What are some examples of a LOTO procedure?

Lockout/Tagout (LOTO) procedures are critical safety processes used to ensure machinery and equipment are shut down, isolated from energy sources, and rendered inoperable before maintenance or servicing work begins. The basic steps of a LOTO procedure include notifying affected employees, identifying and isolating energy sources, applying LOTO devices, verifying isolation, and restoring the equipment to service. Here are some examples of LOTO procedures across different situations:

Moving Machine Parts: When maintenance or repair work requires access to areas with moving parts (e.g., robotic arms, welding heads, grinding equipment), there's a risk of being struck, crushed, or caught in the machinery. Therefore, the machine must be completely de-energized and locked out before maintenance or repair work begins.

Fixing Clogged, Damaged, or Missing Parts: Reaching into machinery to clear jams, remove damaged parts, or replace missing components can be hazardous. Any machine with cutting, welding, or crushing actions poses a significant risk. Therefore, applying the LOTO procedure is a must.

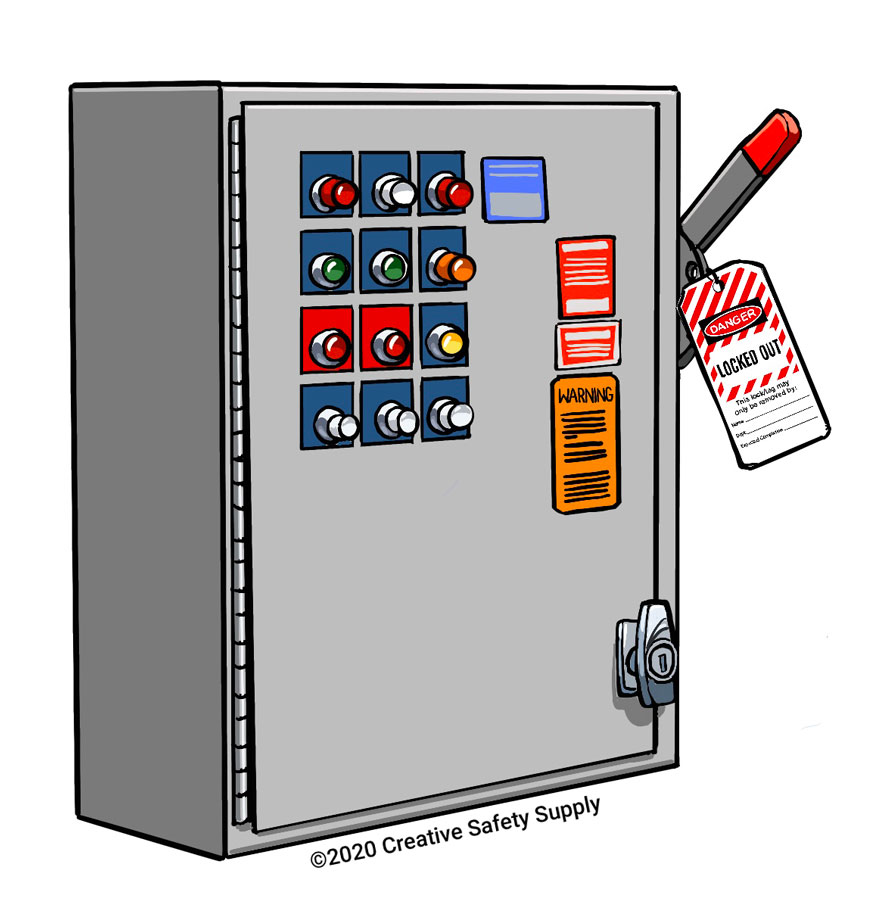

Electrical Work: Lockout/Tagout (LOTO) is crucial for preventing electrical shock or electrocution during work on electrical components. For instance, a padlock and tag are used on a circuit breaker to isolate electrical power.

Scheduled Repairs and Inspections: Any maintenance or inspection requiring access to machinery where stored energy could be released (e.g., mechanical, hydraulic, pneumatic, or electrical energy) necessitates LOTO procedures.

LOTO procedures are crucial for preventing serious injuries and fatalities caused by unexpected equipment startup. Proper training on LOTO procedures is crucial for all employees involved. By adhering to established LOTO protocols, employees can minimize the risk of energy release and the subsequent hazards it can pose.

FAQs

Q: What is the purpose of Lockout/Tagout (LOTO) procedures?

A: The purpose of LOTO procedures is to control the accidental release of hazardous energy that could harm employees. Hazardous energy can be electrical, mechanical, hydraulic, pneumatic, chemical, nuclear, thermal, or gravitational in nature. LOTO procedures involve the complete de-energization of a machine or equipment before servicing or maintenance is performed. LOTO procedures are required by the Occupational Safety and Health Administration (OSHA) in 1910.147(a)(1)(i) for any situation where the unexpected energization or startup of machines or equipment, or release of stored energy, could harm employees.

Q: What are some examples of hazardous energy sources that require LOTO?

A: Some examples of hazardous energy sources that require LOTO are:

- Entering areas with moving machine parts – Robotic arms, welding heads that move around to complete tasks, or grinding equipment are all great examples of moving machine parts that pose a dangerous energy source to maintenance crews.

- Fixing machines that are clogged, damaged, or missing parts – If a part becomes damaged within a machine, it may become necessary for someone to reach in to remove it. Putting your hand into a machine that cuts, welds, or crushes objects has some obvious associated dangers.

- Performing electrical work – Those who work at all with electrical components know that LOTO is necessary for their safety. Scheduled repair and inspections, whether it be in the construction industry or anywhere else, requires energy sources to be contained while necessary work is being done.

Q: What are the benefits of following LOTO protocol?

A: Following LOTO protocol can provide many benefits, such as:

- Improving safety and preventing injuries or fatalities from accidental energization

- Reducing liability and legal risks for employers and employees

- Complying with OSHA standards and regulations

- Enhancing productivity and efficiency by minimizing downtime and errors

- Promoting a culture of safety and awareness in the workplace

Similar Questions

- What is a LOTO procedure?

- What is a Lockout/Tagout (LOTO) program?

- What is the main goal for a LOTO program?

- When should lockout/tagout be used?

- What are machine-specific lockout/tagout procedures?

- What does LOTO stand for?

- What types of hazardous energy can a lockout/tagout program control?

- How does lockout/tagout improve safety?

- Who benefits from LOTO?