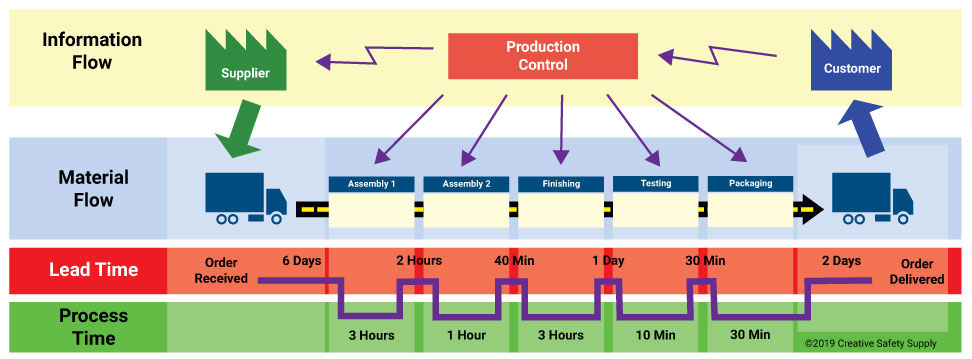

Value Stream Mapping (VSM) is a lean manufacturing technique used to visualize and analyze the flow of materials and information needed to bring a product or service to a customer. It strives to uncover areas where production can improve. VSM is a practice aimed at identifying every aspect of a business's processes and, from there, pinpointing where waste occurs. While you can limit/define the process at your discretion, it's best to map it from the supplier to the customer. Only after this discovery can you work to improve production and eliminate waste.

If an OEE calculation identifies that waste exists, then a VSM shines a light directly on the areas where waste occurs. From here, your team can work toward solutions. Without a VSM, you simply know that your company has waste, but not where it's coming from. Without that information, it's impossible to prevent it from happening in the future.

After you've created your VSM, you'll have a clear understanding of where waste is occurring, and you'll have a vision for what your future VSM will look like.

In this article, we will explore the key steps in value stream mapping, helping you understand the method and how you can use it to visualize and optimize your processes.

The Key Steps in Value Stream Mapping

Value stream mapping (VSM) involves various steps to visualize and analyze the flow of materials and information in a process, and ultimately eliminate waste and improve efficiency. Here are the core steps to follow:

Identify the Product/Service and Scope

It's important to have a specific idea of what to map. If you're a company that solely manufactures one product or family of products, you can focus on the entire process, but if you're a larger operation with many different products, it might be best to narrow the scope of the VSM and take smaller bites.

When narrowing the scope for a Value Stream Map (VSM), several approaches can be taken, including:

- Mapping a specific product or family of products

- Focusing on the most popular or highest-value products

- Targeting product ranges expected to increase in demand or value

Create Value Stream Mapping (VSM) Key

Since production processes are complex, it’s important to create a symbol key for Value Stream Maps (VSM) for clarity and efficiency in complex production process visualization. A well-designed key, using symbols instead of extensive text, will help make the map easier to understand, reduce clutter, and allow for a more comprehensive representation of the entire process.

Map the Current State

After defining the parameters for your process map, it’s time to outline your production process. It's crucial to list all the stages of production. It's important to be exhaustively thorough here. It helps to trace the final product back from the customer's hands to the supplier of raw materials.

Analyze the Current State VSM and Find Waste in Production

Once you have created the VSM, it will be easier to spot the type of waste in the production. Analyzing a current state VSM can help identify common problem areas within a production system, including:

- Excessive Inventory

- Long wait times

- Low uptime

- Excessive Setup Times

- Poor QA

When identifying and eliminating waste, such as long wait times in a production process, it's crucial to analyze cycle time versus wait time, focusing on the actual production steps. This involves observing the process firsthand, a technique called a gemba walk, rather than relying on past data. This hands-on approach helps pinpoint areas where improvements can be made.

Create an Ideal/Future State VSM

You have identified that there is quite a lot of waste in the current VSM in the form of wait time to deal with, but what to do now? What you really need here is a vision of what you want your production process to look like - an ideal state.

Now, to move from identifying waste in a current VSM to creating an ideal future state, you need to visualize a more efficient process. This involves developing a future state VSM that incorporates improvements to reduce waste, particularly wait times.

This future VSM is your immediate goal. It's the plan you'll be working toward to see new results within the next quarter. It can sometimes help to bring in an outside expert to help build this new map, and it's very important to communicate with senior management to make sure the future vision is agreed upon.

Other considerations when designing a future state VSM:

- Use of Kanban systems might remove the need for unnecessary planning and scheduling

- Use the Kaizen burst symbol to illustrate where improvements can be made

- Look into other Lean methods to help improve production

Develop an Action Plan

After you have constructed the ideal/future VSM, create a plan for implementing the changes needed to transition from the current state to the future state, including timelines, responsibilities, and resource allocation. This will help you ensure that the identified improvements are actually implemented and sustained.

Implement and Monitor

Now, you have the plan ready, it’s time to execute the plan and continuously monitor the implemented changes. So, put the action plan into motion and continuously monitor the results to ensure that the implemented changes are effective and that the value stream is improving. For this, you will need to track key performance indicators and make adjustments as needed.

Review and Update

Value stream mapping is not a one-time event; it's an ongoing process of continuous improvement. Therefore, regularly review and update the value stream map to reflect any changes in the process or new opportunities for improvement. This will help you ensure that the value stream mapping process remains a living document and a valuable tool for continuous improvement.

By following the above steps, you can effectively use value stream mapping (VSM) to identify areas for improvement, eliminate waste, and optimize your processes for increased efficiency and customer satisfaction. Make sure to involve key stakeholders from various departments and levels within your business or organization. This will help you ensure a comprehensive view of the process being mapped and facilitate buy-in for proposed improvements.

Similar Articles

- What is Process Mapping? [Definition, Examples & Tools]

- Bottleneck Analysis

- What is Toyota Lean Management?

- 5 Lean Principles for Process Improvement

- The Five Whys (Root Cause Analysis)

- Calculating Overall Equipment Effectiveness (OEE)

- Kano Model (Analysis & Diagram)

- DMAIC Cycle

- Hazard and Operability (HAZOP Analysis)

- What is a Kaizen Event? [Planning and Execution]