When planning out a floor marking standard for a facility, it is important by starting with what is required. In many workplaces there will be requirements from OSHA on what type of markings there are, and how they are used. Getting a good understanding of these guidelines will help with planning any type of floor marking strategy while also helping to ensure the company is not found to be in violation of any regulations.

OSHA Color Requirements for Floor Markings

When it comes to floor markings, OSHA is not as strict as it is with many of their other regulations in regards to colors that are used. There are, however, some areas where they do offer guidance in this area. For example, either red or yellow floor markings need to be used when there are physical hazards that are being identified. Red will indicate that the hazard is fire related, and yellow will indicate a hazards that could be tripped over, caught between, or struck against.

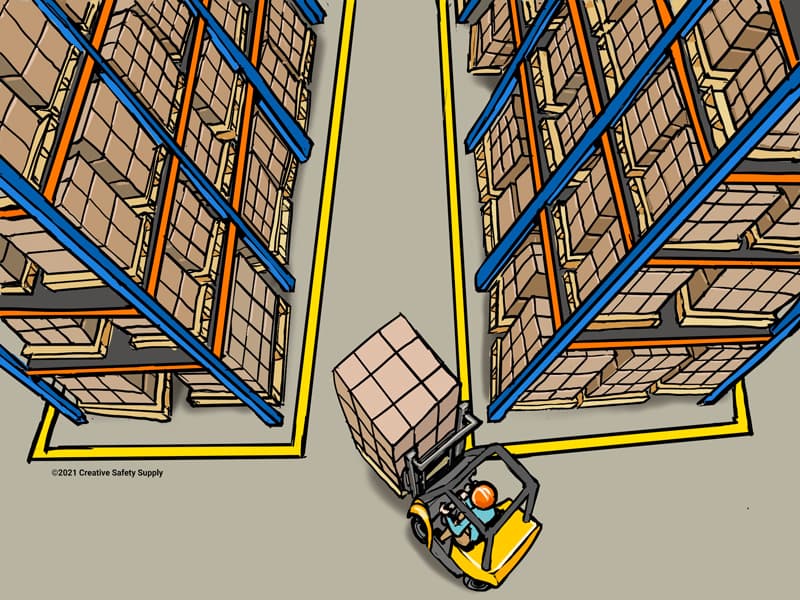

Establishing Aisles and Passageways

OSHA also has some requirements regarding floor markings where there are permanent aisles or passageways in a facility. These are most commonly found in warehouse environments, though they can and do exist in any type of workplace. The regulations say that any of these types of aisleways or passageways must be marked clearly.

They have gone on to further clarify that the markings that are used to identify these areas need to be at least 2’’ wide so they are visible. They recommend the markings are between 2’’ and 6’’ based on the environment and what would maximize visibility. While floor marking tape or paint is the recommended option for this, OSHA has specifically stated that if the floor can’t easily be marked in this way (dirt floors, for example) then a company can use flags, cones, or other markings.

Safety First

There are other floor marking guidelines offered by OSHA, and it is the responsibility of each facility to understand what they need to do in order to remain in compliance. Fortunately, most of the regulations are simply a formalizing of common sense safety concepts. In this case, complying with OSHA will also have a direct benefit to the safety and efficiency of a facility.

Similar Questions

- What are different types of floor marking?

- What are OSHA aisle marking requirements?

- What are floor marking standards?

- What is the difference between floor marking tape and floor paint?

- What are common floor markings in warehouses?

- How can floor markings be utilized in aisles?

- What floor marking can I use for emergency exits and evacuation routes?

- What are floor marking color standards?

- What are common floor markings in factories?