Most of the waste water treatment that takes place in the world is completed by large facilities, often run by local governments. Many other facilities also conduct some type of small scale waste water treatment as well. This may be to treat water that was used for cooling or other things in the facility before it is disposed of.

Regardless of why waste water is being treated, making sure that the process is done safely is very important. One way that this can be done is through the use of waste water treatment labeling. This is a process where the pipes, machines, and other items used throughout the treatment process are labeled correctly so that information can be quickly shared.

Any facility that treats waste water will need to comply with all regulations put in place by both the Environmental Protection Agency (EPA) and the Occupational Health and Safety Administration (OSHA). These agencies have a number of requirements that need to be followed to help protect employees, facilities, the surrounding environment, and anyone who may be exposed to treated water in the future.

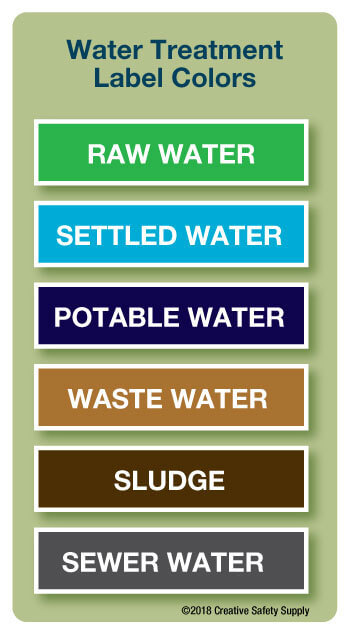

Water Treatment Label Colors

When labeling pipes, storage containers, or other things where waste water is found, the color of the labels is very important. Different types of waste water need to be labeled with a different background color. This makes it possible for employees, emergency workers, inspectors, and others to be able to tell what type of water or other liquid is present.

The following are some of the more common examples of when different colors should be used.

- Raw Water - Raw water should have a label with a green background.

- Settled or Clarified Water - This type of water should have an aqua background.

- Fresh or Potable Water - Potable water should have a dark blue label.

- Backwash Waste Water - Water of this type should have a light brown label.

- Sludge - Sludge will be labeled using dark brown.

- Sewer Water - Dark Grey is used for these labels.

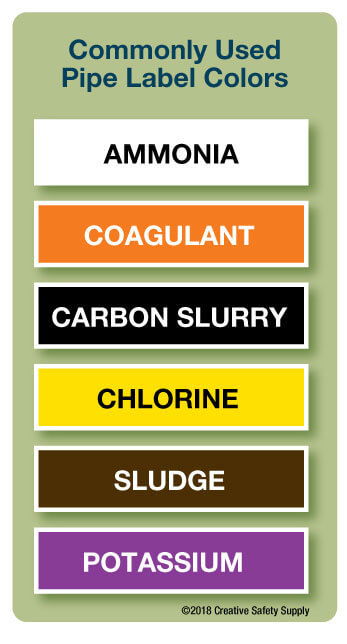

In addition to the labels used to identify what type of water is present, there are also requirements for a variety of chemicals that are commonly found in waste water treatment facilities. The most popular types of labels for these chemicals are as follows:

- Ammonia - Pipes or containers with ammonia in them should have a white label.

- Alum or Coagulant - This type of chemical should be labeled with orange.

- Carbon Slurry - Black labels are used in areas where this is present.

- Chlorine Gas or Solution - Yellow is the color used for pipes containing chlorine gas or a solution with chlorine.

- Potassium Permanganate - This chemical is identified by using violate colored labels.

There are other chemicals that are used in these environments, and many of them will have a specific color or pattern that is used to identify the chemical that is present.

In addition to the color, waste water treatment labels should have written information about what is being labeled. This will begin with large words that say exactly what is in the pipe or container. If there are any warnings or instructions that need to be conveyed, this should be written in smaller lettering under or next to the main wording.

When it comes to labeling pipes, it is important to have arrows that indicate which direction the waste water is flowing within the pipe. This can ben beneficial in many ways including helping with planning any changes, and avoiding problems when trying to shut off the flow in specific areas.

Creating Waste Water Treatment Labels

Most waste water treatment facilities will want to create their own custom labels right at the location where they will be used. This is beneficial because it allows the facility to make custom labels that have the exact information that is needed. It is also helpful because the needed labels can be created on demand so there is no delay when a new one is required.

In most cases, this will be done using industrial label printers. These printers can create labels that are easy to read, contain the exact colors and information that is needed, and are far more affordable than contracting out to a third-party print shop to make the custom labels.

Maintaining Labels

Waste water treatment labels are only useful as long as the people working in the area can see them. If not properly cleaned and cared for, these labels can quickly become unhelpful as dust and other things cause them to be unreadable.

Any surface where these labels are present should be cleaned on a regular basis. Industrial labels such as these can be cleaned using all normal cleaners that would be used on any other surface in the facility. Maintenance teams will typically just have to wipe them down once a week or so to ensure they are always easily visible.

Why Waste Water Labeling is Essential

Many people believe that waste water is simply normal water that has been used for things like cleaning, or other activities, and therefore needs to be treated before it is returned to nature or reused. While this is technically true, there is much more to it than that.

Water is used for many things in many different industries, and waste water can actually be very hazardous. In the battery industry, water becomes contaminated with a variety of chemicals, and can actually cause burns if exposed to the skin. In other industries, it is used to dilute gas and other petroleum products, which can cause the water to have flammable properties.

Removing as much of these contaminants as possible is very important, and doing it in a way that is safe to the people, the facility, and the surrounding environment is required. Having labels in place is an a simple and affordable way to convey information to those who need it, so smart decisions can be made throughout the day. This is just one of the many safety efforts that are made when working with waste water treatment facilities.

Training is Essential

As with all safety programs, it is only good if people understand it and know how to benefit from it. When incorporating labels into a waste water treatment facility, it is important to start by training all the employees, contractors, and others who may come into contact with the labels.

Keeping people informed about why they are there, what the labels mean, and what to do should one become damaged or unreadable will help ensure everyone is able to respond to unexpected situations properly, so everyone can remain as safe as possible while working in and around a waste water treatment facility.

Resources

Similar Articles

- Water Treatment Pipe Marking

- Hazardous Waste Disposal

- Pipeline Labeling

- Anhydrous Ammonia – Safety & Labeling

- Pipe Color Codes – ANSI/ASME A13.1

- ANSI Color Codes for Pipe Marking

- Your Guide to Pipe Labeling Standards

- Solar System Labeling

- ANSI TIA 606-B Cable Labeling Standards

- Understanding the NFPA 704 Diamond Labeling System