The Occupational Safety and Health Administration, also known as OSHA, requires employers to keep their employees safe near electrical hazards. Part of this requirement includes using the appropriate markings in which to alert workers of potential electrical dangers, as well as keep the area in front of the equipment clear so work can be performed safely.

A simple way to meet electrical panel clearance requirements is to use floor markings. These markings can include floor marking tape, floor signs, and labels. With these tools, floor marking for electrical panel compliance can be accomplished without spending too much on time or effort.

OSHA Requirements for Electrical Panel Floor Markings

Before implementing any kind of marking strategy, employers must first understand the OSHA regulation related to electrical panel clearance. The regulation that we’re referring to is 1910.303. It specifically states, “sufficient access and working space shall be provided and maintained about all electric equipment to permit ready and safe operation and maintenance of such equipment.”

OSHA 1910.303 explains the exact safety measures you must take to protect your workers around electrical equipment. The following is a short summary of those rules:

- You must allow for sufficient working space.

- The width in front of the electrical panel must be either 30 inches or the width of the equipment. You must use the measurement that is greater in length.

- The space must allow for the electrical panel door to open at a 90-degree angle.

- The vertical space from the floor to the ceiling around the electrical panel must be 6.5 ft. in buildings that were constructed after August 13th, 2007.

- The working space directly in front of the electrical equipment varies by voltage, insulation, and any exposed live or ground wires. You can find this information in section 1910.303(h)(5)(vi) of the OSHA regulation.

According to the Congressional Accountability Office of Compliance, NFPA’s National Electric Code (NFPA 70 110.26) also requires a minimum clearance of 3 feet for electrical equipment with 600 volts or less.

Please take the time to read both OSHA and ANSI’s standards in their entirety! It is important that your facility follows the standards put forth by these electrical panel regulation as well as all the marking requirements. This will help you avoid any OSHA fines as well as prevent your workers from sustaining serious injuries or even death.

Why is Electrical Panel Clearance Important?

Did you know that electrical requirement violations are almost always within OSHA’s top ten types of citations annually? That being said, electrical panel clearance is necessary for three different reasons:

- It protects maintenance workers performing tasks

- It protects the equipment from damage

- Visible clearance in the form of floor marking keeps people out of the restricted zone

Overall, keeping the area clear where dangerous electrical equipment resides will prevent injuries and collisions. This type of clearance assists workers in staying safe, but it also keeps the electrical equipment from becoming damaged, which can result in thousands of dollars in repairs. Not to mention the downtime associated with a potential power outage.

Establishing Electrical Panel Boundaries with Floor Tape

Floor marking tapes can serve many additional purposes in the workplace. Businesses frequently choose to mark permanent aisles and passageways, walkways, exit routes, and other hazardous areas. Combined, these floor markings make it easier for people to navigate workspaces and perform tasks more efficiently. Floor markings like those used near electrical panels also enhance safety.

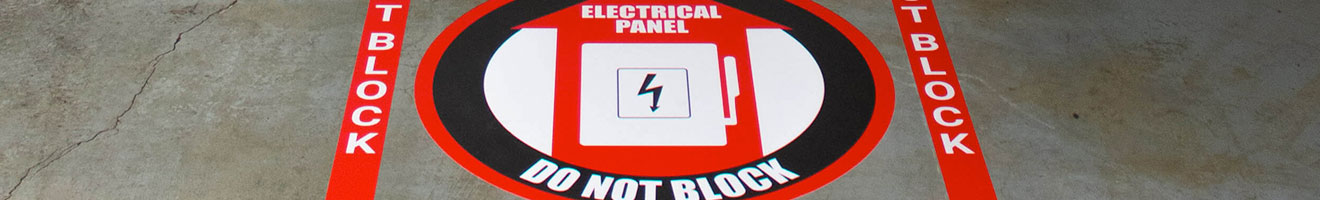

Floor signs stating that the area in front of an electrical panel must be “kept clear” are an effective method for complying with OSHA regulations. Multiple styles of floor signs exist for this purpose.

Floor signs like these, or labels conveying similar information, are key for communicating with employees. To ensure the necessary 36 inches of clearance are left in front of electrical panels and that a working width of 30 inches is present, many workplaces combine signs with floor marking tape. This tape can outline the area to provide clear visual borders around circuit breaker panels and electrical boxes.

The Best Practice Method for Floor Marking Tape Color Scheme

While specific colors of floor marking tape are not required, it’s often recommended that employers select colors that indicate a hazard is present. Striped black and yellow, or white and red floor marking tape often serves this purpose, as black and yellow are regularly used for general hazard markings and red and white hazard marking are often used for fire hazards.

Further information about colored floor tapes can be found in this Floor Marking Guide.

Floor Marking Resources from Creative Safety Supply

Creative Safety Supply is here for you! As the industry leaders in visual communication, we are the Lean manufacturing safety experts you can trust. Many facilities come to us looking to improve safety at their workplace, but they don’t know where to start.

Luckily for you, we’ve made it super easy to pick out the vinyl floor marking tapes you need without worrying about whether they’ll last the test of time, or go easy on the pocketbook, for that matter. Check out our floor tape finder today and explore your tape options for the unique facility you operate.

We also have several educational resources that can be downloaded for free! Check out our Electrical Panel Labeling Guide or our resource page specifically dedicated to visual safety and floor marking.

With these thorough pieces of information, you’ll become experts on how to label your facility in a way that keeps people safe and organized.

Similar Articles

- OSHA Floor Marking

- Floor Marking for Factories

- Improving Workplace Electrical Safety

- Floor Marking for Social Distancing

- Industrial Floor Marking Guidelines

- Floor marking comprehensive research, education and training

- Floor Marking for Facility Safety

- Floor Marking for Fire Extinguishers

- Types of Floor Marking

- Floor Marking for Forklift Traffic