-

Overview Low Profile SafetyTac®'s low profile allows it to sit smoothly on your floors, so it will not create a tripping hazard. The Toughest Floor Tape on the Planet SafetyTac® can withstand the tough conditions of an industrial... More details

-

Overview Ultra-Low Profile Smart Stripe Tape sits smoothly on floors and won’t snag or cause tripping. Easy to Install Just peel off the backing and stick the tape to a clean, dry surface. Resistant to Traffic This tape can hold... More details

-

Overview Ultra Lean. Ultra Tough. Made with the same durable material as standard SafetyTac®, but it has an ultra-low profile that's 40% thinner than most other industrial floor marking tapes. Industrial Strength SafetyTac® LEAN can... More details

-

Overview Ultra-Low Profile Smart Stripe Tape sits smoothly on floors and won’t snag or cause tripping. Easy to Install Just peel off the backing and stick the tape to a clean, dry surface. Resistant to Traffic This tape can hold... More details

-

Smart Stripe Removable Carpet Floor Marking Tape Smart Stripe Carpet Tape is a floor marking tape specially designed to stick on carpet. The adhesive won’t leave a residue after it’s removed, even when the tape been on the carpet for an... More details

-

Gauge Warning Film Circles These pre-cut circles come in a range of diameters to fit most gauge faces. With these circles, you can mark any gauge to help keep machinery within a range. Simply cut the full 360° circle to... More details

Gauge Warning Film Circles

$12.00 -

DOT-C2 Reflective Tape for Vehicle Marking Reflective floor tape can stop accidents before they happen and help ensure employee safety. Conspicuity DOT-C2 Tape is designed for use on trucks and trailers and exceeds NHTSA standards for vehicle... More details

-

-

Warning: Pinch Point Keep Hands And Feet Clear - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

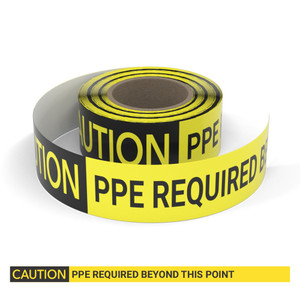

Caution: PPE Required Beyond This Point - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Do Not Cross This Line - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

PPE Required Beyond This Point - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Caution: Tripping Hazard - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Caution: Electrical Panel Must Be Kept Clear - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

FOD Critical Area - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Caution: Keep Clear At All Times - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Caution: Non-Potable Water Do Not Drink - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

FOD Awareness Area - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Fire Extinguisher - Do Not Block - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Notice: GMP Area PPE Required - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Caution: Forklift Traffic - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Electrical Panel - Do Not Block - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

No Forklifts - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to necessary... More details

-

Warning: Low Clearance - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Caution: Not A Step - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

3" x 1000' per roll Multiple options available Non-adhesive Printed Barricade Tapes are a quick and effective way to create a visual perimeter around temporary hazards. These rolls are 1000' in length so even the largest hazards can be surrounded... More details

Printed Barricade Tape

$36.00 -

Warning: Pinch Point Hazard Keep Hands Clear - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

Notice: Gmp Area Ahead - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Warning: Storage Not Permitted Past This Line - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

Notice: Safety Glasses Required Beyond This Point - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or... More details

-

Caution: Do Not Cross This Line - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Caution: Do Not Step Here - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

FOD Control Area - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Notice: Avoid A Fall - Use Handrails - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct... More details

-

Do Not Enter / No Entre (Bilingual Spanish) - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

Authorized Personnel Only Beyond This Point - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

Caution: Watch Your Step - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Quality Control - Hold - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to... More details

-

Caution: Keep This Area Clear At All Times - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully... More details

-

Restricted Area - Smart Stripe Inline Printed Floor Tape Printed on durable Smart Stripe Tape, our inline printed floor tape features important messaging designed to call attention to potential nearby hazards or helpfully direct pedestrians to necessary... More details

Safety Tape

Heavy duty vinyl tape for marking

floors and hazardous areas.

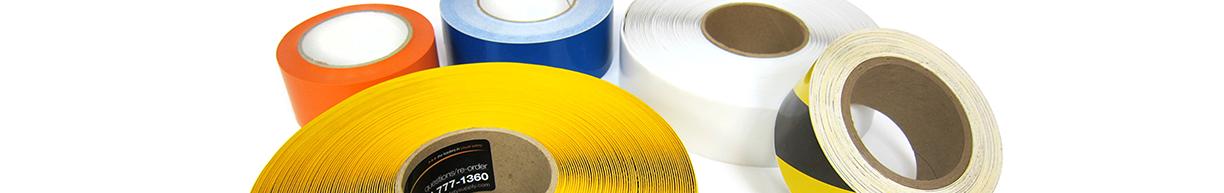

Safety tapes serve important functions in the workplace. They highlight hazards, mark walkways and aisles, help people find egress routes, and add traction. These safety tapes provide visual cues or instructions that make it easier for people to navigate through spaces, and in some cases they even improve the walking surface.

A variety of safety tapes are available, and they have varying levels of visibility and durability. They also come in many colors, patterns, and widths. SafetyTac® floor marking tape is a popular tape for industrial facilities or warehouses because of its strong material and ability to withstand high levels of foot and vehicle traffic. SafetyTac® Lean works well in high-traffic areas where you need tape to have an ultra-low profile, and Smart Stripe Tape is ideal when you need an economical solution for areas with lower traffic levels. Browse all of our safety tapes below, and get in touch if you’re interested in a free sample pack.

Free Floor Marking E-Book

Get our popular Floor Marking Guide e-book and Floor Marking Poster.

(Poster by mail. US/Canada only)

Not sure which floor tape you need?

Use the floor tape finder to help you make the right choice for your application.

Helpful Resources