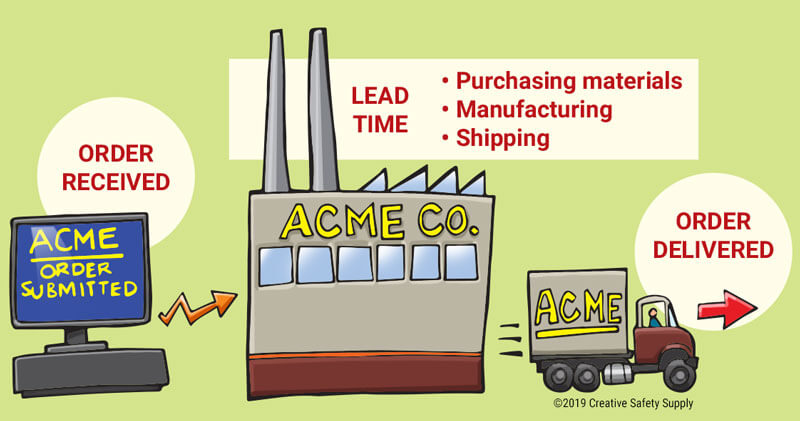

Lead time is the amount of time it takes from the moment a customer places an order to the moment the product is out for a delivery. This includes any time taken to manufacture materials for the finished product or the time it takes to receive the materials.

All activities, wasteful or not, add up to the lead time. Consequently, it's beneficial to reduce waste by implementing Lean strategies. For instance, utilizing the Kanban system will alert the appropriate time to replenish supplies before it runs out, effectively reducing lead time. When the lead time for a product is short, the company that makes it can hold fewer finished goods to fulfill orders, effectively reducing the waste of excess inventory.

Understanding and knowing a facility’s lead time is extremely important to workplaces using Just-in-Time manufacturing or practicing Lean manufacturing as the two are closely intertwined. Lead time can be utilized alongside other Lean tools, like value stream mapping. During mapping, one can count the inventory at each step of the operation and work with the Lean team to identify areas that are wasteful and could be streamlined to reduce waiting and an overflow of inventory.

Excess inventory is waste, presents quality issues, takes up extra storage, and costs more money; reducing inventory on hand will decrease lead time. On the flip side, high levels of inventory will lead to longer lead times. Managers should know and understand the status of inventory levels, while being mindful of cost and the replenishment lead time.

Consider this lead time example:

If Company X receives an order from Customer Y for Product Z every 3 days, but lead time for that product is 5 days, the company will need to have extra inventory on hand to fill those orders. If the lead time is shortened to 3 days, however, the company no longer needs to hold that extra inventory to meet customer demand because production can keep pace with customer orders.

Lead Time vs. Cycle Time

The terms ‘lead time’ and ‘cycle time’ are often used interchangeable, but they are two different calculations. Where the former measures the time from order to delivery, cycle time measures the time it takes to complete production, from start to finish, of a single unit. Lead time is more customer focused, measuring the arrival rate, and cycle time measures the actual rate of work. Cycle time directly affects lead time, meaning companies can noticeably reduce their lead time by more effectively managing their cycle time.

Similar Glossary Terms

- Cycle Time

- Takt Time

- Just-in-Time Production

- Material Flow

- DOWNTIME

- Waste of Overproduction

- Inventory Management

- Idle Time

- Pull System