From MSDS to SDS

Chemical safety and communication standards, like OSHA's Hazard Communication Standard (HCS), are vital for protecting employees in workplaces involving hazardous chemicals. These standards ensure that employees have the right to know about hazards and how to protect themselves. In 2012, OSHA updated the HCS to align with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), leading to more consistent and understandable hazard information. As part of these changes, Material Safety Data Sheets (MSDS) changed and became the currently used Safety Data Sheets (SDS).

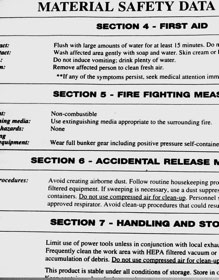

Image Credit: Jeffery Vinocur - An example SDS in a US format provides guidance for handling a hazardous substance and information on its composition and properties.

What Are MSDS and When Did They Start?

A Material Safety Data Sheet (MSDS) is a document that provides detailed information about the hazards of a chemical substance or product, and how to safely handle, store, and dispose of it. It's a crucial resource for workplace safety, ensuring that workers are informed about potential risks and how to protect themselves.

MSDSs were introduced in the mid-1980s by OSHA as part of the Right to Know provisions of its Hazard Communication Standard (HCS), also known as HazCom. OSHA mandated that each employer in the manufacturing industry obtain and maintain copies of MSDSs for each hazardous chemical used in their facility.

Issues with MSDS and the Transition to SDS

The primary issue with Material Safety Data Sheets (MSDSs) that led to their replacement with Safety Data Sheets (SDSs) was a lack of standardization and consistency. When OSHA or anyone else reviewed MSDS in multiple facilities for the same chemical, they found that they looked entirely different. This was clearly a problem since companies were not following any single standard, which made communicating about hazardous chemicals challenging.

In 2012, OSHA decided to make an update to its HCS or HazCom based on GHS, and it is where safety data sheets (SDS) were first standardized across facilities.

What Are SDSs?

Safety Data Sheets (SDSs) are the newer and more standardized version of MSDSs, adhering to the Globally Harmonized System (GHS). The main purpose of formalizing the safety data sheets was to make sure that employees in all facilities would see a single format with standard information for the hazardous chemicals they work with. Standardizing this information from MSDS to SDS makes it easier for people to understand, and therefore more effective at keeping people safe.

What Information is on a Safety Data Sheet?

Safety data sheets contain different information in different countries, though the information included is typically quite similar. In the United States, OSHA sets requirements for what information is on the data sheets and when data sheets are needed.

These sheets should have descriptions of all of the physical and chemical properties of the chemical. To put it simply, they should contain all useful information about a particular chemical. In many cases they will have information about toxicity, flash points, health hazards, guidelines for dealing with spills or leaks, requirements for storage, requirements for disposal, and much more.

In order to qualify as a safety data sheet, an SDS must include all 16 of the required sections. The sections are:

- Identification - Identifies the chemical that the SDS is for, which includes such information as the chemical name, manufacturer, distributer, recommended uses, restrictions for use, and more. This section should also include the phone number, emergency phone number, and address of the manufacturer or distributer.

- Hazard Identification - This is a list of all the hazards associated with the chemical. In this section is a list of any hazard label requirements.

- Composition - Here is a list of the ingredients of the chemical. Any trade secret claims also should be listed in this section.

- First Aid Measures - Detailed information about any first aid that should be given, and when. For example, instructions for what to do if the skin is exposed to the chemical. Also in this section are symptoms or effects (including acute, delayed, etc.) from exposure to the chemical.

- Fire-Fighting Measures - Information about the impact to the chemical if it catches on fire, how to extinguish a fire, and more.

- Accidental Release Measures - Instructions for what to do should there be an accidental release of the chemical. How to contain it, how to clean it up, what protective equipment is needed, etc.

- Handling/Storage - List of instructions for safe handling and storage of the chemical. Any precautions that must be taken are listed here too.

- Exposure Control - Here is information from OSHA's permissible exposure limits. Any threshold limit values, engineering controls, and what type of personal protective equipment should be used when working with the chemical.

- Physical/Chemical Properties - Detailed information about the characteristics of the chemical.

- Stability and Reactivity Information - A list of all chemical stability information as well as any possible hazardous reactions that could occur.

- Toxicological Information - Notes for how someone could be exposed to this chemical, symptoms of exposure, etc.

- Ecological Information - Information about what impact this chemical can have on the environment, especially if it gets into a water supply.

- Disposal Information - Proper instructions for how to safely dispose of the chemical, including any special restrictions or requirements.

- Transport Considerations - Instructions for how to safely transport the chemical.

- Regulatory Information - All information related to the regulatory requirements of the chemical.

- Other Information - This section is for other information that may be needed that doesn't fit into the other sections. Things like the date when the chemical arrived or the date when it was prepared would go in this section.

The structured format of Safety Data Sheets (SDSs) with 16 specific sections and a defined order makes them more user-friendly and efficient for those needing quick access to information. This standardized approach ensures that vital information about chemicals, including their hazards, handling, and emergency procedures, is presented consistently, allowing users to locate specific details easily.

Upgrading to SDS

SDS upgrades are necessary to ensure compliance with updated regulations and provide more detailed and standardized information about chemical hazards. Therefore, all facilities must maintain up-to-date Safety Data Sheets (SDSs) for every chemical they use, as missing or outdated SDSs can result in serious OSHA violations, especially for those that are audited by OSHA. Maintaining up-to-date Safety Data Sheets (SDSs) can also help minimize the risks of accidents related to chemicals and minimize the impact if an event occurs.

- https://www.osha.gov/sites/default/files/publications/OSHA3514.pdf

- https://en.wikipedia.org/wiki/Safety_data_sheet#United_States

Similar Articles

- Safety Data Sheets (SDS)

- GHS: The Globally Harmonized System for Labeling [Updated 2019]

- GHS Label Information

- GHS Label Creation

- What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

- Process Safety Management

- Hazardous Materials Identification System (HMIS Labels)

- Fire Safety in the Workplace

- Job Safety Analysis

- Arc Flash Labeling (Updated)