- What is an Aisle?

- Line Marking Tape

- Strong Tape #1 - SafetyTac® 2.0 with Armor Technology

- Aisle Markers

- Colored Aisle Markings

- Strong Tape #2 - Tape Protection

- Aisle Marking Paint

- Aisle Painting

- Forklift Aisles

- Strong Tape #3 - Floor Signs

- Aisle Signs

- Strong Tape #4 - Vinyl Floor Tape

- Aisle Marking Tape Video

- Aisle Tape Applicator

- Practicing in Small Areas

- Strong Tape #5 - Durastripe Tape

- Aisle Runner Tape

- Aisle Walkway

- Aisle Define

- Aisle Number Signs

- Using Aisle Marking Tape to Meet Standards & Regulations

- Standard Aisle Width in Warehouses

- Aisle Width for Forklifts

- Minimum Aisle Width for Forklift

- Forklift Aisle Width Standards

- OSHA Aisle Width Requirements

- OSHA Minimum Aisle Width

- Aisle Marking Tape Training

- Heavy Duty Floor Marking Tape

When using aisle marking tape in your facility, one of the most important things to consider is the strength of the tape. This is because the tape needs to stand up to some very difficult conditions. People will be walking on it, but there will also be indoor vehicles driving over it and carts being pushed over it. To make matters worse, some of the vehicles, such as forklifts, will be dragging hard metal objects or wooden pallets over the tape.

When using aisle marking tape in your facility, one of the most important things to consider is the strength of the tape. This is because the tape needs to stand up to some very difficult conditions. People will be walking on it, but there will also be indoor vehicles driving over it and carts being pushed over it. To make matters worse, some of the vehicles, such as forklifts, will be dragging hard metal objects or wooden pallets over the tape.

If you don't use the strongest tape available, you will quickly find the tape peels up in some areas. Once the tape begins to peel, it won't take long for it to become so damaged that it is no longer useful, or worse, it causes a tripping hazard.

Take some time to learn as much as you can about the strongest aisle marking tapes and how they can be used in almost any facility. The more you learn about these tapes, the better decisions you can make for your company.

Before looking at specific types of tape, however, take a moment to understand what an aisle is and why it requires such strong tape.

What is an Aisle?

The dictionary defines aisle as "a walkway between or along sections " or "a longitudinal division of an interior area". This is a pretty basic definition, but it does get the point across. To be an aisle, an area typically needs to be much longer than it is wide and in most cases, there are multiple aisles in an area.

The dictionary defines aisle as "a walkway between or along sections " or "a longitudinal division of an interior area". This is a pretty basic definition, but it does get the point across. To be an aisle, an area typically needs to be much longer than it is wide and in most cases, there are multiple aisles in an area.

One of the most common examples of an aisle is in a warehouse. Warehouses typically have large shelving units, which are separated by aisles. This arrangement allows employees to easily access every set of shelving without trouble.

Let's also take a look at some other examples of where we may see aisles, as well as areas that share the characteristics of aisles and may benefit from aisle marking tape:

- Supermarket Aisles - Supermarkets are a very common place to find aisles and they get a lot of frequent traffic. In addition to the obvious foot and cart traffic, however, remember that there are also pallets, forklifts, and other heavy items going through to keep the shelves stocked.

- Hospital Hallways - Hospitals typically have many long hallways, which are effectively just aisles. These hallways often need to have markings on them to ensure everyone knows how to travel safely. They also have lots of traffic and sometimes heavy equipment so having strong aisle marking tape is essential.

- Manufacturing Facilities - Manufacturing facilities usually have traditional aisles as well as hallways, both of which will require some type of markings to keep everyone safe.

- Construction Sites - While at a construction site, you may notice some halls or aisles are marked to ensure people know where they need to go and what other things they can expect to see in the area.

These are just a few of the many places that you can expect to see an aisle. While aisles can be very different from location to location, they will all require some type of aisle marking tape to ensure everyone stays safe and can work efficiently.

Line Marking Tape

One last point to cover before getting into some examples of durable aisle marking tape. The vast majority of floor markings are simple line marking tape. Projects involving this tape often require significant amounts of tape. This is because most aisles are quite long and will require at least two strips that cover the full length.

Just because line marking tape is significantly more popular, however, doesn't necessarily mean it is more important. Taking the time to learn about both long and straight markings and those that are other shapes will help you to get the best results for your facility.

