Pipe markings are used in a wide range of environments including commercial, industrial, and even residential. They are also used in structures around the world. These markings are an easy and affordable way to ensure those who need to know what is contained within a pipe can identify it right away. In order to make this process easier, most companies have adopted a set of pipe marking standards that was developed by the American Society of Mechanical Engineers, or ASME.

The current set of standards is A13.1, which was updated recently in 2020. These standards cover a variety of different areas related to pipe markings.

Breakdown of Pipe Marking Standards

The ASME standards list a number of different components that need to be included on the labels used for marking pipes. The following are the main areas that are covered under the set of standards from ASME:

- Color Scheme – The color scheme is one of the easiest ways to let people know what is in a pipe. There are quite a few different color standards in place, each with a different meaning. By following the standards, people can look in any facility and quickly identify what types of liquids and gases will be found in each pipe.

- Optional Symbols - Users may use directional arrows as well as GHS pictograms in the event more clarity is needed. However, if choosing to add GHS pictograms, the user must also always include a hazard statement, a signal word, and the name of the substance.

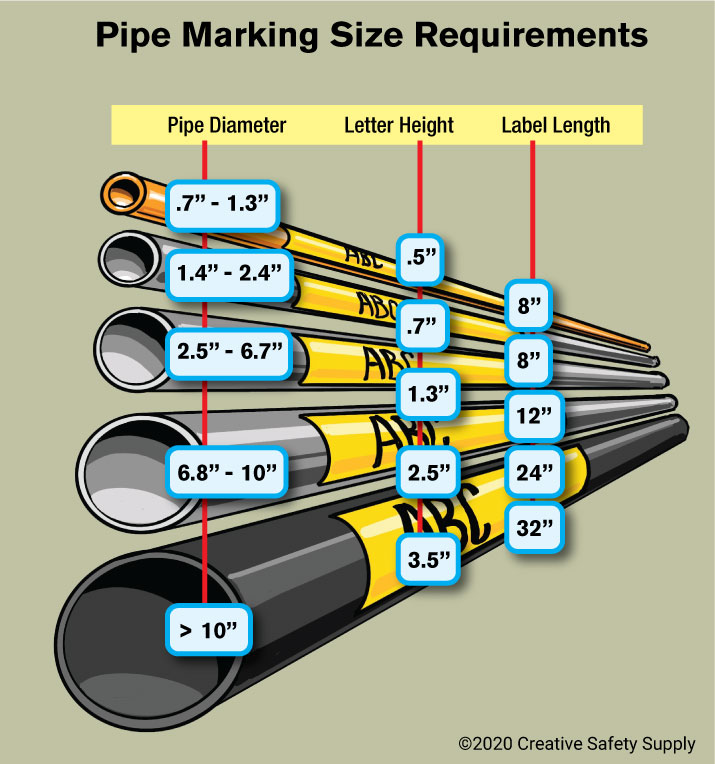

- Label Size – The size of the markings is very important. Pipes themselves vary in size significantly, ASME has several categories of the label length based on how large a pipe is.

- Text Size – Similarly, the size of the text on the markings is important to ensure maximum visibility while still fitting on the labels themselves.

- Label Placement – Pipes often run long distances, and can even travel through walls or other obstructions. ASME has included a list of required placement locations along the pipes to ensure people can easily see what is printed on those labels.

These are the main categories that are covered in the ASME standards. Maintenance workers, emergency responders, and many others will be able to identify a pipe's contents quickly if implemented correctly. This ultimately allows them the ability to make effective decisions while on duty. Even places outside of the United States use these standards, or a local version that is very much like the ASME instructions. This is because they have been proven to ensure the information that is needed is readily available

Similar Questions

- What are the different standards of pipe marking?

- Does OSHA regulate pipe marking?

- What should the height of text on a pipe label be?

- What are the ANSI standards for pipe color codes?

- What is pipe labeling/pipe marking?

- Can I create custom pipe labels and still be compliant?

- Where should I place pipe labels?

- What text should I use on a pipe label?

- Why is pipe labeling important?