Resources

Labeling Articles

Safety Protocols for Construction Sites

To ensure the safety and functionality of construction workers, implementation of safety protocols are a requirement that should be exercised in a robust manner. …

Handling Hazardous Materials Safely

A workplace with the involvement of hazardous materials is a high risk ground. Investing in proper safety procedures is a sufficient way to avoid such risks. …

Introduction to Shipping Container Labeling

Shipping container labels convey crucial information throughout the shipping process, contributing significantly to the safety and efficiency of the industry. …

Labeling Practices for Power Generation Facilities

The power generation sector faces distinctive challenges, with hazards ranging from electrocution to arc flashes. Despite these risks, it remains one of the safer sectors due to stringent safety measures and regulations. Power facilities also incorporate redundancies to prevent outages, emphasizing the need for clear communication through labels, signs, and visual tools. …

A Brief Overview of Key Agricultural Labeling Requirements

Whether you operate a commercial farm or you are an employee at a small agricultural facility, it is important that you know all the rules and regulations that you need to follow, including proper labeling. …

A Simple Guide to Transportation Industry Labeling Strategies

Make sure you understand the labeling requirements before shipping any hazardous materials with this simple guide. …

Pharmaceutical Labeling

Learn everything you need to know about pharmaceutical labeling, including the standards it follows, regulatory requirements, and how to create the labels that you need for your company. …

NFPA 855: The Installation of Stationary Energy Storage Systems

NFPA 855 is an essential standard to follow to maintain worker safety while around stationary energy storage systems. …

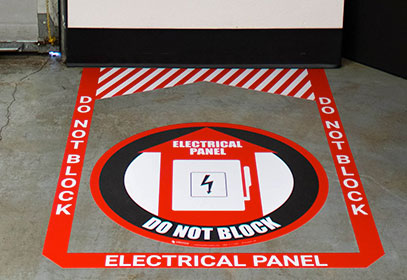

Floor Marking for Electrical Panel Compliance

Meet OSHA requirements for electrical panel clearance with floor markings! Creative Safety Supply offers a wide selection of floor signs and floor tapes for breaker panels. …

Heat Shrink Tubing

Heat shrink tubing and wire markers are excellent visual organization tools. They are cost effective and improve productivity and efficiency within the workplace. …

Keeping Operators Safe with Machine Guarding

Machine guards are essential for facilities where employees work in close proximity to hazardous moving parts. Properly safeguarding machines prevents severe injury and death. …

Creating an Effective Warehouse Storage Numbering System with Barcodes

To streamline operations and prevent waste, warehouses must be organized. An effective warehouse storage numbering system helps workers locate and pick items as quickly as possible. …

Selecting a Marker Size for Wire Marking

An effective wire marking system boosts efficiency and safety in the workplace. This guide helps you determine which marker size is best for the task at hand. …

FOD: How to Control and Prevent Foreign Object Debris

FOD is an acronym for Foreign Object Debris and the consequences caused by this debris, Foreign Object Damage. Controlling FOD is critical in both the aviation and manufacturing industries. …

MIL-STD-129: Military Marking for Shipment and Storage

MIL-STD-129 is the U.S. Department of Defense’s labeling standard for the shipment and storage of military equipment. Contractors must use military shipping labels and adhere to other DOD requirements. …

Rack Labeling

A rack labeling system can vastly improve the efficiency of any warehouse. Barcodes and other rack labels enhance inventory management and allow workers to quickly find items. …

Military Equipment [Condition Tags & Labeling]

Military equipment includes weapons, aircraft, vehicles, and personal gear that was intended for use by the Armed Forces. A wide variety of materials falls under this classification, and proper labeling of their condition is essential. …

Title 49: Shipping Hazardous Materials

CFR 49 notes the procedure for transporting hazardous materials safely in compliance with the HMR. Learn more about this important regulation. …

Food Security

With the 2011 passage of the Food Safety Modernization Act, considerable attention has been focused on the purity of our foods from the perspective of accidental contamination. …

Arc Flash Label Requirements [2018 Updates]

Arc flash hazard labels must be placed on any piece of electrical equipment where workers might need to perform work while the equipment is still energized. …

