Pipe Color Code Standards

Pipes are used in facilities to transport liquids and gasses from one place to another, both short and long distances. Most facilities have dozens of pipes moving substances from place to place and because of this, it is important to be able to keep track of the contents in each pipe as well as its destination.

Following pipe color-coding is extremely helpful for obtaining crucial information about a pipe’s contents. If color codes are ignored, employees are at a higher risk of causing an accident that may result in physical harm as well as facility damage. For example, if a worker opens a pipe that is not identified correctly, he or she may expect clean water but instead, open a valve to find toxic chemicals.

ANSI/ASME A13.1 Pipe Marking Standard

Pipe color-coding is not a complicated process, especially if industry standards are used. There are many standards out there from a variety of sources, but by far the most popular is the ANSI/ASME A13.1 standard. This standard explains colors, text, size, and placement of pipe marking labels.

Following this type of color-coding standard makes it easy to offer training to employees and also helps ensure different departments within a facility are all using the same colors for their pipes. Not only that, but ANSI is such a well-respected and trusted organization that its voluntary standards are applied by numerous industries without hesitation.

Colors, Words, and Symbols

- Words - Writing out the contents of the pipe is important. These words should be easy to read, so choose a simple font.

- Symbols - Most pipe markings will also feature a symbol. In the United States, this is usually an arrow that points in the direction the pipe contents flow. A label can also have common warning symbols to alert people to potential dangers; this is common in Europe.

When using pipe markings, a facility must choose to either buy generic pipe markings, special order custom pipe markings or obtain blank pipe markings that can be printed using an industrial label printer. Each of these options can be effective, but for facilities with a large quantity of pipes and valves, a label maker is going to be the ideal option. On the other hand, for those who need just a few labels, special ordering is likely the best choice.

ANSI/ASME A13.1 Pipe Color Code Standards Explained

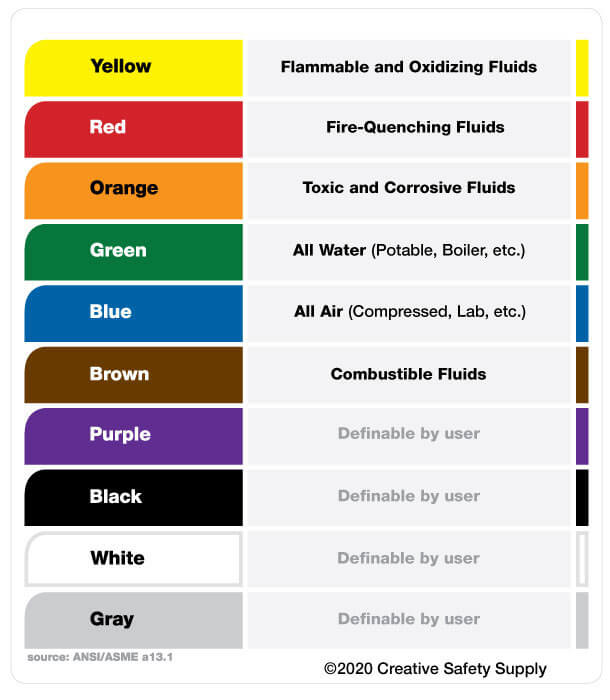

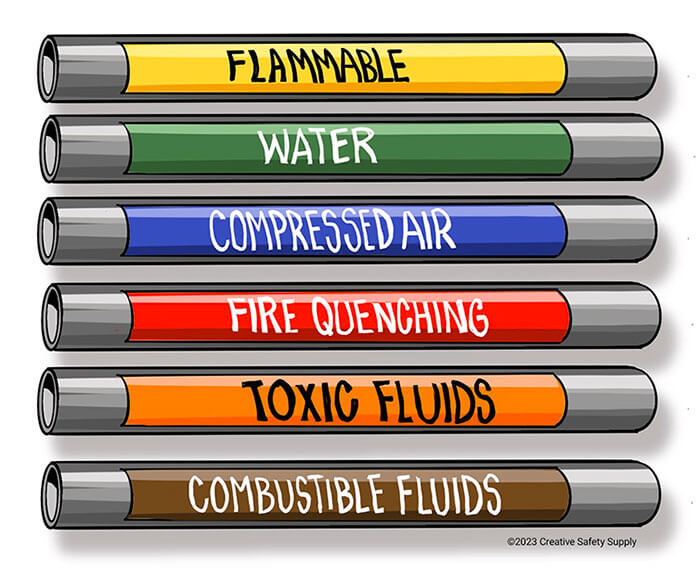

Businesses should familiarize themselves with the ANSI/ASME A13.1 pipe color code standard, which is the industry consensus standard for marking pipes. This standard identifies the color of the labels and what those colors mean. The following are the main options for this set of standards:

- Yellow with Black Lettering - This option is used for any pipe that contains flammable and oxidizing liquids and gasses. This could include gasoline, oils, and many others.

- Green with White Lettering - Using a green label with white lettering means that the pipe contains potable water. It could be used for cooling, feeding boilers, or even going to drinking fountains or sinks.

- Blue with White Lettering - Blue labels with white lettering are used for pipes that transport compressed air.

- Red with White Lettering - Red labels with white lettering are used for all fire-quenching fluids. This could include water, but only if the pipe is used just for fire quenching.

- Orange with Black Lettering - Orange labels with black lettering are for toxic, poisonous, or corrosive fluids. Most acids will need to use this type of pipe marking.

