- What is Fault Tree Analysis?

- Steps for Fault Tree Analysis

- History of Fault Tree Analysis

- What is Fault Tree Analysis Used for?

- Using Fault Tree Analysis

- Fault Tree Symbols

- Fault Tree Analysis Template

- Fault Tree Diagram

- Fault Tree Analysis Tools

- What is the Difference Between Fault Tree Analysis and FMEA?

- Fault Tree Analysis Training

Risks plague working environments constantly if not properly managed from the beginning. Luckily this can be resolved with the help of Fault Tree Analysis. Using FTA is often easier than Failure Mode and Effects Analysis because it works to look at problems within any system in a top-down way. FTA doesn’t exhaustively categorize all risks like FMEA does either, rather it only focuses on one or a small handful of initiating faults at a time.

What is Fault Tree Analysis?

The Fault Tree Analysis strategy is a failure analysis option that uses deductive reasoning in order to discover the root cause of an issue. Once that root cause is found, it can then be resolved as quickly and efficiently as possible to help preserve quality. FTA is most commonly used in engineering, safety, and manufacturing environments, though it can be applied to just about any situation. By looking at how a system can fail, Fault Tree Analysis is able to help determine what steps can be taken to reduce the risk of problems.

While Fault Tree Analysis can certainly be used to investigate a known issue, it is best for finding problems before they occur. By creating a "tree" that looks at each area where there is potential for issues, companies can take preventative action to either keep those problems from happening at all or reduce the impact of the issue should it occur. This is why FTA is such a popular option for high-risk environments where any type of problem could cause catastrophic issues.

Steps for Fault Tree Analysis

There are five steps to performing this method effectively in all sorts of working environments. They are as follows:

- Identify the undesired event

- The hazard should be described as in depth as possible. Consider the impact regarding safety, the environment, and all regulatory consequences. Also determine how much and how long those impacts will be present for.

- Work to understand the current system

- Gather all the appropriate supporting information such as a list of components, a boundary diagram, schematics, code requirements, etc.

- Gather input from reliability and design engineers to determine the causes of the hazard.

- Estimate the probability of those causes that ultimately lead to the hazard.

- Organize for probability in order of occurrence.

- Create the fault tree

- Use fault tree symbols to create the fault tree diagram.

- Evaluate

- Determine the level of risk involved with each addition to the fault tree. The causes that are considered to be at the highest risk must be chosen to employ mitigation techniques.

- Control the identified hazards

- This last step is often the one that changes the most within each unique industrial working site. These mitigation efforts can include actions involving design changes, substitution or replacing dangerous equipment, employing physical redundancy for certain components, using software redundancy, employing a warning system, or using quality control techniques.

Going through each of these steps is critical for the FTA process. These steps are also what makes FTA unique from other problem solving and hazard identification methods. Overall, the identification of potential failure is important to not only mitigate that risk from ever occurring, but it also works to prevent giving customers an unsatisfactory experience.

History of Fault Tree Analysis

Many of the strategies utilized in Fault Tree Analysis have been used by people for hundreds of years. The more formalized system, however, was first developed in 1962 by Bell Laboratories. It was done for a US Air Force Ballistics Systems Division contract where they wanted to evaluate certain systems. This included the launch control system for the Minuteman I Intercontinental Ballistic Missile.

Over the course of several years, FTA was updated and improved, often thanks to defense contracts with various companies. The US military is a strong proponent of the system because of the extremely high level of importance regarding many of their projects. In that type of industry, when things go wrong with a military project it can cost millions of dollars, or worse, cost people their lives. This points to the reason why FTA is used so often in those situations.

In addition to being used for US Military projects, it has also been taken advantage of by the federal aviation administration, air traffic control, the US National Airspace System, the US Nuclear Regulatory Commission, and many more. This is in addition to the thousands of private companies that have been implementing this system in their facilities for years.

What is Fault Tree Analysis Used for?

Ideally Fault Tree Analysis should be done as early and often as possible. In many cases, it can be done before the system being analyzed is even up and running. Looking at each step along the way to discover potential risks, and addressing them ahead of time, is a great way to avoid problems down the road.

Even existing systems can be analyzed using this strategy to discover risk potential. When done properly, the Fault Tree Analysis strategy can help to accomplish the following goals:

- Learn more abhow a pout articular event took place.

