Warehouse management inefficiencies can lead to challenges like tied-up capital, increased storage costs, potential financial losses, and even safety hazards. Luckily, rack labeling is a cost-effective and simple way to address these issues by improving accuracy, speeding up order fulfillment, reducing costs, and enhancing safety.

In this article, we will discuss the advantages of using rack labels in a warehouse, outline best practices for implementing rack labeling, and highlight key considerations for barcode labels. We will also look at what other materials you can consider when labeling your warehouse racks.

Benefits to Rack Labeling in a Warehouse

There are a number of reasons to consider implementing a rack labeling system in your warehouse, including:Improved Inventory Control and Accuracy: Clear labels allow for easy tracking of inventory levels and locations, minimizing errors and ensuring accurate stock counts.

Faster Product Retrieval and Reduced Picking Errors: Well-labeled racks enable warehouse staff to quickly locate and retrieve items, reducing picking time and minimizing the risk of selecting the wrong product.

Increased Productivity and Operational Flow: By streamlining the picking and stocking processes, rack labeling contributes to a more efficient workflow and faster order fulfillment.

Cost-Effective Solution: While there's an initial investment, the long-term benefits of reduced errors, faster processing, and improved inventory management lead to significant cost savings.

Enhanced Safety and Clarity: Rack labels can also include safety information, such as weight limits, and help with overall organization, improving the safety and clarity of the warehouse environment.

Best Practices for Warehouse Rack Labeling

While there are no universal requirements or standards to rack labeling, there are a few rules of thumb that will make implementing a rack labeling system easier and ensure that your labels are adapted to your unique needs. If the racks have been split up into smaller sections or bins, remember to designate labeling for each section, not just the entire racking unit itself. Best practices of rack labeling include:- Use a Systematic Labeling Approach: Establish a consistent and logical numbering or naming system for racks, shelves, and locations within the warehouse. This could involve using a combination of letters and numbers to denote aisles, racks, and levels.

- Bottom Up Labeling. Begin labeling from the bottom row of each rack and move upwards. This ensures that the lowest levels, which are often the most difficult to access, are labeled first and that the numbering system remains consistent as you add more levels.

- Select the right labeling materials. In order to save time and money, take into consideration the environment of your warehouse as you choose your labels. Rack labels are available in a variety of materials, and they should match your storage conditions. For example, many industrial freezers have racks and bins, and if you have a freezer, you need cold storage supply labels that are specifically designed for cold environments so they don’t fall off or become illegible. The majority of facilities can invest in traditional vinyl labels, but you may have to look at other options if your warehouse has other needs.

Standardize Placement and Format: Maintain uniform label placement across all racks and shelves to avoid confusion. Use a consistent font size, color, and label material to ensure easy identification.

Ensure Readability and Visibility: Ensure labels are large enough to be easily read from a distance and that the text is clear and high contrast against the background. Avoid placing labels in areas that are obstructed by products or other items.

Pair with Other Signage: Pair your warehouse rack labels with floor and aisle signage to create a cohesive navigation system. This makes it easier for warehouse employees to quickly locate items and navigate the warehouse.

Integrate with WMS: Consider using labeling software that is integrated with your Warehouse Management System (WMS). This can streamline inventory management and reduce errors by ensuring that labels accurately reflect the inventory in each location.

Ensure Long-Term Sustainability: Regularly maintain and update the labeling system to ensure it remains accurate and effective. This includes replacing damaged or faded labels, updating the system to reflect any changes in layout or inventory, and training new employees on the labeling system.

Barcode Features to Keep in Mind

When designing barcode labels for your warehouse racks and shelves, consider:

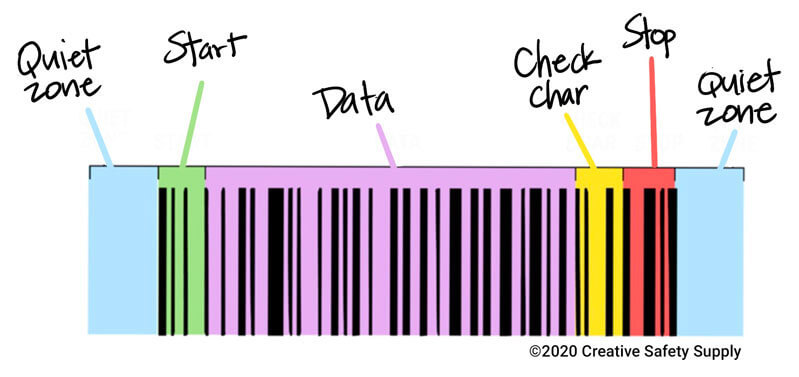

Three important elements of barcodes to consider for rack labeling are:

- Symbology (1D vs 2D): When labeling warehouse racks with barcodes, selecting the appropriate symbology (1D or 2D) is crucial. 1D barcodes, like UPCs, are linear and store limited data, while 2D barcodes, such as QR codes, can hold significantly more information. 2D barcodes are often preferred for their higher data capacity and smaller size, allowing them to store more information in a smaller space.

