What does TPM stand for? This is a common question that many people may have when they encounter this acronym in different contexts. In this article, we will explore the meaning, history, and benefits of TPM, as well as its relation to other concepts such as lean manufacturing, total quality management, and trusted computing.

The Origins of TPM

TPM stands for Total Productive Maintenance, a method of physical asset management that aims to improve the efficiency, quality, and safety of manufacturing processes by involving all employees in the maintenance and improvement of equipment. TPM was developed in Japan in the 1950s and 1970s by Seiichi Nakajima, who is considered the father of TPM. He integrated the best practices of preventive and predictive maintenance, as well as employee involvement and continuous improvement, into one systematic approach. TPM was first applied in Nippondenso, a supplier of Toyota, and later became widely adopted by many Japanese and global companies. TPM is also recognized as an international standard by the ISO/IEC 11889.

Core principles of TPM

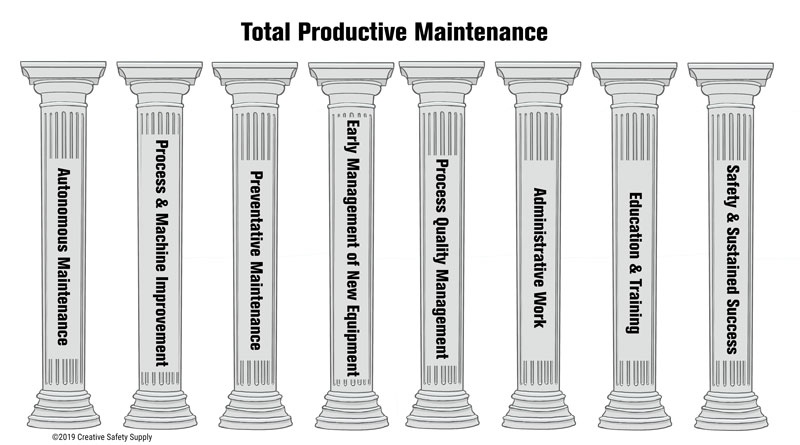

TPM has eight pillars or activities that support its implementation and goals. These are:

- Autonomous Maintenance: Autonomous Maintenance involves training and empowering operators to perform basic maintenance tasks on their own equipment, such as cleaning, lubricating, inspecting, and adjusting. This helps to prevent breakdowns, defects, and accidents, as well as to improve the operators’ skills and morale.

- Focused Improvement: This involves forming cross-functional teams to identify and solve chronic or major problems that affect the performance of equipment and processes. This helps to eliminate waste, reduce costs, and increase productivity and quality.

- Planned Maintenance: Planned Maintenance involves scheduling and performing regular maintenance activities on equipment, such as repairs, replacements, overhauls, and inspections. This helps to optimize the availability and reliability of equipment, as well as to reduce downtime and maintenance costs.

- Quality Maintenance: Quality Maintenance involves preventing and eliminating defects and errors in products and processes by using tools and techniques such as statistical process control, mistake-proofing, and root cause analysis. This helps to ensure customer satisfaction and loyalty, as well as to reduce rework and scrap costs.

- Early Equipment Management: This involves designing and installing new equipment that is easy to operate, maintain, and improve, as well as involving operators and maintenance staff in the selection and commissioning of new equipment. This helps to reduce the lifecycle costs of equipment, as well as to enhance its performance and quality.

- Training and Education: This involves developing and delivering training and education programs for all employees to improve their knowledge, skills, and abilities related to TPM. This helps to create a culture of learning and improvement, as well as to increase the motivation and engagement of employees.

- Office TPM: Office TPM involves applying the principles and practices of TPM to the administrative and support functions of an organization, such as accounting, purchasing, human resources, and information technology. This helps to improve the efficiency and effectiveness of these functions, as well as to support the production processes and customer service.

- Safety, Health, and Environment: This involves ensuring the safety, health, and well-being of all employees, as well as minimizing the environmental impact of the organization’s activities. This helps to comply with legal and ethical standards, as well as to enhance the reputation and social responsibility of the organization.

Key TPM Metrics

The benefits of TPM are manifold and can be measured by various indicators, such as:

- Overall Equipment Effectiveness (OEE): This is a metric that combines the availability, performance, and quality of equipment and processes. TPM aims to increase the OEE by reducing losses and waste, such as breakdowns, setup times, speed losses, defects, and rework.

- Mean Time Between Failures (MTBF): This is a metric that measures the average time that a piece of equipment operates without failure. TPM aims to increase the MTBF by preventing and eliminating the causes of failure, such as wear and tear, misalignment, contamination, and corrosion.