- Brown with White Lettering - This option is for all combustible fluids.

The ANSI/ASME color codes for pipes also leave several color combinations for "user-defined" pipes. These color combinations allow facilities to plan out certain pipes that don't fit in with the normal standards. It is important to remember, however, that when using user-defined pipe markings, these labels may confuse everyone who has not been sufficiently trained.

The user-defined color options are:

- Purple with White Lettering

- White with Black Lettering

- Gray with White Lettering

- Black with White Lettering

Pipe Marking Size Requirements

The color of pipe markings is typically the most important and visible aspect of the label, but it is not the only one. ANSI also has standards regarding how large a pipe marking label should be and the letter height on the label. This is especially important when creating a custom labels for a facility. The standards for sizing are as follows:

| Pipe Diameter | Pipe Marking Size |

| 0.7" - 1.3" (18-33mm) | should have labels that are at least 8" (200mm) in length and lettering that is at least™ in 0.5" (13mm) in height |

| 1.4" - 2.4" (34-61mm) | should have labels that are at least 8" (200mm) in length and lettering that is at least 0.7" (19mm) in height |

| 2.5" - 6.7" (62-170mm) | should have labels that are at least 12" (300mm) in length with lettering that is at least 1.3" (32mm) in height |

| 6.8" - 10" (171-254mm) | should have labels that are at least 24" (600mm) in length with lettering that is at least 2.5" (64mm) in height |

| greater than 10" (254mm) | should have labels that are at least 32" (800mm) in length with lettering that is at least 3.5" (89mm) in height |

These standards are important because they will help ensure that the pipe markings are as visible as possible, even from a distance.

Ammonia Refrigeration Pipe Marking Standards

A set of standards developed specifically for ammonia pipes exists as well. These standards were published by the International Institute for Ammonia Refrigeration (IIAR) and are typically used wherever ammonia is present. The IIAR standard can be used along with other standards if necessary. The ammonia-specific requirements are important because this chemical can be quite dangerous and is used in many industries.

Marine Pipe Marking Standards

There is also a set of standards created by the International Organization for Standardization (ISO) for pipe marking in marine environments. The standards put out by this organization have similarities to ANSI standards, but in many cases have more specific instructions and color combinations with special banding. The ISO 14726 standard applies to sea vessels and other marine workplaces.

Using Pipe Color Code Charts

One of the most effective ways to make sure people in the facility always know what each color label means is to hang up pipe color code charts. These are effective because employees can reference them before taking any action. This is especially important for employees who don't often need to access the facilities piping system and may not remember the color code in detail.

Color code charts can come as posters, pocket handouts, binders, or other forms depending on a facility's requirements. This type of chart can be used as part of a training class and then distributed for regular reference as needed.

Creating Custom Labels for Pipe Marking

Most facilities will prefer having the option to create custom labels themselves instead of ordering them from a third-party printer. If a facility has a good quality industrial label printer, this can be easy and economical. In fact, choosing to print labels in-house will allow for the user to save on more than half of costs and the bonus of not having to put a pipe labeling project on hold while waiting for the labels to arrive.

Not sure which pipe labels you need?

The pipe label calculator helps you choose the right labels for your pipes.

However, it is very important to remember that following the set facility color standards when designing a custom label is critical. Choose the same shades of colors that ANSI specifies so colors are consistent.

See how simple it can be to design, print, and apply pipe marking labels with this video:

Caring for Pipe Labels

No matter where a facility gets its pipe marking labels, it is important they are properly cared for once they are placed on the pipes. In industrial settings, pipe markings can get covered in dust, grease, and other contaminants over time, especially if pipes are located in out-of-reach areas such as near the ceiling.

Cleaning pipes on a regular basis will make labels easy to see. Even having a layer of dust on a label can cause the color to appear different than it is. This could cause someone to incorrectly assume they know what is in a given pipe, which opens them and the facility up to the potential for dangerous accidents.

Fortunately, pipe marking labels are typically made to stand up to any cleaning, so they will last for a long time with proper care. When facilities take the time to dust or wash the pipe markings at least a few times per year, it is easy to avoid any harmful problems associated with dirty labels.

Ensuring Pipe Colors are Visible

The following considerations will help ensure pipe labels are visible to the people who need to see them:

- The Frequency of Labels - Labels need to be placed at least every 25-50' on the pipe so they are easy to see. It is also important to add a label if the pipe changes direction so that it is clearly visible.

- Obstructions to the Label - If a pipe goes through a wall or around a corner, labels should be placed on either side so that people can see the color of the label from any angle.

- Lighting - While pipes are often in areas that don't get too much light such as under the floors or in the rafters, it is helpful to ensure a sufficient amount of light is reaching them so people can see the colors and words on the labels.

- Near Access Points - If there are designated access points to a pipe, it is important to have a label visible. This will help the maintenance team quickly determine what is in a pipe before working on it.

- Near End Points - At either end of the pipe, there should be a label so that people using the pipes can quickly see what is in them.

Similar Articles

- ANSI Color Codes for Pipe Marking

- Safety Colors (OSHA Guidelines and Color Codes)

- A Guide to Pipe Marking Standards

- Pipeline Labeling

- Your Guide to Pipe Labeling Standards

- Electrical Wiring (Wire Color Codes)

- Ammonia Pipe Marking Standards | IIAR Requirements

- Valve Tags: Guide for Pipe Identification

- Marine Pipe Marking | ISO/DIS 14726

- ANSI TIA 606-B Cable Labeling Standards