Working with electricity can be a complicated task, which is why it’s nothing short of critical to understand wire color codes. These standards primarily rely on color codes to ensure immediate identification throughout various industries. The NEC wire color code provides a glimpse into how to use color coding to assess the function of each wire. This system enables electricians to differentiate between live, neutral, and earth wires.

Let’s take a closer look at electrical wire color codes.

Understanding The Wire Color Code Chart

Wire color codes set a benchmark to ensure proper wiring during electrical projects or the manufacturing of electrical components. Here’s a rundown of general wire color codes:

Black Wires:

The main wire to look out for is the black one. The electrical wire color code dictates live wires with the color black, ensuring quick and immediate identification. Live wires, also known as hot wires, in residential systems carry the current from the main power source to the electrical appliance or outlet. Their prominent color code helps them stand out from the rest, requiring extra caution due to the increased risk of electric shock or electric hazards.

There is no single color code for live wires, and many countries use alternate colors to signify them. To avoid electrical hazards, it is recommended to treat black wires as “hot wires” or assume they are always electrically charged.

Red Wires:

Besides black, the next color to watch out for is red. In many electrical systems, red wires are used to identify secondary hot wires alongside black wires. Expect both wires to carry a lethal amount of current, and always switch off the primary source of electricity before disconnecting them.

Commonly found in 240 outlets and smoke detectors, red wires require a significant level of caution. Always test the wire to determine before proceeding with electrical work.

White And Gray Wires:

Not every wire present in electrical systems is designated to invoke caution. The NEC wire color code associates the color white with the neutral wires. This system is commonly used across U.S to help ensure a reliable system of electrical safety and communication.

Despite their name as neutral wires, it’s generally recommended to proceed with caution as they may carry a minimal current voltage. With the help of a wire tester, determine if the neutral wire is carrying a load of current.

Green Wires, Yellow-Green, Or Bare:

The electrical wire color code utilizes universal color codes for easy identification. Red or black is used to raise alarm, whereas green symbolizes safety and earth connection, setting the tone for grounded wires. In the US, the NEC wire color code is used to identify ground wires.

Blue and Yellow Wires:

A common sight in industrial and commercial electrical systems. Blue and yellow wires are used to carry current between three-way or four-way switches from poles. While they may not be a common sight, it’s best to treat them like every other live wire because they’re used to carry power from the primary source.

Orange, Brown, Pink, and Violet Wires:

Beyond the primary colors, you’ll find various hues like orange, brown, pink, and violet in different kinds of electrical circuits. You’ll see orange wires used instead of red wires, typically in 240-volt circuits where two hot wires are needed.

Among other colors, pink and violet are rare, but you should be aware of the threat they pose. Being live wires, they carry current within electrical circuits or are used in control wiring in dimming lights. In the UK or Europe, you’ll find brown wires in three-phase circuits or may discover them in your home’s electrical system.

With so many colors, it’s easy to lose track. A general rule of thumb would be to treat every wire as if it’s “hot” or “live.” This approach can help ensure your safety regardless of the specific electrical color codes your electrical system follows.

3-Phase Wire Color Codes

In commercial or industrial electrical systems, there are multiple sources of alternating current. To identify multiple wires, different electrical wire color codes are used to ensure proper wiring sequence. For outlets that carry 120, 208, or 240 volts, the following electrical wiring color standards are used:

-

Phase 1: Black

-

Phase 2: Red

-

Phase 3: Blue

-

Neutral: White

-

Ground: Green or green with yellow stripe.

2-Phase Wire Color Code

For systems with two live wires, known as 2-phase electrical systems, black or red color code are used to signify hot wires. Here’s a breakdown of the wire color code used in 2-phase electrical systems:

-

Phase 1: Red

-

Phase 2: Black

-

Phase 3: Blue

-

Neutral: White

-

Ground: Green or Green with yellow stripes.

Wire Color Coding Standards Around the World

The following table provides a comparison of the wire color code standards used in some of the most common countries:

|

Country |

Phase 1 |

Phase 2 |

Phase 3 |

Neutral |

Ground |

|

United States |

Black |

Red |

Blue |

White |

Green or Green/Yellow Stripe |

|

Canada |

Black |

Red |

Blue |

White |

Green or Green/Yellow Stripe |

|

United Kingdom |

Brown |

Black |

Red |

Blue |

Green/Yellow Stripe |

|

European Union |

Brown |

Black |

Grey |

Blue |

Green/Yellow Stripe |

|

Australia |

Brown |

Black |

Red |

Blue |

Green/Yellow Stripe |

|

India |

Brown |

Black |

Red |

Blue |

Green |

|

China |

Brown |

Black |

Red |

Blue |

Yellow/Green Stripe |

There are a number of different wire color code standards in place, so it is important to understand which color code to follow depending on the unique wire situation. The color coding standards used will vary based on the country where the electrical wiring is being done, the type of electricity used, and several other factors such as voltage, cables, connectors, switches, and circuits. The wire color code may vary from country to country.

