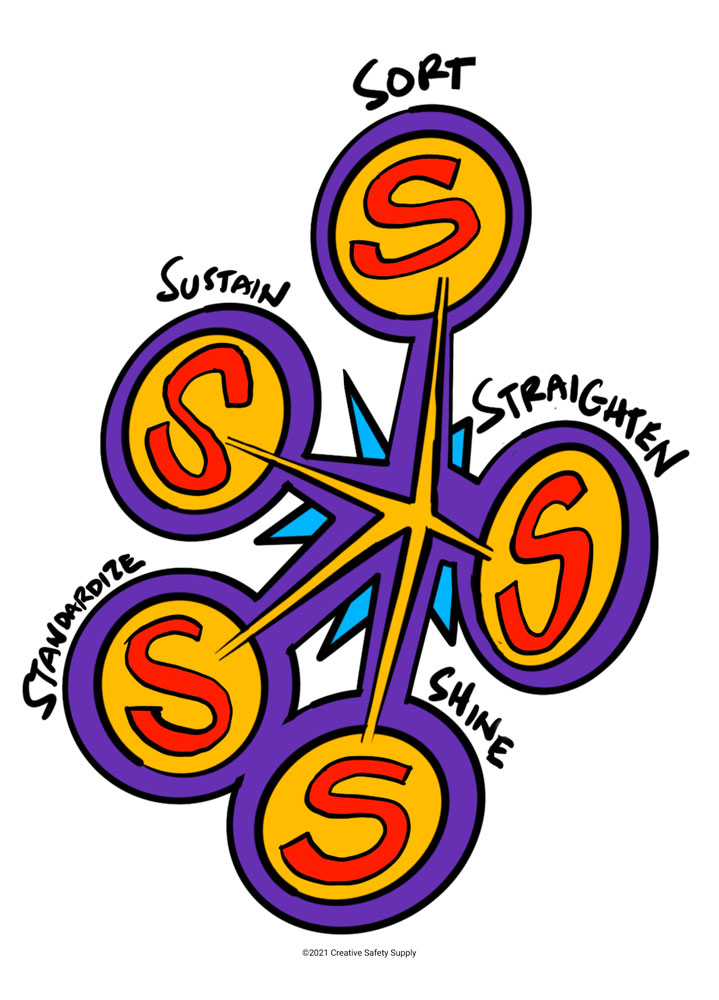

When looking at the 5S methodology, it is clear that it is a great way to identify and eliminate various types of waste in the workplace. When done properly, 5S can also help to improve the overall safety in the facility. In fact, it has been shown to be so effective at improving safety that many places have begun calling it 6S, with the sixth S standing for safety.

Each S Helps with Safety

Even without incorporating a sixth S, it isn’t difficult to see how 5S can help a company improve safety. Looking at each of the main ‘S’s” it is easy to see how a facility will become safer when properly implemented.

- Sort – Sorting an area out, removing any clutter, and ensuring the only items in an area are those that are strictly needed will eliminate obstacles. There are less items to run into, trip over, catch on fire, or cause other types of damage. A well-sorted workplace is a safer workplace.

- Straighten – Everything in a facility should have a set place where it is kept. When things are in their proper place, it is less likely that an employee will grab the wrong item. Using wrong items can cause serious risks to the safety of the facility, which is why a facility that is properly straightened up is a safer facility.

- Shine – Keeping a company clean and well-maintained is very important for safety. Wiping away dust, for example, removes a fire hazard. Cleaning up spills reduces the risk of slip-and-fall accidents. There is really no doubt that a company that is properly shined is a company that is safer.

- Standardize – Standardizing processes will ensure everything is done the same way every time. This will reduce the risk of malfunctions, accidents, and other issues. Environments that follow standard processes are going to be safer environments.

- Sustain – Of course, it is important to sustain all the effort that is made in the previous steps. Taking action on any of the other S’s once won’t do much good, but sustaining it over time will be very helpful. In fact, the longer the 5S methodology is followed, the safer the facility will be. With this in mind it is clear that a company that has sustained effort will be much safer.

Whether a company is primarily looking to eliminate waste, improve productivity, increase the bottom line, or become a safer workplace, 5S is an excellent strategy to use. It has been around for years, and proven effective by thousands of companies around the world.

Frequently Asked Questions

Q: What is 5S methodology?

A: 5S methodology is a system for organizing and maintaining a workplace that aims to eliminate waste, improve productivity, and enhance safety. The name 5S comes from the five Japanese words that describe the steps of the process: seiri (sort), seiton (straighten), seiso (shine), seiketsu (standardize), and shitsuke (sustain).

Q: What is the difference between 5S and 6S?

A: Some companies have added a sixth S to the 5S methodology, which stands for safety. This emphasizes the importance of creating a safe work environment by following the other five S’s. However, even without adding a sixth S, 5S can help to improve safety by reducing clutter, ensuring proper placement of tools and equipment, keeping the workplace clean and well-maintained, following standard procedures, and sustaining the improvements over time.

Q: How does each S help with safety?

A: Each S helps with safety in different ways:

- Sort: Sorting an area out, removing any clutter, and ensuring the only items in an area are those that are strictly needed will eliminate obstacles. There are less items to run into, trip over, catch on fire, or cause other types of damage.

- Straighten: Everything in a facility should have a set place where it is kept. When things are in their proper place, it is less likely that an employee will grab the wrong item. Using wrong items can cause serious risks to the safety of the facility.

- Shine: Keeping a company clean and well-maintained is very important for safety. Wiping away dust, for example, removes a fire hazard. Cleaning up spills reduces the risk of slip-and-fall accidents.

- Standardize: Standardizing processes will ensure everything is done the same way every time. This will reduce the risk of malfunctions, accidents, and other issues.

- Sustain: Of course, it is important to sustain all the effort that is made in the previous steps. Taking action on any of the other S’s once won’t do much good, but sustaining it over time will be very helpful. In fact, the longer the 5S methodology is followed, the safer the facility will be.

Similar Questions

- How does 5S increase workspace productivity?

- What is the 5S methodology?

- What are some examples of 5S strategies?

- What is the difference between 5S and 6S?

- How does 5S help achieve Lean Manufacturing excellence?

- What are the principles of 5S?

- What are the 5 S’s and what do they stand for?

- Who should implement 5S?

- What is the meaning of 5S? A Workplace Organization and Efficiency Guide