Ammonia Pipe Marking Standards

Because ammonia is harmful to human health—it is corrosive to the eyes, skin, and lungs—any pipes carrying ammonia-based substances must have more specific labeling than those under the ANSI/ASME standards. The International Institute of Ammonia Refrigeration (IIAR) is responsible for setting standards for ammonia and ammonia pipe labeling.

The standards set forth by IIAR requires facilities to label pipes carrying ammonia-based substances with the following information and color-coding:

- Label Body – The body of the label must be orange with “AMMONIA” in black text.

- Physical State – Use either “LIQ” on a yellow background with black text to denote ammonia in a liquid state or use “VAP” on a blue label with black text for ammonia in a vapor state.

- Pressure Level – Pressure must be labeled “LOW” in green with black text or “HIGH” in red with black text. Pressure over 70 psig is considered high pressure whereas pressure equal to or less than 70 psig is considered to be low pressure.

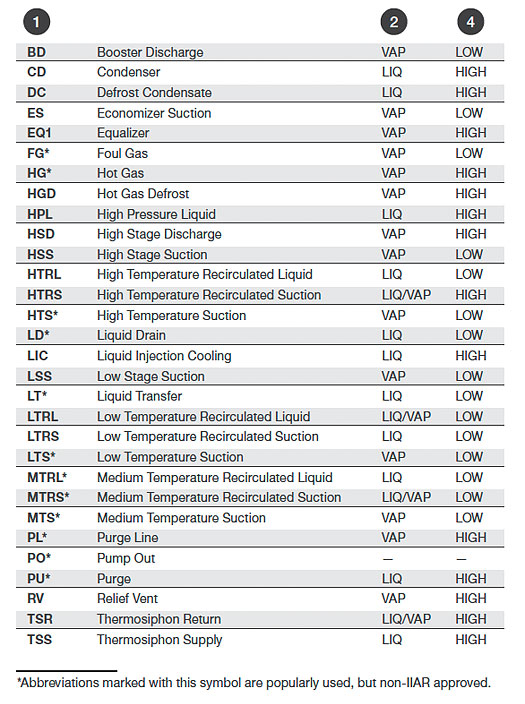

- Abbreviations – Abbreviations can be either an integral part of the ammonia pipe label or be applied separately. The section resides at the very front of the label. The abbreviation is an important piece of information that correlates with the specific purpose of that substance.

- Directional Arrows – These visual components must be black and proportional to the size of the marker.

The chart below lists the common abbreviations for labeling ammonia pipes in accordance with IIAR regulations.

Ammonia is used in a variety of different applications. For example, 87% of the anhydrous ammonia produced is used for crop fertilization, the rest of the 13% is used in various chemical and industrial sectors. Ammonia is also used as cleaning supplies in our homes, as refrigerant, and within plastics production, in explosives, textiles, pesticides, and even dyes. This versatile chemical is necessary for the globe’s way of living, which means the chemical is also mass produced. With that being said, those who handle this chemical need to be safe while doing so, which is why these labeling standards exist.

Maintain Safety with Proper Pipe Marking

Proper ammonia pipe marking is essential for maintaining safety, compliance, and efficiency in facilities that handle ammonia refrigeration systems. Adhering to established standards ensures that employees, contractors, and emergency responders can quickly and accurately identify pipe contents, flow direction, and potential hazards. By implementing clear and standardized pipe markings, businesses not only meet regulatory requirements but also reduce the risk of accidents and improve overall workplace safety. A well-marked ammonia piping system is a crucial component of a safe and efficient operation, reinforcing a proactive approach to hazard communication and risk management.

Similar Articles

- A Guide to Pipe Marking Standards

- Medical Substance Pipe Marking | NFPA99/CGA C-9

- Marine Pipe Marking | ISO/DIS 14726

- Your Guide to Pipe Labeling Standards

- Ammonia Refrigeration

- Water Treatment Pipe Marking

- ANSI Color Codes for Pipe Marking

- Anhydrous Ammonia – Safety & Labeling

- Pipe Color Codes – ANSI/ASME A13.1

- Pipeline Labeling