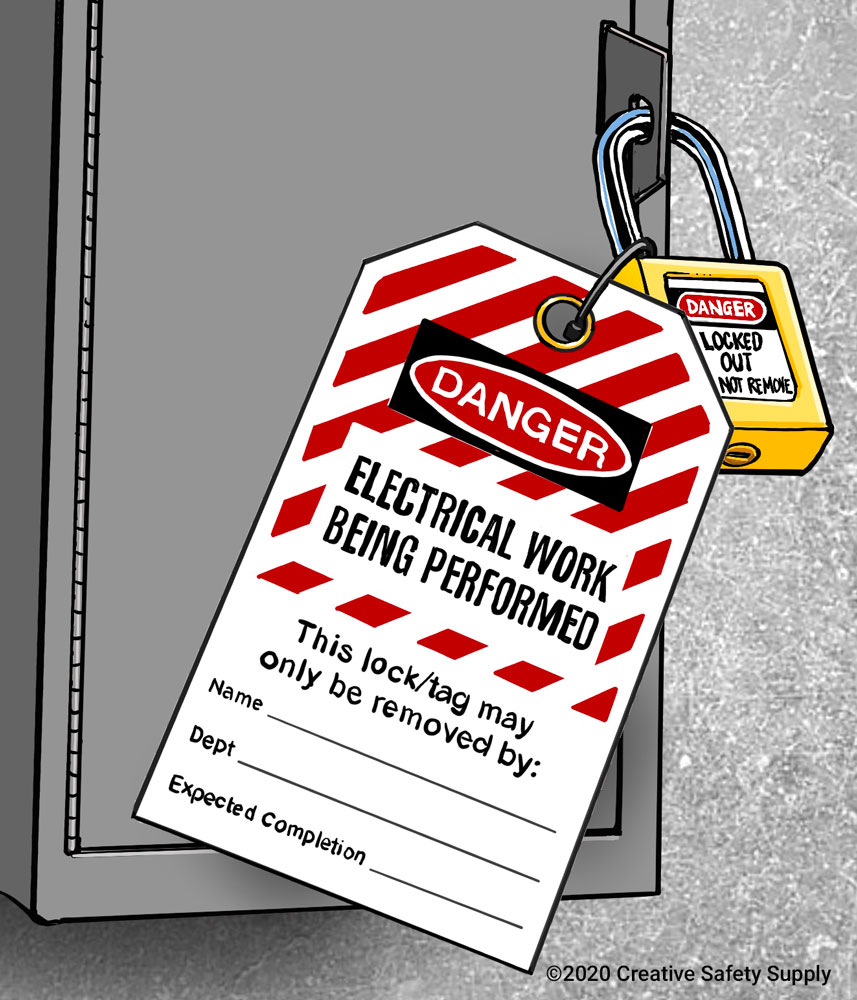

Lockout/tagout tags are safety devices that warn workers about the status of machines or equipment that are undergoing servicing or maintenance. Lockout/tagout tags are part of a system of lockout/tagout (LOTO) procedures that aim to prevent the unexpected startup or release of hazardous energy that could cause harm to workers or damage to equipment. Lockout/tagout tags are attached to the energy isolation devices that secure machinery or equipment in a safe or off position. Lockout/tagout tags provide information such as:

- The identity of the authorized employee who applied the lockout/tagout device and is responsible for the servicing or maintenance of the equipment.

- The reason for the lockout/tagout, such as repair, inspection, cleaning, or adjustment.

- The date and time of the lockout/tagout application and the expected duration of the servicing or maintenance activity.

- Any additional warnings or instructions, such as “Do Not Start”, “Do Not Open”, “Do Not Close”, “Do Not Energize”, or “Do Not Operate”.

What is a LOTO Tag?

Lockout/tagout tags can come in a variety of different designs. They have signal words, such as “Danger”, “Caution”, or “Warning”, and colors, such as red, yellow, or orange, to indicate the level of hazard and the required precautions. Lockout/tagout tags must be legible, durable, substantial, and identifiable, according to the Occupational Safety and Health Administration (OSHA) standards.

