The Eight Disciplines (8D) of problem solving is a model used to effectively identify and solve recurring problems. While most Lean tools are derived from the Toyota Production System, 8D was actually developed by the Ford Motor Company.

What is the 8D Problem Solving Process?

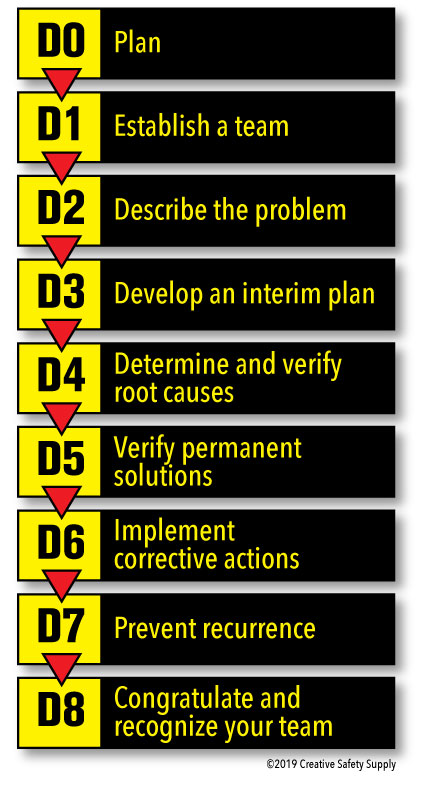

8D is made up of eight steps for problem solving, but many choose to include an additional step called D0. The disciplines are as follows:

D0: Plan how you will solve the problem. Gather the necessary information and identify prerequisites.

D0: Plan how you will solve the problem. Gather the necessary information and identify prerequisites.

D1: Establish a team with people who have knowledge of the product or process at hand.

D2: Describe the problem using quantifiable terms. Answer questions about who, what, when, where, why, how, etc.

D3: Develop an interim plan that will be put in place temporarily. Although it will not solve the problem, an interim containment plan that does not impact the customer can help to isolate the problem.

D4: Determine and verify root causes and all applicable reasons for why the problem has occurred. Use the 5 Whys or a Fishbone diagram to get to the bottom of the issue.

D5: Verify permanent solutions that are a long-term fix. The solution should resolve the problem for the customer and be verified through a series of tests and analyses.

D6: Implement corrective actions after they have been verified.

D7: Prevent recurrence by training workers, managing the solution, and documenting efforts.

D8: Congratulate and recognize your team for their efforts! It is important for workers to feel valued and can encourage them to get involved in future problem-solving processes.

8D & Lean Problem Solving

The Eight Disciplines offers a more in-depth methodology than its counterparts, the DMAIC model and the PDCA cycle. While all effective problem-solving techniques, 8D allows you to not only implement solutions but walks you through the identification of the root cause and development of long-term solutions that will not impact the customer. Before diving straight into 8D, you could complete a PDCA cycle or work through the DMAIC process and build upon these concepts by integrating steps from 8D into your work.

Similar Questions

- What are the 5 Whys?

- What are fishbone diagrams?

- Which automobile company initialized Lean manufacturing?

- What is Lean engineering?

- What are Lean terms?

- What is a Lean Six Sigma Black Belt?

- What is the Lean manufacturing process?

- When was Lean manufacturing invented?

- What are bottlenecks and how can I fix them?