Asset tags are used throughout many industries to help keep better track of almost every type of asset. There are many types of asset tags available, and they can contain any type of information the company desires. Understanding how asset tags can benefit a company, and learning how to get the most out of them, is an important area of interest to help with cost savings, waste elimination, and much more.

Benefits of Using Asset Tags

Implementing an asset tag system into a company is a good idea for many reasons. While asset tags are easy to use and very affordable, it is still necessary to look at what types of benefits they can provide in order to justify the effort. The following are some of the most significant benefits of using asset tags in almost every industry.

- Fast Identification - Employees can quickly identify each item using its name, number, or other identifier that is printed on the asset tag. This is especially helpful when working with large numbers of similar systems such as computers, tools, or other assets.

- Easier Inventory Management - Inventory management is a costly and time-consuming effort in almost every industry. Using an asset tag system can help to streamline and even automate the entire effort.

- Audit & Compliance Requirements - In some industries, there are audit requirements or compliance demands from government agencies. Having asset tags can help to remain in compliance so the company can avoid fines or other penalties.

- Insurance Claims - In the event of an accident or disaster, filing insurance claims can be challenging. Companies that have an effective asset tagging system in place are able to more accurately file claims and get the full payout that they are entitled to according to the policy.

- Theft Reduction - Employees or others in the workplace are less likely to steal something when they know the company keeps close track of it. Using asset tags not only reduces the likelihood of something being stolen, but it can also make it easier to find the thief and bring them to justice.

Types of Asset Tags

When starting to use an asset tag system, it is necessary to decide what types of asset tags will work best in a given situation. If possible, using the exact same type of tag for all assets is preferred because it will make the tags more recognizable and easier to find.

In the event that one type of tag won't work on all the assets of a company, it may become necessary to use a variety of different options. Each type has its own advantages and disadvantages to be aware of.

Asset Tag Labels

The most common type of asset tag is going to be the asset tag label. These tags can come in almost any size, and will stick onto an asset with very little effort. Applying a durable asset tag label to any piece of equipment will make it easier to identify. These labels can be printed on most types of industrial label printers so the facility will have the exact tags that are needed when they are required.

Asset Tag Ties

Using asset tags that are attached to zip ties is an excellent option for areas where labels won't work. This could be applied to fans, some types of machinery, vehicles, and much more. These tags are durable as well, which his important for industrial areas.

Asset tag ties can come in many colors, and can have information written on the tag area easily. It is also common for a company to print off an asset tag label, which is then applied to the end of an asset tag tie, which provides the best of both of these two options.

Customer Asset Labels

When a company has assets that are either brought in from a customer, or given out to customers, it may be necessary to track these items. For example, when a reusable container is loaded up with products and sent to a customer, it is best to be able to get those containers back. Having a 'property of COMPANY NAME' sticker on the containers helps to establish ownership of the container.

These types of asset tags will also serve as a reminder to the customer that they need to set the container (or any item) aside to be returned where it came from. This is a form of loss-prevention, and has been shown to be very effective in many industries.

Asset Tracking System

Asset tags are an important part of any effective asset tracking system. These types of systems could be something as simple as keeping track of how many of each item a company owns, or it could use more technical options that are available today.

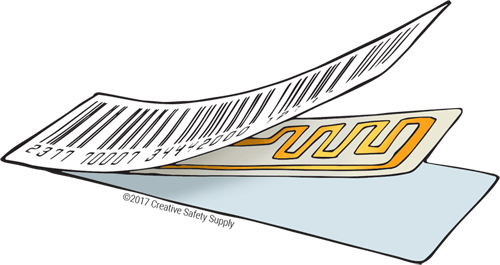

Some asset tags can be printed off with an RFID tag in the label itself. The RFID tag can be tracked within a facility, and even send out an alarm or other notification should it leave a certain area. This is ideal for reducing the risk of loss from theft, and also for finding assets that may have gotten inadvertently misplaced.

Need barcodes?

Our free barcode generator allows you to create custom barcodes readable with any scanner.

Determining the type of asset tracking system a company needs will require some level of research, but whatever decision is made, asset tags play an important role.

Maintaining Asset Tags

As with anything in a workplace, knowing how to properly maintain asset tags is important. Any asset tag label or tie that is made using a good quality label stock will be very durable and can last a long time in almost any environment. Cleaning these types of tags can be done using any normal cleaner.

If there are assets on large assets such as vehicles or machinery, the tag will typically be cleaned at the same time as the asset itself. Asset tag labels can be run through carwashes, sprayed down with cleaning agents, or scrubbed by the maintenance crew. In the event that there is any damage to the tag, they can be reprinted and applied without any issues.

Resources

- https://en.wikipedia.org/wiki/Radio-frequency_identification

- https://community.spiceworks.com/topic/235383-what-is-the-best-asset-tag-practices

Similar Articles

- Perpetual Inventory System

- Barcode Labeling

- Valve Tags: Guide for Pipe Identification

- Labeling Electrical Conduits

- Choosing to Implement a Periodic Inventory System

- 5 Lean Manufacturing Tools that Work

- Warehouse Management (Supply Chain Systems + Visual Management)

- Cross-Docking (Understanding Efficient Warehouses)

- Floor Marking for Factories

- Waste Water Treatment Labeling