Floor markings such as floor marking tape are an important part of visual communications within most facilities. Learning about these items and how they can improve the safety, efficiency, and overall quality of a facility will provide you with many benefits in both the short and long term.

Strong Tape #1 - SafetyTac® 2.0 with Armor Technology

The first type of aisle marking tape to consider is from SafetyTac®. It is called SafetyTac® 2.0 with Armor Technology and is built to stand up to the most difficult environments. This type of tape can come in a wide range of colors, which makes it ideal for marking aisles and other places where different colors can have different meanings.

It also comes in different widths and lengths, which can be very helpful for ensuring you get the best results based on your needs. This tape is made with specific specs to help make it as durable as possible. Take a look at some of these features:

- Low Profile - This tape maintains a very low profile. This means it won't be a tripping hazard. It will also contribute to ensuring everything goes up and over it rather than through it.

- Easy Glide - The tape is made to allow shoes and tires to pivot on top of it without pulling the tape up off the ground. Even a fully loaded high-low or forklift can turn its tires on this strong tape without damaging it.

- Shatter Resistant - This tape won't shatter or break, even with hard or heavy objects dropped directly on it. This is important because even small cracks can quickly lead to further damage when using aisle marking tape.

Whether you're choosing this aisle marking tape just to mark aisle boundaries or as a visual communication tool as well, you will love how durable it is. Let's take a look at some of the many ways this tape can be used to see why it is an excellent option for almost any environment.

Aisle Markers

One of the most popular ways to use this tape is to mark off aisles. This could mean defining the aisle width or marking a feature of the aisle. The tape can be placed either along the edges of the aisle so pedestrians and drivers can see how close to the edge they are or it can be placed at the ends of the aisle.

In both cases you will want to make sure you are using a very durable tape since these environments can often be very tough on floor marking tape. Investing in the more durable options today will help you avoid the costs of having to quickly replace the tape or repair it if it becomes damaged.

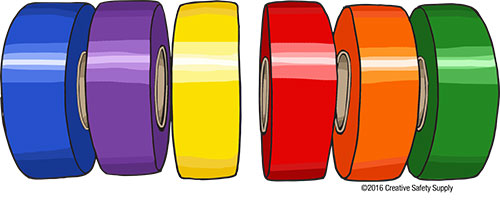

Colored Aisle Markings

Using different colors to indicate different things within a facility is very common. For example, some warehouses will use red aisle marking tape to identify aisles where potentially hazardous materials are stored. Then they can use yellow tape to indicate that the items in a row are not hazardous.

This is a very simple form of visual communication that can have immediate and long-lasting benefits for your facility. The important thing to remember when using aisle markings for visual communication is to ensure the standards are followed throughout the facility.

Strong Tape #2 - Tape Protection

This second example of strong floor marking tape is actually a product that is used to add protection and durability to other floor markings. This is a clear tape that goes over other floor markings to help them avoid damage and last much longer.

You can put this tape on top of aisle marking paint or aisle marking tapes to dramatically extend their life. This means you won't need to replace the markings as frequently.

This tape is easy to install and made to resist abrasions and tears from forklifts or other traffic in the area. It is also resistant to things like chemicals and cleaning products, which is very important in many facilities. Since this tape protection is clear, it won't impact any colored markings that you have either.

Consider some of the following times when using a clear tape protection will be helpful in your facility.

Aisle Marking Paint

If you are using aisle marking paint anywhere in your facility, you will likely find that it will chip pretty quickly when vehicles drive over it. These chips will spread and over time you'll find that the aisle marking paint is no longer easy to see, especially from a distance.

When you use this tape protection product on top of the aisle marking paint, however, it will provide an excellent layer of protection to help you avoid problems. This can be used in many situations throughout the facility. If you have marked the edges of an aisle with paint, for example, you can put this type of protection down over it as soon as the paint has dried.

Aisle Painting

In addition to marking the edges of an aisle using paint, some facilities paint symbols or aisle number signs on the floor. Putting the protection tape down over these types of aisle paintings will protect them from damage so they're easy to see for much longer than would otherwise be possible.

Of course, whenever possible it is best to use floor marking tape rather than floor marking paint. There are many significant advantages to the tape compared to the paint, which we won't get into here. In many cases, however, people have already used the paint so doing all you can to get the most out of it is always a good idea.