- Mean Time To Repair (MTTR): This is a metric that measures the average time that it takes to repair a piece of equipment after a failure. TPM aims to reduce the MTTR by improving the maintenance skills and tools, as well as by simplifying the repair procedures and parts.

- Customer Satisfaction: This is a metric that measures the degree to which customers are satisfied with the products and services of an organization. TPM aims to increase customer satisfaction by delivering products and services that meet or exceed the customer’s expectations, as well as by responding to customer feedback and complaints.

- Employee Satisfaction: This is a metric that measures the degree to which employees are satisfied with their work and workplace. TPM aims to increase employee satisfaction by providing a safe, clean, and comfortable work environment, as well as by involving employees in decision making and improvement activities.

TPM in Various Industries

TPM is closely related to other concepts that share similar goals and principles, such as:

- Lean Manufacturing: This is a philosophy and methodology that focuses on eliminating waste and maximizing value in production processes. TPM supports lean manufacturing by reducing the waste of defects, overproduction, waiting, transportation, inventory, motion, and processing, as well as by increasing the value of quality, speed, flexibility, and customer service.

- Total Quality Management (TQM): This is a philosophy and methodology that focuses on achieving customer satisfaction and continuous improvement in quality. TPM supports TQM by preventing and eliminating defects and errors in products and processes, as well as by involving all employees in quality improvement activities.

- Trusted Computing: This is a technology and concept that focuses on enhancing the security and privacy of computer systems and networks. TPM supports trusted computing by providing a hardware-based, secure cryptoprocessor that can generate, store, and limit the use of cryptographic keys, as well as by ensuring the integrity of the system’s boot process and software.

In conclusion, TPM stands for Total Productive Maintenance, a method of physical asset management that aims to improve the efficiency, quality, and safety of manufacturing processes by involving all employees in the maintenance and improvement of equipment. TPM has eight pillars or activities that support its implementation and goals, and it offers various benefits that can be measured by different indicators. TPM is also related to other concepts that share similar goals and principles, such as lean manufacturing, total quality management, and trusted computing. By applying TPM, an organization can achieve a more organized and efficient environment, as well as a competitive advantage in the market.

Additional TPM facts:

- According to a study by the Japan Institute of Plant Maintenance (JIPM), the average improvement rate of OEE (Overall Equipment Effectiveness) after implementing TPM was 59%, and the average reduction rate of breakdown losses was 88%. The study also found that TPM had positive effects on other performance indicators, such as productivity, quality, delivery, cost, safety, and morale. Source: https://www.dynaway.com/blog/the-total-productive-maintenance-tpm

- According to a survey by the Aberdeen Group, the best-in-class manufacturers that adopted TPM achieved an average OEE of 90%, compared to 76% for the industry average and 66% for the laggards. The survey also revealed that the best-in-class manufacturers had 3 times lower unscheduled downtime, 4 times lower injury rate, and 26% higher profit margin than the laggards. Source: https://website.maintenanceconnection.com/resources/blog-posts/improving-manufacturing-overall-equipment-effectiveness-oee-cmms

- According to a report by the World Class Manufacturing Association (WCMA), the top three benefits of TPM reported by the member companies were improved equipment reliability, improved product quality, and improved employee involvement. The report also identified the top three challenges of TPM implementation as changing the organizational culture, sustaining the improvement activities, and measuring the results. Source: https://world-class-manufacturing.com/tpm/

- According to a case study by the International Journal of Engineering Research and Technology (IJERT), the implementation of TPM in a textile industry resulted in a significant improvement in the performance of the spinning machines, such as reducing the breakdown time by 71%, reducing the defects by 62%, and increasing the production by 27%. The case study also estimated that the annual savings due to TPM implementation were around 2.5 million Indian rupees. Source: https://www.ijert.org/

- According to a research paper by the International Journal of Scientific and Research Publications (IJSRP), the implementation of TPM in a cement industry led to a remarkable improvement in the performance of the kiln and the cement mill, such as increasing the availability by 11%, reducing the downtime by 74%, and reducing the energy consumption by 8%. The research paper also calculated that the annual savings due to TPM implementation were around 51.8 million Nigerian naira. Source: https://www.ijsrp.org/

Similar Questions

- How are TPM and Lean related?

- Who developed TPM?

- What are the pillars of TPM?

- What is the difference between TPM and TQM?

- What are some tools of TPM?

- How does TPM relate to OEE?

- What are the steps to implementing TPM?

- How can I use visual communication in TPM?

- What are the objectives of TPM?