Operation]

- Addressing Biohazard Safety in the Workplace

- A Guide to Workplace Safety Signs

- Arc Flash and Electrical Safety

- Workplace Safety Inspections & Audits

- Fire Safety in the Workplace