Lockout/tagout tags help protect workers from the risks of injury or death caused by the accidental or unauthorized startup or release of hazardous energy from machines or equipment. According to OSHA, lockout/tagout procedures prevent an estimated 120 fatalities and 50,000 injuries per year. Lockout/tagout tags also help protect equipment from damage or malfunction that could result from improper or incomplete servicing or maintenance. Lockout/tagout tags are essential for workers who perform servicing or maintenance activities on machines or equipment, as well as for other workers who may work in the vicinity of the machines or equipment.

Who Regulates LOTO Tags?

Lockout/tagout tags are part of the lockout/tagout standard that was issued by OSHA in  1989, after more than 12 years of developing requirements based on existing industry standards. The lockout/tagout standard covers the servicing and maintenance of machines and equipment in general industry, and outlines the minimum performance requirements for the control of hazardous energy. The lockout/tagout standard also requires employers to establish and implement an energy control program, which includes written procedures, training, and periodic inspections.

1989, after more than 12 years of developing requirements based on existing industry standards. The lockout/tagout standard covers the servicing and maintenance of machines and equipment in general industry, and outlines the minimum performance requirements for the control of hazardous energy. The lockout/tagout standard also requires employers to establish and implement an energy control program, which includes written procedures, training, and periodic inspections.

Lockout/tagout tags help create a more organized and efficient environment by ensuring that machines or equipment are properly shut down, isolated, and secured before servicing or maintenance work is performed. This reduces the chances of accidents, injuries, or damage that could occur due to the unexpected startup or release of hazardous energy. Lockout/tagout tags also help improve the communication and coordination among workers who are involved in or affected by the servicing or maintenance activities. By providing clear and consistent information about the status of the machines or equipment, lockout/tagout tags help workers avoid confusion, misunderstanding, or conflict that could arise from the lack of awareness or information. Lockout/tagout tags also help enhance the quality and productivity of the servicing or maintenance work, by allowing workers to focus on the task at hand without worrying about the safety or functionality of the machines or equipment.

How do LOTO Tags Relate to Safety?

Lockout/tagout tags are connected with other related concepts, such as machine guarding, electrical safety, and hazard communication. Machine guarding is the use of physical barriers or devices to protect workers from the moving parts of machines or equipment, such as blades, gears, belts, or rollers. Machine guarding helps prevent injuries such as cuts, lacerations, amputations, or crushing. Machine guarding is required by OSHA for machines or equipment that have exposed moving parts that could cause injury to workers. However, machine guarding alone is not enough to protect workers from the hazards of unexpected startup or release of energy during servicing or maintenance activities. Therefore, lockout/tagout procedures are also required to disable the machines or equipment and prevent them from being operated or energized while workers are performing servicing or maintenance.

Electrical Safety

Electrical safety is the prevention of electrical hazards, such as shocks, burns, fires, or explosions, that could result from the contact with or exposure to electricity. Electrical safety involves the proper design, installation, maintenance, and use of electrical equipment, wiring, and circuits, as well as the use of personal protective equipment, such as gloves, boots, or goggles. Electrical safety is regulated by OSHA under the subpart S of the general industry standards, which covers the electrical utilization installations. However, electrical safety does not cover the exposure to electrical hazards from work on, near, or with conductors or equipment in electric power generation, transmission, and distribution installations, which are covered by a separate OSHA standard. Moreover, electrical safety does not cover the exposure to electrical hazards from work on cord and plug connected electrical equipment, which can be controlled by unplugging the equipment from the energy source and keeping the plug under the exclusive control of the worker performing the servicing or maintenance. For other types of electrical equipment, lockout/tagout procedures are required to isolate and de-energize the equipment before servicing or maintenance work is done.

Hazard communication is the process of informing and warning workers about the hazards of the chemicals or substances that they may encounter in the workplace, such as flammable, corrosive, toxic, or reactive materials. Hazard communication involves the use of labels, safety data sheets, signs, symbols, or other means of conveying the identity, properties, and precautions of the chemicals or substances. Hazard communication is required by OSHA under the subpart Z of the general industry standards, which covers the toxic and hazardous substances. However, hazard communication alone is not enough to protect workers from the hazards of the chemicals or substances that may be released or activated by the unexpected startup or release of energy from machines or equipment. Therefore, lockout/tagout procedures are also required to control the hazardous energy sources that could cause the release or activation of the chemicals or substances during servicing or maintenance.

