Best Industrial Floor Tapes Chart

| Name | Description | Link |

|---|

| 1. SafetyTac 2.0 |

Most durable floor tape on the market. Great for high-traffic areas. |

Get latest price |

| 2. SafetyTac |

Dependable industrial floor marking tape. Works well in any industry. |

Get latest price |

| 3. Smart Stripe Tape |

Budget-friendly vinyl tape for lighter traffic areas. It also has an ultra-low profile. |

Get latest price |

![SafetyTac Yellow Roll Out]() Remember: Be sure to get a floor marking tape that matches the needs of your facility!

Remember: Be sure to get a floor marking tape that matches the needs of your facility!

Floor paints and light duty tapes, while cheaper, tend to wear much faster in areas with heavy traffic and may need to be replaced at shorter intervals.

On the other hand, heavy duty industrial floor tapes will withstand forklift traffic, heavy foot traffic and even big truck and vehicle traffic, so be sure to keep this in mind if your facility has any of these wear-and-tear hazards.

Functional Properties of Different Floor Tapes

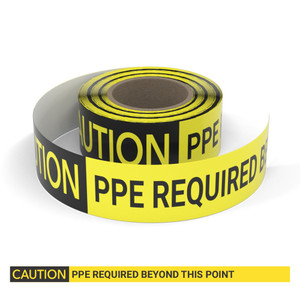

Hazard Tape:

Hazard tape is used when you need a strong visual signal that a danger is near. It is most commonly seen as the black and yellow striped tape on stairs and marking dangerous areas. This marking tape is also available in these color combinations: red and white, green and white, and black and white.

Reflective Tape:

Reflective safety tape has the ability to redirect, or reflect, light when it hits the tape. It is effectively utilized in both low light and dark areas. Safety tape with a reflective surface is produced from metals, prisms, and glass. This type of warehouse floor tape is used to improve the visibility of the floor markings. It can be used in aisles, on poles, in walkways, in loading docks, on protruding objects, in storage zones, and in other areas.

Non-Skid Tape:

Non-skid tape is ideal in areas where you are trying to eliminate slip and fall accidents. This no slip tape is commonly referred to as non-skid, anti-skid, anti-slip, and traction tape. Anti-skid industrial floor tape is an industrial strength tape that can withstand extreme work environments. For some situations, such as stairs, yellow and black striped traction tape may be your best choice. Specialty anti-slip tapes include: yellow tape with “Caution Watch Your Step” written on it, glow-in-the-dark traction tape, mop friendly tape, high visibility traction tape, studded anti-slip tape, and barefoot anti-slip tape. Barefoot anti-slip tapes are mainly used in showers, offices, locker rooms, and baths. Studded anti slip tapes can be utilized in extremely dry or wet, or extremely hot or cold climates. This studded traction tape is good in environments with high cart and foot traffic. It is also utilized in transportation. If the area has very high moisture or is constantly wet, verify that the adhesive will withstand the moisture requirements.

Vinyl Floor Tape:

Vinyl tape can be utilized to mark equipment, tools, aisles, and floors in warehouses, manufacturing environments, offices, classrooms, gyms, and other places.

Industrial Tape:

Industrial strength floor tapes are commonly used in environments with heavy foot and vehicle traffic and in places where the tape will be exposed to different chemicals and water. Industrial strength safety tape from SafetyTac® is strengthened with an adhesive that is rubber-based.

Glow in the Dark:

Glow-in-the-dark floor striping tape is chosen for situations where there would be safety issues if the lights suddenly went out. It is also known as photoluminescent tape. Glow tape is vinyl tape that has been treated with phosphor. Phosphor has the ability to radiate visible light after it has been energized, or charged. Phosphor absorbs radiation from the light. The phosphor then releases the light radiation back out into the environment, which is then visible to the human eye. Some glow-in-the-dark tape charges in less than 30 minutes and will glow for 2-3 hours after the lights have gone out. There are specialty glow-in-the-dark floor markings such as: traction tape that glows in the dark, striped glow-in-the-dark tape, glow-in-the-dark arrows, and specialty floor signs that glow in the dark. Specialty floor graphics say things like “Emergency Exit,” “Yield,” “Evacuation Route,” “Exit this Way,” and “Caution, Watch Your Step.”

Carpet Tape:

Carpet tape comes in many colors and is used for marking floors in offices, classrooms, and other carpeted areas. Carpet safety tape is specially designed so that it doesn’t leave behind excess adhesive upon its removal.