NFPA 99: Understanding the Health Care Facilities Code

NFPA 99 standards are built specifically to ensure safety from fire danger in healthcare facilities. Learn how to stay in compliance and protect your facility from fire hazards with this overview of the NFPA 99. …

A Quick Guide to Underground Utility Labeling

Underground utility labeling is an essential ingredient to every project that involves construction. This article outlines the step-by-step process of getting your site inspected for utilities, and how to label underground lines safely and accurately. …

Your Guide to Pipe Labeling Standards

If you are looking to implement or update a pipe marking strategy for your facility it is important to gathering as much information as possible. Read More... …

Catchy Safety Slogans for the Workplace

Catchy safety slogan signs are an interesting method that many companies use to keep employees and customers safe. …

Barcode Labeling

Barcode labeling can help improve efficiency and overall accuracy when working with individual items. Learn how barcode labeling can help improve your business today. …

Electrical Wire Colors

Electrical wire colors are essential to the safety of anyone working with electricity. Click here and learn more about electrical color standards. …

OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]

OSHA regulations require businesses to follow one of two safety sign standards to remain in compliance: ANSI 1967 and ANSI 2011. Take a look at these two styles and pick the one that best meets your needs. …

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom. …

NFPA 70E [Workplace Electrical Safety]

NFPA 70E was created to help prevent injuries to workers in energized environments. If you’re working with live energy, you need to know this safety standard to stay OSHA compliant. …

A Guide to Pipe Marking Standards

For most industries, abiding by ASME/ANSI pipe marking standards is sufficient for staying safe and OSHA compliant. Some workplaces, though, are required to comply to more unique pipe marking standards due to the nature of the substance the pipes contain. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

ANSI TIA 606-B Cable Labeling Standards

ANSI TIA 606-B Cable Labeling Standards are a unified labeling method for the wires used in computer systems. These standards help businesses record data and keep their IT environments organized. Get to know these standards; they’ll help your business run more efficiently. …

Waste Water Treatment Labeling

Waste water treatment labeling ensures that all water and flow is accurately labeled. keeping employees safe from contaminated water. …

Lean Healthcare (Principles for Improvement)

Implementing lean healthcare in the medical field will lead to improvement in overall performance and patient satisfaction. …

Arc Flash Labeling (Updated)

Arc Flashes are one of the most dangerous accidents that can happen in a facility. Learn how to keep your facility safe and incident-free through proper labeling. …

Solar System Labeling

In 2017, The National Electrical Code (NEC) made some significant changes to solar system labeling standards. Getting familiar with these updates will help your facility stay safe and efficient. …

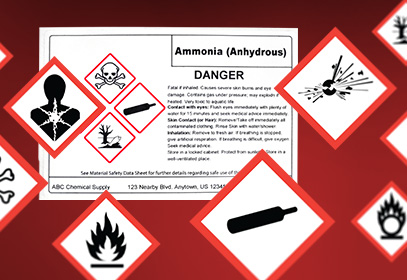

Anhydrous Ammonia – Safety & Labeling

Concentrated (or anhydrous) ammonia presents significant hazards to people and the environment. Here’s what you need to know to stay safe. …

Asset Tags: Tracking Inventory & Equipment

A simple yet powerful organization tool, asset tags reduce theft, enhance inventory management efforts, and make it easier for employees to find exactly what they need exactly when they need it. …

Hazardous Materials Identification System (HMIS Labels)

Having a complete understanding of the Hazardous Materials Identification System (HMIS) is essential to keeping your employees safe when working with chemicals. …

Pipeline Labeling

Pipeline labeling is essential when using pipelines in the facility. Without the proper labeling, you are putting your employees at risk. …

Metal-Detectable Labels for FDA Food Labeling Compliance

Accidental contamination is a major worry in the food industry, and while it’s impossible to completely rule out all contamination, metal detectable labels help eliminate a significant danger. …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Visual Factories

Visual factories use signs, posters, charts, labels and floor marking to provide information that improves efficiency, safety and productivity in the workplace. This is a fairly simple concept that yields excellent results. …

