- The Best ToolBox Organization Ideas & Tips For Storing Your Tools

- Prepare Your Tools:

- Make Your Tool Box Organizer

- Multiple Bin Tool Box Organizer

- Tool Chest Organization Ideas

- Organization Ideas For Portable Tool Boxes

- Customize Your Own Tool Box Organizer

- 1) Create a Layout Before Cutting Foam

- 2) Make a Shadow Board for Your Tool Box

- 3) Use a Drywall T-Square to Draw Lines

- 4) Use the Right Tools for Cutting Foam

- 5) Cut Finger Holes for Easy Pick Up

- 6) Cut a Horizontal Strip for Easy Pick Up

- 7) Save Space by Putting Small Tools Close Together

- 8) Alternate Handle Directions to Save Even More Space

- 9) Don't Forget Spaces for Cords and Batteries

- 10) Use Thick Foam for Larger Tools

- 11) Cut Thick Foam with a Retractable Blade

- 12) Cut Out Shapes in Sections

- 13) Purchase Large Foam Sheets to Save Money

- 14) Use Foam Scraps as Tool Box Drawer Dividers

- 15) Make an Upright Wrench Organizer

- 16) Carve Custom Drawer Inserts with a Dremel

- 17) Color Coordinate for Tool Identification

- 18) Put Your Metal Tools in the Oven

- 19) Add Labels to Tool Box Foam

- Conclusion - Make Custom Tool Organizers Work for You

The Best ToolBox Organization Ideas & Tips For Storing Your Tools

Your handyman tools can help you correct a problem in your car or electrical system with just a screwdriver or a wrench. However, this is only possible if you find your tools in the first place. Scattered tools can be a problem when you most need them.

This guide will be a helpful tool if you're wondering how to organize your tools. Or you can choose to invest in a toolbox organizer and learn how to utilize your toolbox organizer with these convenient tool storage ideas.

Prepare Your Tools:

Organizing your tool chest is no easy feat when it seems so much easier to dump them aimlessly. However, if you want to begin learning how to organize your tool chest like a pro, the first step would be to separate them.

You can choose to separate your tools according to purpose or choose to keep similar tools together. However, the latter can lead you to rummaging through the bucket or your toolbox organizer, to find the right kind of screwdriver. Once you’ve separated your tools, let’s move on to the next step.

Make Your Tool Box Organizer

The most convenient toolbox organizer is one that you can find in your own house. If you have some space in your garage shelves, take three buckets and dump your tools according to purpose or function. Bucket toolbox organizers are a great idea to organize your tools as you do not have to make much effort and you can carry the bucket from place to place.

This DIY tool organizer box can save you a trip from the market if you feel like skimping on a professional toolbox organizer.

Multiple Bin Tool Box Organizer

One of the best ways to store tools is by taking all the shoe boxes to make your own DIY toolbox organizer or purchasing some clear plastic bins. An open clear bin is the best inexpensive tool organization idea that you can implement at your workstation.

Or if you’re working on a project, you can organize your required tools in one DIY tool organizer and focus on the work at hand by saving time consumed in finding the right tools. Another convenient and best way to store tools is by using a label maker on your tool organizer buckets. While it’s easy to visually identify which tools are required where, with a label in front of your tool storage containers you can simply grab the bucket and take it to your workstation.

However, if you are a professional handyman or have a business that takes you to different places. We recommend getting a toolbox organizer and following our toolbox organization ideas to never leave a job incomplete because of a missing tool.

Tool Chest Organization Ideas

Purchasing a tool chest won't automatically teach you how to organize a tool chest like a pro. It’s important to know how many sliding drawers or whether you have sufficient tool storage containers. Refer to our tool chest organization idea list to know how to sort them accordingly.

- Sort your tools according to their function, type, and size, and how often you use them. For example, you can group hand tools like screwdrivers, wenches, and hammers.

- Organize your tool chest by placing heavier tools at the bottom and lighter tools on the top.

- Use clear plastic trays in your tool chest to help keep your drawers organized

- With the help of a label marker, mark your tool chest to identify where your tools are located at a glance.

- Enhance the accessibility of your tool chest by placing tolls you use frequently at the top and seasonal tools at the bottom.

- Essential tools like screwdrivers, hammers, nails, tape measures, and pencils can be placed at waist height for easy accessibility.