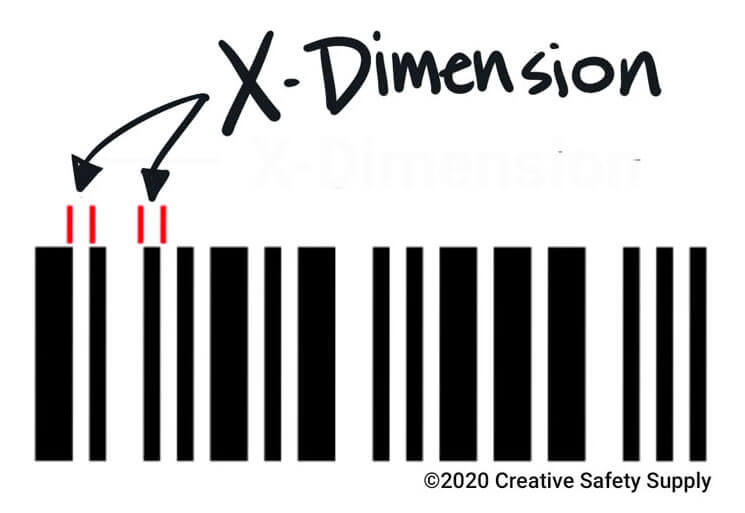

- The X Dimension: The X-dimension refers to the width of the narrowest bar in a 1D barcode. A larger X-dimension makes the barcode easier to scan, especially in challenging environments or with less precise scanning equipment.

- The Quiet Zone. This is the blank space that’s on either end of the barcode. Barcodes cannot go right up to the edge of the label; they need these blank spaces so scanners can get an accurate and complete read. The Quiet Zone also affects the size of your label.

- Color-coding and Visual Cues: Color-coding can enhance navigation and accuracy. Different colors can represent zones, aisles, or rack levels, making it easier for workers to identify locations at a glance.

- Integration with WMS and Scanning Devices: The barcode symbology and format should be compatible with your warehouse's WMS and scanning devices. Testing ensures seamless integration and accurate data capture.

Other Materials Used for Rack Labeling

In addition to barcodes made with traditional vinyl, there are other kinds of supplies that help you organize your racks, such as:- Magnetic Labels. Labels that have a magnetic backing instead of the traditional adhesive are much easier to apply and peel away. With these, you don’t need to worry about leaving a residue behind or having difficulty getting the label off. They’re an excellent choice in situations where you need mobile labels or have a constantly-changing workplace. Warehouses often involve shifting environments, and magnetic labels handle this constant state of flux.

- Cold Storage Labels that stand up to harsh environments such as industrial freezers. These labels can withstand subzero temperatures, and you’ll find other extreme temperature labels such as ones that can survive intense heat. This saves you money in the long run, since these are more durable than traditional labels and you won’t be required to keep replenishing your supply.

- Retro-Reflective Rack Labels, which are a great solution for settings where workers must scan from a distance. By using these labels, you can scan from a range of 50 feet with long-range scanners.

- Totem Rack Labels, which stack barcodes so workers can see items that are located on upper racks. This Totem Pole approach places barcodes on a vertical post where workers can scan them easily, and they are typically color-coded to distinguish between the different rack levels.

- Floor and Aisle Signs. On top of barcodes, investing in a comprehensive visual system can help workers navigate your warehouse. Floor signs aid in locating inventory quickly, while warehouse aisle signs are large and can be seen from a great distance. Together, they enhance your rack labeling system by guiding workers to the correct location of an item.

Rack Labeling for Success

Rack labeling significantly impacts warehouse operations. It is an integral component of successful organizing and forms a cornerstone of lean inventory management. A well‑designed warehouse labeling system reduces waste, improves throughput, enhances safety, and boosts employee morale. When it’s standardized and maintained consistently, it supports both current operations and future growth. With label materials and barcode designs tailored to your environment and aligned with your WMS, you can build a sustainable, efficient warehouse that functions smoothly for years.Similar Articles

- Creating an Effective Warehouse Storage Numbering System with Barcodes

- Labeling Electrical Conduits

- Barcode Labeling

- Arc Flash Labeling (Updated)

- Introduction to Shipping Container Labeling

- Waste Water Treatment Labeling

- ANSI TIA 606-B Cable Labeling Standards

- Solar System Labeling

- Your Guide to Pipe Labeling Standards

- A Brief Overview of Key Agricultural Labeling Requirements