Forklift Aisles

If you have aisles where forklifts constantly drive, it is a good idea to use this type of tape to protect the markings. This applies whether you are using paint or floor marking tape. Forklifts typically cause the most damage to floor markings, so when you know they are going to be used in an area, make sure to protect the markings.

In fact, many companies will include this type of protective tape in their list of forklift aisle requirements. Whether you go that far or not, having a strong floor marking protection tape on hand will be very beneficial to your facility.

Strong Tape #3 - Floor Signs

While most people don't think of floor signs as a type of floor marking tape, they often can be. These floor signs are usually installed using a peel-and-stick system that functions just like tape. While they don't look like tape, they functionally are the same thing.

Since floor signs are much larger than normal aisle marking tape, they can often be damaged more easily, which is why it is so important to choose durable options. A good floor sign should have a strong adhesive that covers the back of the sign so that it will stick securely to the flooring material. In addition, the sign should be made with vinyl or other strong materials that won't be damaged when walked on, run over or otherwise exposed to something that could cause it to be scraped up.

Aisle Signs

Some floor marking signs are made specifically for visual communications on or around aisles. The following are a few common types of aisle signs that you may see:

- Aisle Number Signs - Numbering aisles is very common and can help improve organization and efficiency within the facility. Using floor signs as aisle number signs is an effective practice.

- Safety Signs - Using floor signs as visual communication tools to let people know of potential risks in a particular aisle is very helpful.

- Directional Signs - Using a sign in an aisle to give people directions can be useful. For example, you could use a sign that directs people toward specific items in stock.

- Size Information - Forklift and other vehicle drivers need to know that an aisle is wide enough for them to safely drive through it. Using a floor sign to mark OSHA aisle width, for example, can be helpful. In pedestrian areas you can also mark the OSHA walkway width so people can see it.

Strong Tape #4 - Vinyl Floor Tape

Vinyl floor tape is one of the most common options used in many facilities and it is very strong. The vinyl material is strong enough to stand up to almost any environment. It is also usually made to be waterproof, chemical proof and friction proof so that it can last for a very long time even near doorways or loading docks where it may be exposed to the elements.

Vinyl floor tape can come in many different forms. Most commonly it is long and fairly narrow, which makes it perfect for marking off areas in a facility. It can also come in shapes, pictograms and much more. No matter what information you would like to convey on the floor of your facility, you will find there is vinyl floor tape designed to meet those needs.

Learning how to install vinyl floor tape or any other type of floor marking tape is very important. While it isn't difficult, there are some things you can do to make sure the installation process goes smoothly. Consider the following options for learning about installing aisle marking tape in your facility.

Aisle Marking Tape Video

There are many aisle marking tape videos published on the internet that can provide tips and tricks for how to properly install this type of tape. These videos provide a lot of great information to help you put your tape down properly so that it will be straight, even and stuck firmly to the floor.

You can see an excellent example of an aisle marking tape video here:

As you watch this video you will quickly notice that there are many other videos out there. Some of them will help explain how to put aisle marking tape down, others will show how to install floor marking signs. Looking for the right video based on the exact tasks you need to complete is fast and easy. You can find everything you need so that you can get your job done properly without any issues.

Aisle Tape Applicator

Aisle tape applicators are another excellent option for applying tape the floors of your facility. There are many types of applicators on the market to choose from. They work differently based on the type of marking tape you are using. Most of the top aisle tape applicators, however, will be able to put down almost any type of vinyl floor markings you may have.

These applicators are especially nice because they help your aisle markings go down evenly. When working with floor marking tape of any kind you should avoid any creases in the tape since this could lead to weak points that could get damaged over time. By using an aisle tape applicator, you can be much more confident that the tape will be applied firmly and smoothly.

On the opposite end of the spectrum, there are also aisle tape remover devices that can be very useful. These are important because tape is designed specifically to stay in place even through harsh conditions, so removing it can be challenging. Having a remover tool will help you get the tape up much more quickly than you could using just your hands or even other tools commonly found in most facilities. While it is best to not remove aisle marking tape, sometimes you'll find it is necessary, and when that is the case, having a remover is important.

Practicing in Small Areas

When it comes to learning how to put aisle marking tape down properly, there is nothing better than getting experience. Fortunately, even heavy-duty floor marking tape is quite affordable, so it is worth it to practice putting the tape down in small areas.

Some people choose to put the tape down in a spot that won't get much traffic so even if there are minor imperfections they can be left there without causing issues. Others choose an area to practice where they can put the tape down and then pull it back up if they make mistakes.