Organization Ideas For Portable Tool Boxes

A common toolbox organizer found in every home. Portable tool boxes are an easy tool storing place to keep your tools in one place. However, some homeowners fail to utilize portable tool organizers to fit their functions. Portable tool organizers aren't just meant to hold your tools but to keep them organized.

However, if you simply dump your tools and nails in your portable toolbox organizer then these toolbox organization ideas might be helpful to you.

- Utilize the drawers of the toolbox organizer and keep your most used tools in the top sliding trays.

- In large portable toolboxes, you’ll find sliding drawers that act as a tool organizer to help you quickly locate the tools for your DIY electrical jobs or woodworking projects.

- Use a magnet to locate the small screws or nails in your toolbox to prevent stabbing your hand accidentally.

- Most importantly, your portable toolbox is meant to store only a few selective essential tools. So avoid dumping unsuitable large tools like a drilling machine into your toolbox.

Customize Your Own Tool Box Organizer

In many cases, the best tool box organizer is the one you customize yourself. Toolboxes and tool chests are all a little different, and the ways people use tools and the frequency with which they use them vary. The first step to getting organized is selecting a foam tool kit or other tool foam product. Then you can tailor this foam to fit your needs. You can create a single tool tray organizer or drawer organizer. You can also cut foam for every drawer in your tool chest.

To help you find the perfect tool organization solution, we've put together a list of 19 tips and hacks to inspire you.

1) Create a Layout Before Cutting Foam

No matter what type of foam liner you're working with, you'll likely have to cut it to fit the drawers of your tool chest and to fit your tools. To maximize your foam and achieve the best possible layout, don't start cutting until you have a plan.

First, lay out every tool you want in a drawer on top of the foam. Stop and consider what the best arrangement and sort order will be. Try putting tools you use together near each other. You might want to place tools you use more frequently closer to the front of a drawer were you can access them more quickly. Once you have the layout you want, trace all the tools using a pen, pencil, or marker. Then you can start cutting.

This tip sounds simple, but it's some of the best advice about cutting tool foam. If you start cutting without a plan, you're more likely to space tools poorly and end up wasting material.

2) Make a Shadow Board for Your Tool Box

Toolbox and packout foam comes in several styles, sizes, and colors. Some types of foam are single color - often called foam drawer liners - and some contain stackable two color arrangements. These foam tool organizer kits with two colors have a dark top layer of foam (usually black or blue) and a bright bottom layer. When you cut out the shapes of your tools on the top layer and place it over the second layer, that bright second layer shows through. This arrangement functions like a shadow board (which people tend to associate with tools mounted or hanging on walls; whenever a tool is missing from your drawer, you'll know immediately it's not where it belongs.

3) Use a Drywall T-Square to Draw Lines

When you outline small tools, drawing straight lines probably won't be a concern. You can easily trace the tool itself. If you need to draw long, straight lines to cut a piece of tool foam to size, though, a straight edge such as a drywall T-square can make the task a lot simpler.

Align the short end of the T-square with the edge of your foam and cut along the length of the device. Your edges will be perfectly straight, so your tool box foam inserts will fit snuggly into the drawers of your tool box.

4) Use the Right Tools for Cutting Foam

Most foam tool organizers and tool foam sheets are made from cross-link, closed-cell foam, designed to resist water, and stand up to harsh chemicals and oil. They're made from durable materials, but that doesn't mean cutting the foam will be too difficult. You just need the right tools.

In most cases, a simple tool such as a utility blade or X-Acto knife can cut your tool foam. These blades are fairly small, which allows you to cut small shapes without too much trouble.

You can also use a heavy-duty foam hot knife for foam cutting. You can make clean, precise cuts with these knives. They're helpful for large cutting projects and for cutting through thick foam.

5) Cut Finger Holes for Easy Pick Up

If a tool fits snugly into tool box foam, it can be difficult to pick it up quickly. You don't want to leave too much space around a tool because it could slide around, though. An effective way to fix this problem is to cut a semi-circle on each side of a tool's handle that lets you reach in and grab it.

You can cut this circle with a knife, but it's even easier to do so with a hole punch (the metal kind you would use to cut perfect circles in plastic, leather, wood, and other materials). Before you punch the hole for a tool, though, make sure you cut out all the shapes on your foam sheet. This way you can assess the space you have and figure out the most logical place to put the hole for easy tool pick up.