-

The NEC (National Electrical Code) is followed in the US.

-

The CEC (Canadian Electrical Code) is followed in Canada.

-

The IEC (International Electrotechnical Commission) is followed in the UK.

Learning about the different color coding options that may be used in each electrically based situation is essential for workplace safety.

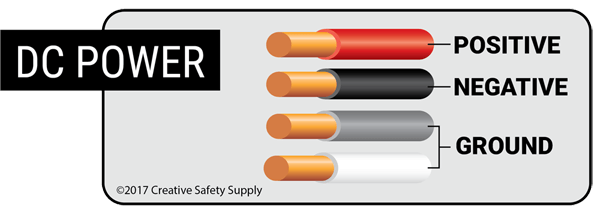

Wire Color Code For DC Power

Direct current power, or DC power, runs in a straight line through the electrical cable. While a more consistent form of voltage electrical delivery, DC power cannot travel the same long distances as AC electrical power. DC electrical power is used in battery, solar cells, and fuel cells, as a few examples. It can also be made from AC power with the help of a rectifier.

When wiring for DC electrical power, there are typically going to be either two or three insulated wires. The electrical color code is as follows:

-

The positive wire current must be red.

-

The negative wire current must be black.

-

The ground wire, if present, must be white or grey.

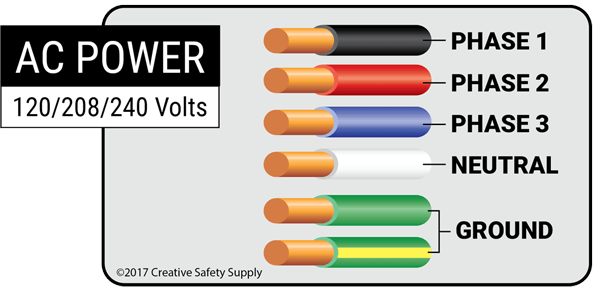

Wire Color Code for AC Power

Alternating current, or AC power, can be found in any electrical power outlet installed in most standard homes and businesses in the United States. This type of power circuit is unique in that the flow of charge can periodically change direction.

For wires that will be 120, 208, or 240 volts, the following electrical wiring color standards are used.

Phase 1 wiring should be black.

Phase 2 wiring should be red.

Phase 3 wiring should be blue.

Neutral wiring should be white.

Ground wiring can be green or green with a yellow stripe.

In some uncommon wire situations, one phase will have a higher voltage than the others. These are known as high-leg electrical connections. While rare, these wire switches can be identified by looking for a wire that is marked with orange, which will be the higher voltage wire.

Benefits Of Using Color-Coded Wires

Adhering to the respective wire color coding standards provides a range of benefits, including:

Enhanced Safety:

One of the most significant benefits of using color-coded wires is the enhanced safety it provides. By clearly distinguishing between different types of conductors, electricians, and homeowners can easily identify and avoid potential hazards. For instance, a hot wire can be quickly recognized, preventing accidental contact and electric shock.

Efficient Troubleshooting

These wires also simplify troubleshooting and maintenance tasks. When a problem arises, electricians can quickly trace the circuit path by following the color-coded wires. This reduces the time and effort required to diagnose and repair issues.

Reduced Errors

Color coding helps to minimize human error during electrical installations and repairs. By following the established wire color codes, electricians are less likely to make errors during installation or repairs.

Improved Organization

They also contribute to a more organized and visually appealing electrical system. The use of distinct colors can help to differentiate between different circuits and components, making it easier to understand and maintain the system.

Compliance with Standards

Adhering to wiring color codes is often a requirement for electrical installations to comply with local building codes and safety regulations. By using the appropriate colors, homeowners and businesses can ensure that their electrical systems meet these standards.

History of Wiring Color Codes

Wiring color codes have evolved over time to ensure safer and more efficient electrical systems. Initially, there was no standardization, leading to confusion and potential hazards. As electrical systems became more complex, standardized codes were introduced to establish guidelines for color usage in different types of wiring. These codes have continued to evolve to accommodate technological advancements and safety considerations, resulting in the well-established and widely followed color schemes used today.

Enhance Electrical Safety With Creative Safety Supply

Electrical wire color codes have been prevalent to protect workers, minimize risks, and ensure safe working conditions for everyone. To foster a culture of safety, we provide a range of electrical safety signs for immediate identification. At Creative Safety Supply, we believe your safety is paramount and provide solutions that prioritize your well-being.

Similar Articles

- Neutral Wire Color

- Electrical Wire Colors

- Safety Colors (OSHA Guidelines and Color Codes)

- ANSI Color Codes for Pipe Marking

- Pipe Color Codes – ANSI/ASME A13.1

- Labeling Electrical Conduits

- ANSI TIA 606-B Cable Labeling Standards

- Arc Flash and Electrical Safety

- 10 Essential Steps for Electrical Safety

- Heat Shrink Tubing