Whatever you choose to do, make sure you know it is acceptable to practice putting the aisle marking tape down until you get the hang of it.

Strong Tape #5 - Durastripe Tape

Durastripe is a line of durable floor marking tape and other floor marking items. In addition, there are different levels within this type of tape so you can get the level of strength and durability you need. The Durastripe X-Treme line, for example, is made to stand up to very heavy traffic without a problem.

No matter what type of aisle markings you require, you'll be able to find a wide range of options that use the Durastripe strength. This is very nice because you can use the same type of tape for all your markings, if you prefer. This way you don't need to worry about whether you are using a strong enough tape since all the options in this category are very strong.

Aisle Runner Tape

Aisle runner tape is very common and is usually a very long strip of tape that is put down to mark off the edges of an aisle or walkway. When using the Durastripe tape, you can get aisle runner tape that is a solid color, striped, has words on it, or just about anything else. This can be beneficial to your facility since you can use the different options to convey different messages.

Aisle runners can provide an easy-to-see line that people can follow to so they know where they are supposed to be. One excellent example of how this can be helpful is when looking at forklift drivers. These drivers can line up their tires with the aisle runner tape and as long as they stay in line with the tape they know they are going down a straight path.

They will still need to watch out for pedestrians and other vehicles, but by making sure they are going straight through the aisle they can avoid many types of accidents or mistakes while driving. This is especially popular for newer drivers.

Aisle Walkway

Identifying an aisle walkway is important for the safety of a facility. This is often done by putting down aisle marking tape along the edge in a specific color or design. Once done, train everyone in the facility so they are aware that vehicles are not permitted to go over the line. This will help ensure vehicle drivers can avoid pedestrians and that pedestrians will know where they should remain to avoid danger.

One other important thing to remember about walkways in warehouses and other facilities is that they may have some regulations associated with them. For example, there are a variety of OSHA walkway requirements that need to be followed for compliance.

If you are putting a walkway in your facility, make sure you read through the OSHA walkway width requirements so you don't run into any compliance issues down the road.

Aisle Define

To define an aisle many facilities will use this type of tape. This tape can simply be used to mark the width of the aisles, or you can expand it to mark the long edges as well. This will effectively create a rectangle using aisle marking tape so that people know when they are officially in an aisle and when they aren't. While this may not seem important, it can be for things like assigning work areas and improving safety.

For the area in questions to qualify as an aisle, you will need to meet the requirements of organizations like OSHA. OSHA standards include minimum aisle widths that you must meet for a space to be an actual aisle. If your aisles are not as wide as required, then you will likely not be able to use them as aisles.

In addition to knowing the definition of an aisle yourself, make sure employees are aware of it too. Understanding the types of aisles and spaces in your facility can be very important for safety and making sure everyone stays in the areas where they belong.

Aisle Number Signs

Since this type of tape comes in many shapes, sizes, and symbols, it is no surprise that it can come in numbers. Whether your facility has two aisles or 200, it is a good idea to use aisle number signs so everyone knows where they need to go.

Numbering aisles is an excellent way to improve efficiency and organization. Using floor markings to do this is an affordable and easy to way to accomplish your goals. These are also nice because you can put these tape numbers down in just moments and they will provide valuable information to people throughout the facility for years to come.

Using Aisle Marking Tape to Meet Standards & Regulations

Now that you are very familiar with some of the strongest and most durable floor marking options available, it is a good idea to learn more about how these markings can benefit the facility.

While the list of advantages for using aisle marking tape in your facility is extensive, few of them are more important than helping you stay compliant. There are many standards and regulations that companies of all types have to follow, and in many cases floor markings can help accomplish that goal.

Depending on what type of industry you are in, you may need to follow regulations from OSHA, ANSI, IEEE, and others. Many people who own or manage businesses find that these regulatory requirements are difficult to keep up with. This can certainly be true, but when you take the time to meet the requirements using floor markings as often as possible, you will find that it isn't as difficult as you might have thought.

Consider some of the following requirements that may apply to your facility.

Standard Aisle Width in Warehouses

Before getting into specific requirements for different situations, it is a good idea to learn about the standard aisle width in warehouses. For most situations, an aisle must be at least 48 inches wide. This is not really that wide, and most facilities will have aisles that are wider than this. Having this as a starting point, however, can be very helpful.