6) Cut a Horizontal Strip for Easy Pick Up

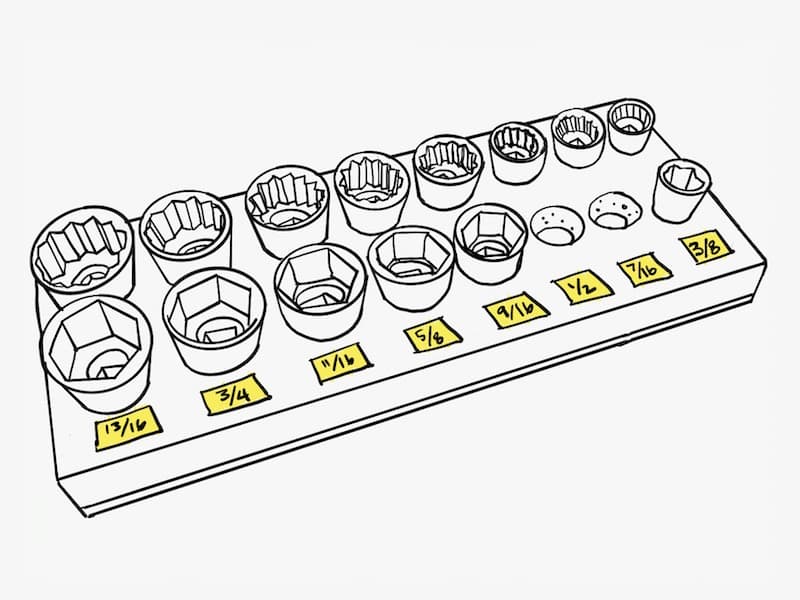

In some situations it makes more sense to cut a strip through all of the tools in a drawer so you can pick any of them up easily. This works if you have a drawer of wrenches, for example, where you have wrenches of many sizes placed close together. The wrenches might be too close together to use the hole punch method, and the horizontal strip method will likely create a cleaner finished product.

7) Save Space by Putting Small Tools Close Together

Tool box foam sheets work great for organizing smaller tools that would otherwise be thrown together in a drawer. When these tools are neatly arranged using foam, you can find the size you need without digging through a jumble of tools. This method is useful for creating DIY wrench organizers, socket organizers, and screwdriver organizers. You can see an example of a pliers organizer below.

8) Alternate Handle Directions to Save Even More Space

Another method for organizing drawers with small tools is to alternate the direction of tools to maximize space. This works well for pliers, screwdrivers, and other tools with a narrow end and a wider end with a handle.

9) Don't Forget Spaces for Cords and Batteries

When you plan tool box foam layouts for power tools, don't forget to make spaces for cords and batteries. Cutting out spaces for these accessories will prevent them from getting lost and it will prevent damage to cords. Cutouts for cords don't need to be perfectly shaped, but they do need to be big enough to fit the cord. Make sure to lay the cord out and trace it so you'll be able to fit it into the space without trouble in the future.

10) Use Thick Foam for Larger Tools

Foam tool kits work well for small to medium-sized tools, but for larger tools such as drills you'll probably need thicker foam. It also makes sense to use this thick foam in the deeper drawers of your tool chest so tools don't sit too low in the drawers.

Thick tool control foam is often constructed of thinner layered foam sheets glued together, so you can cut out several of the layers and fit a tool into the foam without cutting all the way through the foam. This means your tools will be protected from damage on the bottom, too.

11) Cut Thick Foam with a Retractable Blade

Using a retractable blade to cut thick foam will help you cut out the exact depth you need without cutting through the foam. Before you start cutting, measure the blade against the side of the object you want to place in the foam. Make sure the blade depth matches the depth of the object. Then you can start cutting.

12) Cut Out Shapes in Sections

For some tool shapes, it will be easier to cut out the foam in sections rather than cutting out an entire shape at once. This is usually wise when you're cutting out large shapes. It's also useful when you cut out intricate shapes and want to be careful not to tear the foam. To begin, try cutting out small sections at a time. Move slowly along the shape in a way that makes the most sense. Whatever method you use, avoid trying to remove shapes too quickly, as doing so can cause damage.

