- What is a Hazard and Operability (HAZOP) Study?

- Types Of HAZOP

- The Hazard And Operability (HAZOP) Study Process

- Why use HAZOP?

- Advantages and Disadvantages of HAZOP

- Examples of HAZOP Applications:

- Does OSHA Mandate A Hazard Assessment?

- Difference Between HAZOP And PHA

- Difference Between HAZOP and Risk Assessment

- How To Create A HAZOP Study?

- Design A Safety Strategy Using HAZOP With Creative Safety Supply

What is a Hazard and Operability (HAZOP) Study?

HAZOP stands for “ Hazard and Operability Analysis,” and it is a systematic, structured method used to identify problems and address insufficiencies in an existing process or operation. The purpose of this technique is to refine existing procedures, address potential risks, and ensure safe and efficient operations. Being a safety tool, HAZOP is used across various industries like chemical facilities, pharmaceutical companies, oil and gas processing, and nuclear power generation.

Types Of HAZOP

The four types of HAZOP studies are:

Process HAZOP: One of the most commonly used types of HAZOP study. Process HAZOP focuses on exposing the deficiencies and issues that hinder standard procedures found in power and plant systems.

Procedure HAZOP: A more comprehensive approach to risk assessment, Procedure HAZOP focuses on procedures and operational sequences to identify hazards at each point of the streamline or plan of action.

Human HAZOP: Human HAZOP consists of identifying hazards or risks that are a by-product of human errors. It involves evaluating physical or mental erros like, wrong decisions or lack of information which led to exposure of hazard.

Software HAZOP: This HAZOP identifies potential errors or defects (“bugs”) in the development and implementation of software systems. Commonly used in cybersecurity sectors that design security software for banking sectors.

The Hazard And Operability (HAZOP) Study Process

HAZOP study requires a multidisciplinary team that conducts the systematic analysis of a system or process in four different phases, including:

Definition Phase:

The definition phase of HAZOP analysis typically begins with the identification of members for a multi-disciplinary risk assessment team. The risk assessment team should identify the HAZOP study scope to focus efforts in the right direction and clearly define their responsibilities throughout the analysis. The scope of the risk assessment project should include study boundaries, key interfaces, and assumptions.

Preparation Phase:

This phase involves identifying and locating supporting data and information to plan the study. The HAZOF team needs to prepare the schedule, timelines, and template format for recording the Hazard and Operability analysis outputs.

Examination Phase:

The examination phase begins with breaking down the process or complex system under study into small steps or parts. The team should use HAZOP guide words to identify potential areas of deviation from the intent and identify the consequences and causes of problems. Moreover, the significance of each problem should be analyzed along with identification and mitigation mechanisms for each issue.

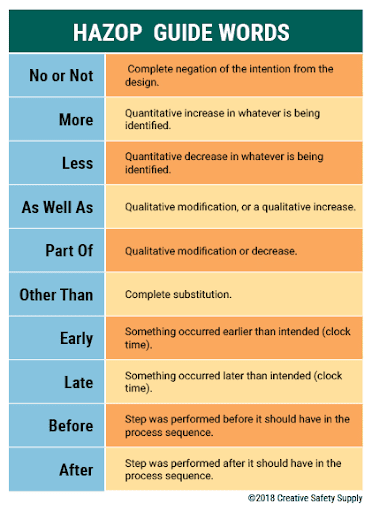

Each guide word has a set meaning when applied to different nodes or variations of the plan. The following is a common set of guide words used in many industries:

No or Not: The complete negation of the intention from the design

More: There is a quantitative increase in whatever is being identified

Less: There is a quantitative decrease in whatever is being identified

As Well As: There is a qualitative modification or a qualitative increase

Part Of: There is a qualitative modification or decrease

Other Than: There was a complete substitution

Early: Something occurred earlier than intended (clock time)

Late: Something occurred later than intended (clock time)

Before: A step was performed before it should have been in the process sequence

After: A step was performed after it should have been in the process sequence

Documentation and Follow-up Phase

The documentation of the HAZOP study is often facilitated by using a template. The team may modify the template based on their needs and record the identified deviations, consequences, causes, and recommended actions in the modified format.

Follow-up activities, such as implementing the suggested actions or re-studying elements of the process in case of any changes or updates, are facilitated by the HAZOP study report or document.

Why use HAZOP?

Safety is paramount in every working sector, making HAZOP a viable tool to address deviations found in complex processing systems. Whether it’s chemical manufacturing facilities or nuclear plants, this refinement technique is a safety tool to build a safe working environment, cultivate a system of growth, introduce problem-solving, and enhance productivity.

Advantages and Disadvantages of HAZOP

HAZOP is an invaluable tool when it comes to hazard analysis. In fact, there are several advantages that it holds unique to itself. The first one is its helpfulness when facing hazards that are difficult to measure, such as ones rooted in human behaviors and ones that are difficult to detect. The reason being because HAZOP doesn’t directly ask the risk management team to measure this kind of deviation from what is normal. Instead, they are required to use guide words that give them the ability to predict hazards before they occur.

HAZOP also has a built-in brainstorming method that helps with those hazard predictions. It relies on this aspect heavily. Lastly, HAZOP is a systematic and comprehensive method that is much simpler to use than other traditional risk assessment methods.

As for disadvantages, HAZOP does not have the ability to assess hazards regarding the interaction of different processes within systems. There is also no prioritization strategy that comes with a Hazard and Operability analysis. And lasty, there is no way that the users can assess the effectiveness of new or already existing controls.

With all that in mind, HAZOP is only one of the numerous methods that a company can use to find and solve hazardous situations within the workplace. It is also good to keep in mind that many of these types of methods can be used in tandem with each other to provide a more overreaching hand in keeping employees, equipment, and quality of product safe and efficient.