Aisle Width for Forklifts

If you want to use a forklift in an aisleway, then you need to make sure it meets the width requirements. OSHA has a list of marking and width requirements for aisles that you need to be aware of and follow at all times.

Once you are familiar with OSHA aisle requirements, you can use floor marking tape to identify the boundaries. Then everyone will know they need to keep the aisle clear of any permanent structures so that your facility remains in compliance with the regulations governing aisle width for forklifts.

Minimum Aisle Width for Forklift

In addition to looking at the requirements from OSHA and other agencies, consider how difficult it will be for your forklift operators to do their job in your aisles. In many cases, you will find it will benefit your facility to have a slightly wider aisle even though you may be able to fit fewer total aisles.

This is because your forklift drivers will be able to operate much more easily and efficiently. This can save a lot of time and effort. Having more room will also make it safer to get the job done without putting people at risk of getting crushed, run over, or have other issues.

To see an example of how much effort it takes to maneuver through very narrow aisles, watch this video. It shows just how much work is involved (and wasted time) operating in these environments:

Forklift Aisle Width Standards

The specific standards in place may vary from industry to industry. For example, most supermarkets don't really need to worry about meeting the requirements from any regulatory agency because they will naturally have their aisles quite wide to meet the needs of their customers.

On the other hand, some warehouses will need to have wider-than-normal widths for their aisles because the warehouse contains hazardous chemicals. When this is the case, some companies implement their own standards to keep the facility, their products, and their employees as safe as possible.

OSHA Aisle Width Requirements

Even if you are not using a forklift in an area, you will need to make sure your aisles are the proper width. This helps keep employees safe while working within the aisles. In addition to being required by OSHA, you will find this is just a good idea since it is difficult to work in a narrow aisleway where you can't move around freely.

OSHA Minimum Aisle Width

OSHA requirements can vary for similar areas, so it is important to keep this in mind. A normal aisle, for example, can be one width, but if you are marking the aisle width for an exit lane it will need to be wider. An exit lane is very important since people need to be able to escape during an emergency. In addition, exit aisles are typically going to be busier than normal aisles, so it makes sense to make them at least slightly wider.

There are many different OSHA minimum aisle width requirements to consider, so make sure to get it right the first time. The OSHA walkway requirements are different than those required for vehicles, so consider this too.

Aisle Marking Tape Training

Whenever implementing anything new in your facility, make sure you provide your employees with the proper level of training. Aisle markings are no exception. Whether you're just marking the edges of your aisles or you're incorporating floor markings into your overall visual communication strategy, it is an excellent idea to formalize the training process.

Teach employees things like what the different colors of your floor marking tape mean. Keeping it all as simple as possible will help everyone learn quickly and benefit from the training.

In addition, work with the maintenance team so they know they can wash the floor marking tape just like any other part of the flooring. Many people mistakenly think they can't wash floor marking tape or marking signs, but the truth is that a clean sign or clean tape will likely last longer than those that are neglected.

When adding aisle marking tape or any other floor markings to your facility, make sure you set up the process for how often it will be cleaned and with what products.

Heavy Duty Floor Marking Tape

Now that you have taken the time to learn all about heavy-duty floor marking tape, you should be prepared to make the best possible decisions for your facility and its aisles.

While floor markings may seem like a small part of overall workplace safety or efficiency planning, it is worth the effort to really think each decision through. When done properly, floor markings can have a dramatic effect on the way your facility operates. On the other hand, facilities that don't put much thought into this topic at all will end up having to redo their work multiple times, which can be costly and wasteful.

One of the main points of using aisle marking tape and other floor markings is to improve efficiency and eliminate waste. This is one of the reasons why these types of markings are so popular in methodologies like lean, six sigma, and 5S. Taking the time to make sure you implement them properly will help you get the most out of all your floor markings.

Before you make any final decisions regarding your facility's floor markings, make sure to refer back to this document and ask yourself if you are choosing markings that will convey the right message and be strong enough to last as long as possible.

Similar Articles

- Types of Floor Marking

- Floor Marking for Factories

- OSHA Floor Marking

- Floor Marking for Fire Extinguishers

- Floor marking comprehensive research, education and training

- Floor Marking Ideas for Warehouses

- Floor Marking for Forklift Traffic

- Floor Marking for Facility Safety

- Forklift Safety

- Floor Stickers – Your floors come alive and speak