Floor Tape for Classrooms and Gyms:

Classroom and gym floors can utilize the same kind of floor marking tapes to make lines. A tape should be used that can withstand heavy pedestrian traffic, is curl resistant, is tear resistant, and is stretch resistant. This tape should be able to withstand chemicals and water exposure. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=DIRECTIVES&p_id=1758

Colors

Floor marking tapes come in many colors. These colors include fluorescent neon yellow, glow in the dark, red, orange, purple, yellow, green, blue, white, silver, grey, brown, green and white striped, red and white striped, yellow and black striped, as well as black and white striped.

Durability

It is important that the tape can survive repeated forklift abuse if forklifts are used in your facility. Floor tapes can come in regular strength and industrial strength. The thicknesses of a particular tape can affect its durability.

Thickness

Floor tape thickness can vary. Some floor safety tapes range from 2 mil to 50 mil. Mil is a measurement used for thickness. 1 mil is equal to .001 inch. If the floor marking tapes installed are too thick, feet and brooms can catch on them. If it is too thin, its durability can be compromised.

Application

Floor tape is available with applicators to make it easier to apply. There are also industrial tape and vinyl tape rolling applicators. These applicators hold rolls of floor marking tape. They have wheels and an upright handle, similar to a vacuum, and as you roll the applicator forward the tape is dispensed onto the floor.

Floor Paint VS Floor Tape

Floor paint has the problem of wearing off overtime, being messy to apply, and being difficult to remove. When using floor tape you do not have to wait for it to dry, it comes with different durability options, and it can be easily removed if you change the organization of your facility.

Floor Tape Corners and Shapes

Adhesive floor markings also come in corners and other shapes to increase your possible options for organization. Some available shapes are corners, arrows, circles, dots, footprints, triangles, T’s, X’s, and L’s.

Custom Floor Marking Signs

Custom floor decals can either be designed and printed for you or printed yourself. You can make your custom floor markings with an industrial label printer that is specifically designed for this purpose. Make sure the sign and label designs you use are bold and eye-catching. http://cdn.thomasnet.com/ccp/30155299/49725.pdf

Why is Floor Marking Important?

Marking tape, floor signs, floor labels, and floor shapes help make a facility a visual workplace. In a visual workplace things are done more safely and efficiently because people can easily follow signs instead of needing to stop and ask questions. Floor markings can designate aisles and pedestrian walkways, mark hazards, and indicate where certain items should be placed. These lines of demarcation divide space so it can be more organized, safer, and utilized more efficiently.

Floor Marking for OSHA Compliance

OSHA’s standard for Walking-Working Surfaces (29 CFR 1910.22) references the need for floor markings in the workplace. The standard emphasizes the importance of marking aisles and pathways and keeping them clear. In a letter of interpretation about the standard, OSHA explains in more detail how the need to maintain clear walkways relates to floor safety markings.

First, OSHA states that lines must be used to delineate aisles. These lines can be made from floor marking tapes or shapes such as dots or strips. Any color lines are acceptable as long as they clearly mark the aisle.

Then OSHA addresses the size of the markings themselves as well as the size of aisles. Floor lines should be at least two inches wide. Wider widths are also acceptable. Aisles themselves need to have adequate space for people and workplace vehicles to pass through them safely. If equipment will be used in an aisle, the aisle should be at least three feet wider than that equipment. At a minimum, all aisles should be at least four feet wide.

These are OSHA’s only explicit requirements for floor markings, but businesses can also use them to increase employee safety in other ways. For example, a safety manager could place tape around hazardous areas such as electrical panels or machines with moving parts to warn people of danger. These markings work well in conjunction with other safety signs and labels. http://www.slideshare.net/bengeck/guide-floor-marking

5S & Floor Marking

5S, the Lean manufacturing practice that aims to keep the workplace organized, clean, safe, and efficient, benefits from the use of floor markings, too. 5S—which stands for Sort, Set in Order, Shine, Standardize, and Sustain—relies heavily on the use of visuals to communicate basic information about organizing and maintaining the workspace. A particular color of marking tape, for example, could indicate a space is used for a particular activity. Shapes like corners or T’s could be used to outline where a piece of equipment belongs so it always ends up in the same place. Signs and labels could provide further instructions.

These visual cues are simple, but they reduce the need for people to ask questions. They also prevent items from getting misplaced and potentially damaged. Both of these things help increase an organization’s overall efficiency.

Aisle Marking

Aisle Marking Marking Pallet Locations

Marking Pallet Locations Lean Manufacturing

Lean Manufacturing Forklift Safety

Forklift Safety Safety

Safety 5S/Lean

5S/Lean Organization

Organization Hazards

Hazards Crosswalks

Crosswalks Work Cells

Work Cells

Remember: Be sure to get a floor marking tape that matches the needs of your facility!

Remember: Be sure to get a floor marking tape that matches the needs of your facility!