Practical Applications

Lockout/tagout tags have many practical applications and tangible benefits in various industries and sectors, such as manufacturing, mining, construction, healthcare, and education. For example:

- In manufacturing, lockout/tagout tags are used to prevent the accidental startup or release of energy from machines or equipment that produce, process, or assemble various products, such as metal, plastic, wood, or textile. Lockout/tagout tags help protect workers from injuries or fatalities, protect equipment from damage or malfunction, and improve the quality and efficiency of the production process.

- In mining, lockout/tagout tags are used to prevent the accidental startup or release of energy from machines or equipment that extract, transport, or process various minerals, such as coal, iron, gold, or copper. Lockout/tagout tags help protect workers from injuries or fatalities, protect equipment from damage or malfunction, and improve the safety and productivity of the mining operation.

- In construction, lockout/tagout tags are used to prevent the accidental startup or release of energy from machines or equipment that build, repair, or demolish various structures, such as buildings, bridges, or roads. Lockout/tagout tags help protect workers from injuries or fatalities, protect equipment from damage or malfunction, and improve the quality and efficiency of the construction project.

Additional Lockout/Tagout facts:

- According to OSHA, lockout/tagout is one of the most frequently cited standards in general industry, with an average of 2,654 violations per year from 2016 to 2020. The most common types of violations include failure to establish a lockout/tagout program, failure to provide adequate training, failure to use proper lockout/tagout devices, and failure to conduct periodic inspections. Source: https://trdsf.com/blogs/news/everything-about-loto-tags-requirements-and-limitations

- According to the Bureau of Labor Statistics, lockout/tagout can prevent an estimated 120 fatalities and 50,000 injuries each year in the United States. The most common causes of lockout/tagout-related injuries are contact with electrical, mechanical, hydraulic, pneumatic, chemical, or thermal energy sources. The most common types of injuries are burns, cuts, lacerations, amputations, fractures, and electrocutions. Source: http://www.deenergize.com/?target=OSHA_Documentation

- According to the National Safety Council, lockout/tagout is one of the best practices for controlling hazardous energy and reducing the risk of arc flash incidents. Arc flash is a sudden release of electrical energy that can cause severe burns, blindness, hearing loss, or death. Arc flash can occur when workers are performing maintenance or repair work on energized equipment, or when equipment is faulty or damaged. Lockout/Tagout can prevent arc flash by isolating the equipment from the energy source and verifying that it is de-energized. Source: https://www.osha.gov/control-hazardous-energy

- According to the American National Standards Institute (ANSI), lockout/tagout devices should meet certain criteria to ensure their effectiveness and durability. For example, lockout devices should be standardized in color, shape, or size, and should be substantial enough to prevent removal without the use of excessive force or unusual techniques. Tagout devices should be standardized in print and format, and should be legible and understandable by all authorized employees. Source: https://www.assp.org/standards/standards-topics/lockout-tagout-and-alternative-methods-z244-1

- According to a study by the Journal of Occupational and Environmental Hygiene, the use of alternative methods to lockout/tagout, such as warning devices, interlocks, or sensors, can provide equivalent or better protection than lockout/tagout in some situations. The study also found that the use of alternative methods can improve productivity, quality, and reliability, as well as reduce downtime, waste, and costs. However, the study also emphasized that alternative methods should be carefully evaluated and justified before implementation, and should comply with the relevant standards and regulations. Source: https://www.indeed.com/career-advice/career-development/steps-of-lockout-tagout

Similar Questions

- What is a Lockout/Tagout (LOTO) program?

- What is a LOTO procedure?

- What are machine-specific lockout/tagout procedures?

- What is the main goal for a LOTO program?

- What are LOTO devices?

- What is a LOTO station?

- Where should lockout/tagout tags be placed?

- What are some examples of a LOTO procedure?

- What does LOTO stand for?