- Diagnose the cause of known issues.

- Help to design a new system.

- Optimize resource consumption.

- Predict potential safety concerns.

- Eliminate wasted steps in a process.

- Improve efficiency.

- Evaluate safety or regulatory compliance.

There are many other things that Fault Tree Analysis can help with. In the end, the data that can be gathered from this type of system can be invaluable to a company no matter what they are using it for.

Using Fault Tree Analysis

Putting the FTA method into practice can be a bit more difficult than it seems in comparison to when explaining it on paper. Now, there are a handful of disadvantages of using this method that must be taken into account before it is chosen by those who will be working with it. These consist of:

- There are too many gates and events that need to be considered for the analysis to be carried out on larger systems.

- It examines only one top event or undesired outcome.

- Existing common cause failures are not always as obvious when using FTA.

- Time and delaying factors are often harder to measure.

- FTA requires highly knowledgeable people and engineers to fully understand all existing logical gates.

With those in mind, the user must prepare for this method appropriately with the steps mentioned above. The following sections will go over the smaller intricacies on how to use Fault Tree Analysis.

Fault Tree Symbols

The first thing that the user must be familiar with are all the symbols that can appear on an FTA diagram. Referred to as “logical gates,” these symbols provide an understanding of root causes that affect the identified unwanted outcome. Fault Tree Symbols come in two categories:

- Event Symbols

- A Basic Event – The failure of a system component.

- An External Event – An event that is expected to occur normally, but it is not considered a fault.

- A Conditioning Event – Conditions that work to restrict the below logic gates.

- An Undeveloped Event – An event that causes no consequences or doesn’t have enough data.

- Gate Symbols

- OR Gate – When at least one of the input events take place, the following undesired event occurs.

- AND Gate – Only if all events classified as inputs happened, does the undesired event occur.

- Exclusive OR Gate – The event occurs only if one of the conditions takes place, not all of them.

- Priority AND Gate – The event only occurs if the sequence of conditions have taken place.

- Inhibit Gate – The event will only occur is all inputs have taken place as well as the conditional events.

The above logical gates each have a symbol that will hold a piece of relevant information. The utilization of symbols makes explaining events more intuitive and recognizable, rather than the chart being uniform and filled with text.

Fault Tree Analysis Template

One of the easiest and most effective ways to begin the Fault Tree Analysis process is to use a template. These templates can be filled out quickly based on the information available at the time. When using them, it will help to gather information in an easy-to-understand format that can be referred back to at a later point to determine what type of solutions can be implemented.

There are many formats that a Fault Tree Analysis template can take. Many of them will be stored on a computer or mobile device so that information can be added into the template quickly and easily.

Other templates are printed off so that the person or group doing the analysis can write on it using a pen. Whatever option is used, templates will typically just be a first draft where notes and information are taken down.

Once all the initial information has been gathered, it can be transferred into a more organized and even visual option, such as a Fault Tree Analysis diagram.

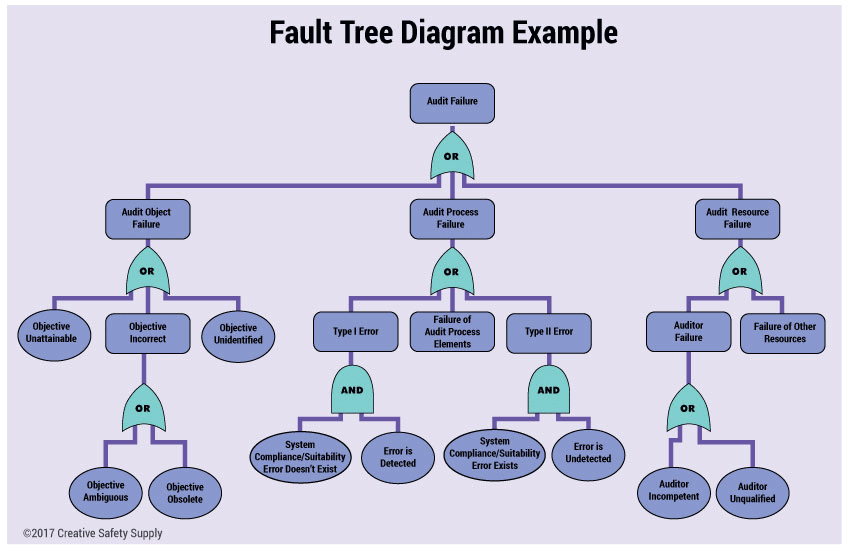

Fault Tree Diagram

Once the initial fault tree analysis has been completed and all the information has been gathered, it can be entered into a fault tree diagram. This helps to organize all the information together in an easy-to-understand way. One example of a fault tree diagram can be seen below. Of course, there are many different ways that a diagram can be made based on the specific needs of a facility.