Examples of HAZOP Applications:

Some common examples of HAZOP applications are:

- Identifying potential hazards in a new chemical design

- Assessing the safety of an existing manufacturing process.

- Evaluating the effectiveness of newly introduced machinery in a standard procedure.

- Reviewing the procedure for handling hazardous materials.

Does OSHA Mandate A Hazard Assessment?

While OSHA does not impose HAZOP studies from organizations, it is interchangeably used as the Process Hazard Analysis (PHA) method, which is mandated by OSHA’s Process Safety Management (PSM) standard. This form of hazard assessment is used to identify, evaluate, control, and minimize risks and hazards within a facility.

Difference Between HAZOP And PHA

PHA (Process Hazard Analysis) is a broad approach to identifying and addressing defects and hazards within industrial procedures. Ideally, as required by the Occupational Health and Safety Administration, PHA is a safety net for facilities to avoid risks and financial litigations from workplace injuries. Meanwhile, HAZOP studies (Hazard and Operability Study) are a sub-category of PHA to identify risks and record deviations found within existing procedures.

In simple terms, process Hazard Analysis (PHA) is a thorough and systematic assessment of the potential hazards associated with an industrial process. Different methods including “bowtie” analysis, Fault Tree Analysis (FTA), Failure Mode and Effect Analysis (FMEA), Hazard and Operability studies (HAZOPs), and “What If” analyses are used to conduct PHA analysis. Thus, HAZOP is one of the techniques to perform PHA.

Difference Between HAZOP and Risk Assessment

While both HAZOP and risk assessment are safety techniques aimed at identifying and minimizing workplace hazards. With the exception that risk assessment is a broader approach designed to address hazards in various contexts, such as process safety, environmental impact, project management, etc. Unlike HAZOP, which is a systematic, structured approach used to identify and eliminate the likelihood of deviations found in existing processes or procedures during development.

How To Create A HAZOP Study?

HAZOP is a systematic approach to identifying potential safety hazards and operability problems in complex systems and processes. The following key steps are involved in creating and implementing a Hazard and Operability analysis.

Define the Purpose and Scope of the HAZOP Study

HAZOP analysis starts with defining the purpose and scope of the study. This involves identifying the process to be studied alongside the team members involved and any key assumptions or constraints of the study.

Assemble a HAZOP Team

The operability of the HAZOP method requires a team of experts in areas such as operations, maintenance, instrumentation, engineering, process design, etc. The ideal team size entirely depends on the process or procedure being evaluated but should be kept as small as possible without sacrificing the necessary talent or knowledge. The most common roles for this team are:

Study Leader: This person leads the study and should have experience with HAZOP studies already.

Recorder / Scribe: This person documents everything about the study, including causes, consequences, actions, deviations, and more.

Process Designer: This person provides details about the intent of designs.

Operator: This person will operate the process.

Specialist: This person provides specialized technological knowledge about the process.

Maintainer: This person offers information and details about the maintenance of equipment or other machinery.

Break down the System or Process into Nodes

Once a process or system is selected for HAZOP study, it is important to break it down into smaller units called nodes. Each node represents a specific point in the project under study, such as equipment, a control system, or an operating procedure, where potential hazards or operability issues can arise.

Identify the Process Parameters

The HAZOP team identifies process parameters for each node based on the scope and objectives of the study. These parameters can be physical properties such as temperature, pressure, level, or composition, or a functional property, such as current, frequency, or speed.

Apply the Guide Words

In this stage, the HAZOP team selects guide words for each parameter of each node, using a standard and systematic approach. These guide words are used to identify potential deviations from the intended design or operation of the system or process under study. Some common guide words used in HAZOP analyses are: no or not, more, less, as well as, part of, other than, early, late, before, and after.

Consider Consequences, Causes, and Safeguards

The HAZOP team considers the causes, consequences, and safeguards for each deviation identified in the earlier stage.

The consequences can include harm to workers, damage to equipment or environment, or loss of efficiency or productivity. Causes can include faulty equipment, human errors, hazardous chemicals, or external factors, such as power outages or unfavorable weather conditions.

Safeguards can include both preventive and mitigative techniques, including engineering controls, alarms, safety procedures, or training.

Document the HAZOP Study Findings

The HAZOP team prepares a detailed report to record the study findings. This document records the process studied, the nodes, parameters, guide words, deviations, evaluations, and recommendations for mitigating or eliminating the safety hazards and operability problems.

Review and Implement the Recommendations

The results of the Hazard and Operability analysis are reviewed with the relevant stakeholders to verify the findings. After verification, the recommendations are implemented to improve the safety and efficiency of the system or process.

The HAZOP study process may be repeated periodically to ensure any changes or updates to the system or process are properly analyzed to prevent hazards and operability problems.

Design A Safety Strategy Using HAZOP With Creative Safety Supply

Developing your own personalized HAZOP study can be a challenge in the initial stage. To help simplify the process, Creative Safety Supply offers custom safety signs where you can incorporate HAZOP guide words in compliance with your HAZOP study. Take advantage of our informative resources and long-lasting industrial signs and labels to transform your organization's capabilities into organizational excellence.

Similar Articles

- Job Hazard Analysis: Addressing Coronavirus Risk in Your Workplace

- Fault Tree Analysis

- Bottleneck Analysis

- Job Safety Analysis

- The Five Whys (Root Cause Analysis)

- What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

- Understanding Risk Assessments in the Workplace

- Value Stream Mapping (VSM Analysis)

- Kano Model (Analysis & Diagram)

- Hierarchy of Controls [Hazard Exposure + Prevention]