Ammonia Refrigeration

When using ammonia refrigeration, or ammonia for anything in the workplace, there are a variety of OSHA regulations that need to be followed. …

OSHA Safety Sign Requirements [1910.145]

Understanding OSHA standards for warning signs and tags is an essential part creating a safe work environment. …

ANSI Color Codes for Pipe Marking

When following the ANSI A13.1 standards, the most important thing is to understand the six most common color schemes. …

Understanding the NFPA 704 Diamond Labeling System

Learn how to properly label hazardous materials following NFPA 704 labeling standards. …

Labeling Electrical Conduits

Learn how to label electrical conduits so employees can quickly identify them. …

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility. …

Safety Colors (OSHA Guidelines and Color Codes)

Using colors strategically makes communication in your facility more effective. Get the details about common color codes. …

ANSI Z535 [Updated Guide to Safety Signs & Labels]

An in-depth look at ANSI’s standard for safety signs and labels in the workplace. …

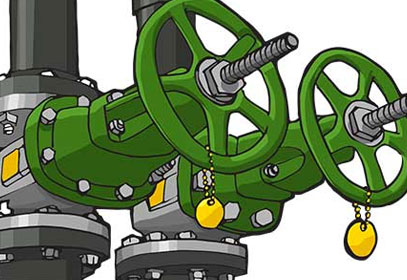

Valve Tags: Guide for Pipe Identification

Tips and recommendations for labeling the valves on your pipe system. …

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know. …

Pipe Color Codes - ANSI/ASME A13.1

The ANSI/ASME A13.1 pipe marking color code explained. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

Cable Management

Properly marking wires can improve organization, facilitate faster maintenance, increase safety, and more. …

GHS Label Creation

Find out how to make Globally Harmonized System (GHS) labels in 3 steps. …

The 5S System [Lean Manufacturing Methodology]

One of the most comprehensive pages you will find on 5S. …

Labeling Questions and Answers

What are the Different Types of Industrial Labels?

The needs and requirements of labels differ across different industries. Serving as important tools that help ensure organization, provide instruction, and enhance safety, ensuring labels are utilized and align with industry regulation is a necessity. In this article, we discuss some different forms of industrial labeling and examples of how they are used. Inventory labeling To maintain… …

How do thermal printers work?

Thermal printers are mostly used in receipt printers and industrial situations. The concept behind this type of printer is relatively simple, but very efficient for the areas where they are used. There are two types of thermal printers, and they work differently. Understanding how they work can help you to pick the right one for… …

What is a direct thermal printer?

Thermal printers are printers that use heat to copy an image onto material. Media (such as paper or synthetics) that has been chemically treated so it’s heat-sensitive passes under the thermal printhead and blackens in order to create an image. These printers are a much more sustainable and user-friendly alternative to traditional laser printing, and… …

How are labels made?

In industrial environments, thermal transfer printers are one of the most commonly used methods of making labels. These printers are able to create high quality labels that withstand light, heat, water, and abrasion, and which can include text, images, and barcodes. Thermal transfer printing is typically the preferred printing method due to its ability to… …

Why is labeling important?

Labeling is essential in any facility no matter the industry, for a wide variety of reasons. From warning of potential hazards to reminding workers to keep their areas clean, labels and other types of visual communication enhance the way your business operates and ensures that people have the information they need to work efficiently and… …

![Military Equipment [Condition Tags & Labeling]](https://www.creativesafetysupply.com/content/images/articles/military-equipment-th.jpg)

![Arc Flash Label Requirements [2018 Updates]](https://www.creativesafetysupply.com/content/images/articles/arc-flash-labels-th.jpg)

![OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]](https://www.creativesafetysupply.com/content/images/articles/ansi-sign-headers-th.jpg)

![NFPA 70E [Workplace Electrical Safety]](https://www.creativesafetysupply.com/content/images/articles/nfpa-70e-th.jpg)

![OSHA Safety Sign Requirements [1910.145]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-warning-signs-tags.jpg)

![ANSI Z535 [Updated Guide to Safety Signs & Labels]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-z535.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)

![The 5S System [Lean Manufacturing Methodology]](https://www.creativesafetysupply.com/template/images/custom/resources-page/Articles-5S.jpg)