The Toyota Production System is known for its pursuit of operational excellence by refining existing procedures and understanding the elements that impede productivity in the workplace. It has achieved the cornerstone of workplace efficiency by abiding to one particular methodology. The 3M concept: Muri (waste), Muda (virability), Muri (overload), is based on the improper distribution of resources in the workplace.

Let’s take a closer look at each element.

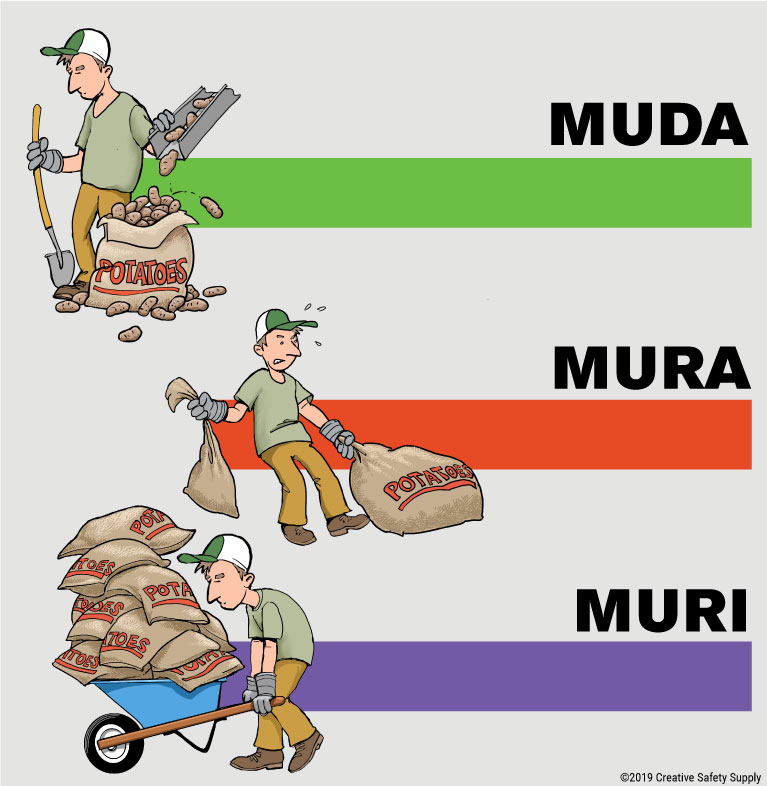

Muri (無理)

Muri means beyond one’s power, overburden, unreasonable, excessiveness, or unrealistic expectations. Employees who are overworked experience greater levels of burnout, and a lack of situational awareness caused by exhaustion can be extremely dangerous, particularly in industries that rely on heavy machinery or hazardous chemicals. Likewise, equipment that’s stressed too much will break down more frequently and can create wholly new hazards for anyone nearby.

Muri could and should be avoided with the establishment of standardized work. Ensuring that all employees know how to complete a task one way is the definition of standardization. In a facility without a standardized workflow, there could be 10 different ways a manufacturing process is completed just because of a lack of communication not only between departments but also between he employees and management themselves.

A proper system of workplace communication and task allocation can help avoid Muri and its adverse effects by evenly distributing the workload and not having an employee or machine shoulder the workload alone.

Mura (斑)

Mura loosely translates to unevenness, non-uniformity, and irregularity. This loosely translates to lack of symmetry, where one step in a process is not aligned with the remaining ones, leading to bottlenecks or lead time. For instance, in a warehouse, the capacity of the inventory to store raw materials is larger compared to the inventory reserved for the finished product. This irregualrity can lead to accumulation of waste in the form of overproduction, wastes, etc.

In other words, Mura is a key driver which ultimately leads to Muda. This can be effectively avoided by designing a system, where each step or phase of the process is directly intertwined with the other to ensure consistency.

Devising a way to prevent Mura in the workplace could begin with establishing a Just-in-Time production system. Keeping little to no inventory in storage establishes a pull system from the manufacturing process. This means the right parts must be delivered or made at the right time to produce an even workflow for employees while also decreasing the cost of inventory storage, preventing bottlenecks, and increasing efficiency.

To get here, companies may choose to implement Kanban to establish that “pull” effect in the manufacturing process. Heijunka is also an excellent production leveling tactic.

Muda (無駄)

Muda translates to wastefulness, uselessness, and futility. It pertains to activities or processes that do not add value to the final product. There are two types of Muda.

Type 1: The first type includes activities that are essential to maintain the value of the product throughout its delivery. This includes activities like inspection and safety testing, which do not offer value to the customer but are an integral part of the process.

Type 2: The second type includes non-value added activities which do not serve any gain or profit to the end result. These activities typically include the TIMWOOD wastes, such as:

- Defects occurring in the final product

- Waiting for the next step in production to occur

- Excess motion of people and equipment than is needed

- Excess inventory that is sitting and taking up space

- Overproduction, meaning that the manufacturing process is ahead of public demand

- Overprocessing without creating value

- Unnecessary transport or handling of materials

The latter form of Muda is what contributes to the above wastes as well as any hidden costs within the process. This is the form of waste that must be eliminated.

Similar Glossary Terms

- 7 Wastes of Manufacturing

- Understanding Lean Manufacturing Terms

- Heijun-ka

- TIMWOOD

- Waste of Overproduction

- Lean Production

- DOWNTIME

- Lead Time

- Capability