Total productive maintenance and total quality management are two terms often used interchangeably when talking about Lean manufacturing. While the two programs do share a number of similarities, they are in fact two different approaches.

Although both Lean, both terms have important distinctions. In fact, both methods should be used to achieve maximum efficiency in your facility. TQM, or total quality management, is a management philosophy based on quality control, whereas total productive maintenance, or TPM, is a concept focused on improving maintenance processes through predictive and preventative maintenance. TQM seeks to systemize management and align divisions in an organization to improve the quality of a product and reduce the number of defects. TPM on the other hand, works to improve efficiency by involving equipment operators in the ongoing maintenance of the machines they use.

TPM’s objectives are based on the belief that small consistent improvements have a larger, more impactful influence than making huge, sweep changes every once and awhile. TQM is focused more on customer needs, expectations, and satisfaction. This concept uses strategy, data, and effective communication to ensure discipline and best practices in production so that quality is achieved, then maintained. Like most Lean manufacturing philosophies, TQM builds off of other Lean principles and ideas. TQM was influenced by the teachings of Phillip B. Crosby, Lean forefather W. Edwards Deming, Armand V. Feigenbaum, Kaoru Ishikawa, and Joseph M. Juran.

Lean Manufacturing Objectives

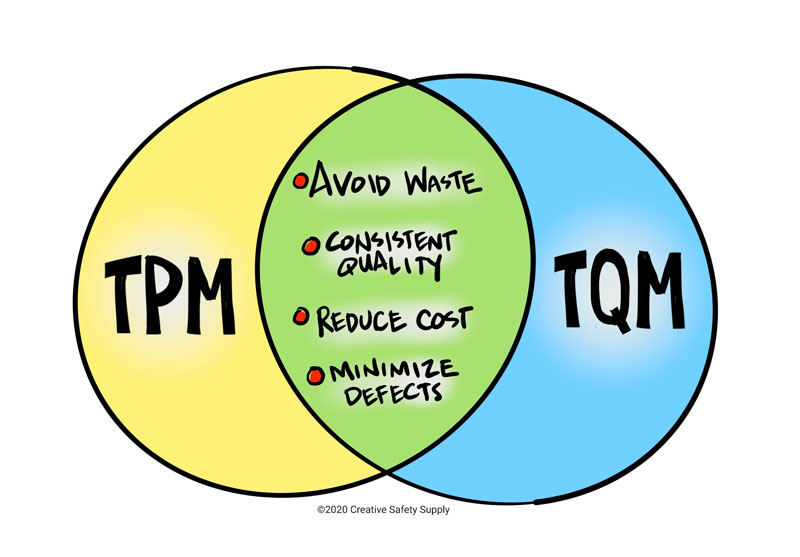

For both TPM and TQM, the goals are the same:

- Avoid waste in fast-paced environments

- Producing quality goods consistently.

- Reduce cost.

- Minimum defects and increase quality.

TPM and TQM are different at their core, but the two programs do closely resemble each other. For instance, both require total commitment and participation from upper level management in order for them to succeed. Employees play a major role in both programs, and both work to empower employees to initiate corrective action.

Similar Questions

- What are the objectives of TPM?

- What does TPM stand for?

- Who developed TPM?

- How can I use visual communication in TPM?

- What are the pillars of TPM?

- How are TPM and Lean related?

- What are the steps to implementing TPM?

- What are some tools of TPM?

- How does TPM relate to OEE?