Coming up with a good workplace policy to identify where valve tags should be placed is an important part of any safety manager’s job. In most situations there is not going to be a regulatory requirement from a government agency like OSHA specifying where valve tags must be located. There are private organizations, however, that offer best practices to identify where they will do the most good. Taking the time to look through your specific facility and determining where the greatest safety improvements can be made, will help to determine where valve tags should be placed. To do this, it can be helpful to walk through the facility and ask questions about each valve and pipe system.

- What happens if this valve is opened?

One of the most important questions to get the answer to is regarding what happens when a valve is opened. If the valve is used to release a hazardous chemical, it is likely a good idea to have a valve tag in place. If it opens a faucet to water or another safe fluid, it may not be as critical. Of course, there is nothing wrong with tagging safe valves as this will simply provide additional information to those in the area.

- What hazards does the contents of a pipe present?

Knowing what type of hazard will be present when a valve is opened is also important. There is a big difference between opening a valve that could result in a flammable liquid compared to one that releases a corrosive acid. In both cases it is a good idea to use a valve tag to alert people of the potential danger. Using the right type of tag, and including the proper information, will help to ensure the valve tags are as effective as possible.

- Are other forms of visual communication used?

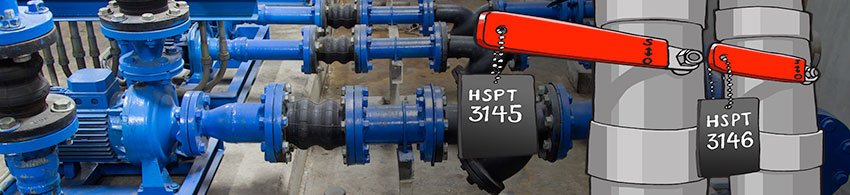

Many pipes will use other pipe markings, which may be sufficient for alerting people to a potential danger. If a pipe is properly marked, it should be easy for people in the facility to gather all the information they need at just a glance. Of course, this doesn’t mean that a valve tag shouldn’t be used, but only that it isn’t quite as necessary. A good valve tag will still provide helpful information about the valve specifically rather than only what is within the pipes.

Creating a custom plan for your facility is well worth the effort. Once in place, a company can follow the valve marking standards for many years to come without any trouble. Any time a new valve is installed, or an old one is replaced, just make sure to add in a new valve tag and update any documentation related to the valves in the facility.

Similar Questions

- When are valve tags used?

- When should I use a pipe tag?

- What are plumbing valve tags?

- How do valve tags improve workplace safety?

- What are the standards and regulations of valve tags?

- What are chemical valve tags?

- Are valve tags the same as pipe labeling?

- How many valves should I tag?

- What are valve tags made out of?