13) Purchase Large Foam Sheets to Save Money

You can purchase foam tool kits or foam drawer liners sized to fit the drawers of your tool box. If you plan to use foam in many drawers, though, it's often more economical to buy a large foam sheet or foam kit and then cut it to fit several drawers. You'll probably have some foam scraps left over after your project, but you'll also probably spend less money.

14) Use Foam Scraps as Tool Box Drawer Dividers

You might have small objects you store in your tool box that don't need their own cutouts and can be stored as a group. Maybe you'd like a small square section of a drawer where you can keep screws or nails while you work. To create a divided space, try using foam scraps. Cut thin strips of foam and turn them vertically so they serve as dividers. These DIY tool chest drawer dividers will serve a unique function and use up some of those foam scraps you otherwise wouldn't have a use for.

You can also use scraps of foam as padding around the edges of drawers.

15) Make an Upright Wrench Organizer

Another way to save space in your tool chest is to turn both foam and tools on their sides and create an upright tool organizer. This works well for smaller tools such as wrenches, as you can see in the image below. It can even provide the extra space to store both your metric and standard wrenches.

16) Carve Custom Drawer Inserts with a Dremel

If you have a Dremel rotary tool with a depth accessory, you can turn it into a plunge router to carve out spaces in your tool foam. This will take you beyond having a foam cutting tool to having a foam shaping tool capable of more detailed work. This is useful when you want to carve into thick sheets of foam or when you want to have a very snug fit for you tools. When you use your Dremel as a plunge router, you can cut varying depths into the foam so it molds to your tools, making for a very custom fit.

To do this, install a multipurpose bit in your Dremel and then screw a depth accessory over it (Dremel rotary attachment part number 565 or 566, depending on which model Dremel you have). By adjusting the depth accessory as needed, you can then carve out foam using the bit. To achieve the best fit for your tools, carve slowly to get the shape and depth you want and test out how the tool fits the shape as you go along.

While this method of cutting foam is ideal for thick layers of foam, you can also use it to cut into two-layered foam tool kits. You might want to do this to get a snug fit for taller tools while still having the shadow board effect with a bright background layer.

17) Color Coordinate for Tool Identification

When you store more than one kind of tool in a drawer, you might want to consider using different colors of tool box foam inserts for the sections where you will store different tools. For example, you could use blue foam for screwdrivers and black foam for pliers. If you use foam tool kits with two layers, the entire top layer could be black and the bottom layer could incorporate several colors of foam such as red and yellow. That way people can see even from a short distance away whether a screwdriver or pliers is missing from the drawer.

18) Put Your Metal Tools in the Oven

This might sound bizarre, but if you don't like tracing, here's an alternative for outlining tools on foam that involves an oven. Keep in mind, this only works for tools without rubber or plastic parts.

First, mark where you want your tools on your foam (even if you don't trace them, at least indicate their general position). Then 'œbake' your tools on a cookie sheet for 30 minutes in a 350-degree oven. Carefully remove the hot tools one by one and place them on the foam sheet. The tools will melt the foam beneath them, creating indentations. (If you don't have access to an oven, you could also try using a toaster oven or heat gun to heat up the tools.)

Once the tools and foam have cooled, remove the tools and cut out the imprinted shapes.

19) Add Labels to Tool Box Foam

The methods we've described above for using bright colored foam to highlight missing tools help people identify where tools belong. It can also be helpful in shared tool storage areas to add small labels next to each tool's cutout naming the tool. This can make finding and returning tools even faster, especially for people who may be less familiar with the current tool arrangement or the tools used.

Labels of this nature can also be placed on the outside of tool drawers, tool chests, and tool storage cabinets so people can find the type of tool they're looking for.

Conclusion - Make Custom Tool Organizers Work for You

An organized space tends to be a more productive space where fewer mistakes are made, and organizing your tools is a simple way to make your space an easier place to get work done. All spaces are unique, though, which is what makes a customizable organizational tool like tool box foam a solution that can work for almost anyone.

To get started, find appropriate foam products. We recommend checking out foam tool organizers (which come with two sheets of contrasting colored foam), foam drawer liners (a single sheet of foam), and thick foam tool organizers (for deeper drawers or larger tools). You can also get the appropriate foam cutting accessories (https://www.creativesafetysupply.com/foam-cutting-accessories/), too.

Have questions about selecting or using tool foam organizers? Get in touch. We're happy to help you find organizational tools for your project.