From the diagram, it is possible to come up with potential solutions to problems that were discovered during the FTA process. The diagram will be able to point out different risk areas, and what potential issues could occur.

Using this information, companies can often avoid a wide range of problems that could have otherwise taken place. Sometimes the issues are simple, such as a machine breaking down due to worn parts. By identifying this type of risk, a facility can replace the parts ahead of time. This will ensure there is only a planned maintenance outage rather than an unexpected outage due to the machine breaking down. Regular system upkeep is incredibly important for an efficient facility.

Fault Tree Analysis Tools

To make it faster, easier, and more effective to use the Fault Tree Analysis process, many companies will invest in tools that will streamline the process. Good Fault Tree Analysis tools will typically be some type of computer software that can generate a diagram and keep track of all the information gathered during the analysis itself.

This type of tool can be updated and adjusted over time to ensure it is always up to date with the latest changes that take place within a facility. This type of tool can also be used in the planning of changes and improvements within a facility. By taking the data from the Fault Tree Analysis, a company can decide what the most pressing needs are and invest funds or other resources in that direction. With that being said, FTA is an excellent tool to work into a Six Sigma program.

As things change within the different processes in the facility, the tool will help keep everything updated so that it offers the best information possible at all times. While it is possible to perform Fault Tree Analyses without any type of tools, they do make it much easier and more effective.

What is the Difference Between Fault Tree Analysis and FMEA?

The only ideas that both FTA and FMEA have in common are that they are excellent resources and tools when it comes to finding and solving risks present in the workplace. Both however, have very different ways of going about this kind of business.

The most prominent difference between the two systems is that FTA is a top-down method whereas FMEA has a bottom-up system going. As mentioned before, a Fault Tree Analysis will take the failure itself initially and work down to what the root causes might be. On the other hand, Failure Mode and Effects Analysis takes every single component and works on possible failure outcomes. The latter is a more exhaustive approach to productive maintenance and problematic events than FTA.

The next other defining factor between these two systems is that FMEA tries to predict all failures for each mechanical or other component. It also doesn’t take into account any conditions that may lead to other undesired outcomes like FTA. FTA also works harder on probability aspects of unwanted events.

The last, and certainly not the least, difference that FTA has with FMEA is that FTA is a quantitative tool. This is because FTA can be used to perform a Probabilistic Risk Assessment, unlike FMEA which is strictly a qualitative route for risk analysis.

Both FMEA and FTA are good resources to use but using them in the right environment will be the determiner for how safe and efficient maintenance and normal production becomes.

Fault Tree Analysis Training

When implementing Fault Tree Analysis in a facility, it is important to ensure everyone who will be using it is properly trained. Unlike many other analytical methods, this is a deductive, top-down approach that is very effective at informing about potentially complex systems and processes. Correctly implementing this strategy allows for the user to pull out essential information along the way, therefore giving them a better understanding of what is going on in the process.

As with many other analytical methods, FTA has a lot of terms and systems that need to be understood before the system can be effectively implemented in any facility. Not to mention that the system needs consistent upkeep for it to work continuously. There are always improvements to be made, and new undesired events may surface with time. Quality maintenance can be done by those who are familiar with the system and show the process to new employees. Training can often take place with 3rd party organizations as well.

Similar Articles

- The Five Whys (Root Cause Analysis)

- Bottleneck Analysis

- Hazard and Operability (HAZOP Analysis)

- Job Safety Analysis

- Job Hazard Analysis: Addressing Coronavirus Risk in Your Workplace

- Kano Model (Analysis & Diagram)

- 8D for Problem Solving

- Value Stream Mapping (VSM Analysis)

- Organizational Development Process

- Six Sigma Principles