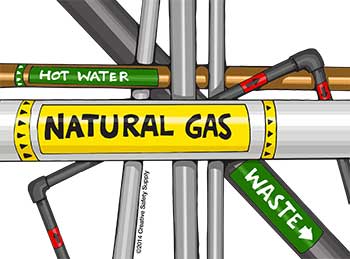

Pipes are often described as the arteries of a facility because they transport various substances from place to place throughout a building. There are dozens, if not hundreds, of different types of liquids, gases, and vapors that can travel through a pipe, and many of them can be quite dangerous. The ability to identify pipe contents with just a glance is very important not only for the efficiency of maintenance employees working on them, but also for the safety of the facility.

Almost all facilities operating in America, and many around the world, follow the ANSI color codes for pipe marking to help ensure everyone is aware of any hazards that might be present within a pipe. While ANSI is not a government agency, and doesn't have any legal authority to enforce their standards, companies choose to follow them because it is well known that these standards improve safety quite significantly.

Pipe Marking Color Code Standards

When following the ANSI A13.1 standard, the most important thing is to understand the six most common color schemes. These colors will be used on almost all pipes to ensure everyone in the facility can immediately recognize the relationship between pipe contents and subsequent hazards that the contents pose. Safety will improve significantly if this simple scheme is applied. The color code standard includes the following.

Not sure which pipe labels you need?

The pipe label calculator helps you choose the right labels for your pipes.

Blue Background with White Text

Any pipe that contains compressed air should be labeled with white text over a blue background. Compressed air is commonly used for cleaning, pressure, and other functions. While it is an important part of many facilities, it can also be quite hazardous. Air at higher pressures can actually puncture skin if someone put his or her hand in front of the nozzle thinking that it was going to be water. This type of blue and white label will minimize that risk.

Green Background with White Text

Pipes containing water not intended for a fire suppression system should be labeled using a green label with white text. This could be water used for drinking, cleaning, a cooling system, etc. As long as it is not being directed into a fire suppression system, this is the right type of label for water.

Brown Background with White Text

Pipes that are labeled with white text on a brown background will contain combustible fluids. People often confuse combustible and flammable since they have a similar meaning. Combustible fluids have a higher flashpoint of over 100 degrees Fahrenheit while flammable fluids are 100 or below. Just because they are not quite as likely to burn, however, does not mean danger is not present. Using this type of label will help ensure people are aware of the risks so they can take proper precautions.

Yellow Background with Black Text

Flammable and oxidizing fluids will need to travel through a pipe labeled with black text on a yellow background. This includes any fluid that could ignite when exposed to heat sources such as flames, sparks, or other igniters, or if the fluid reacts with oxygen (oxidation) and creates rust. A fluid is considered flammable when the flashpoint is at or below 100 degrees Fahrenheit. Having a properly labeled pipe is extremely important for both of these instances because of the high risk these contents pose to employees. Properly labeling these kinds of pipes will also help to alert emergency response teams and assist in rapid resolution of the problem.

Orange Background with Black Text

Toxic and/or corrosive fluids present very serious hazards. These types of fluids, however, can also be used for many different tasks within a facility. To help ensure everyone is as safe as possible, applying a label that has an orange background behind black text is very helpful.

Red Background with White Text

Pipes used to transport fluids for quenching fires should be labeled with white text over a red background. There are many examples of this type of fluid. A common one is fluid that feeds into a fire suppression system. Pipes containing water or other fire suppression fluid that go to sprinklers should have this type of label.

It is important to note that this color scheme is only for fire suppression uses. For example, a pipe containing water that goes to a drinking fountain would NOT have this type of label on it. This is because firemen and other emergency responders need to be able to quickly identify pipes that supply the fire suppression systems.

ANSI Color Codes for User-Defined Labeling

While ANSI has set the above color codes aside for specific purposes, the organization has also reserved several color combinations for user-defined labeling. Each facility can choose what to use these color combinations for. The most important thing to remember when using custom colors is that it should have the same meaning throughout the company.

These labels are intended to improve safety and visual communication, so having everyone in the facility familiar with the meanings of any user-defined labels that are in use is critical. Many facilities won't need to use these options, but for those that do, the choices are:

- Purple Background with White Text

- Gray Background with White Text

- Black Background with White Text

- White Background with Black Text

What Goes on the Pipe Labels?

In addition to having the right colors on those pipes, it is also important to have the right text and symbols on the labels. Most facilities tend to keep pipe label contents fairly basic. Attempting to use an excessive amount of wording will make it impossible to read from any distance, which makes it essentially useless.

Adding arrows to indicate flow direction is very helpful. Large words like "WARNING" or "FLAMMABLE" can also be used in these situations. Evaluating how to convey the needed message quickly and clearly to people in the area will help ensure the pipe labels improve safety as much as possible.

Making Sure Pipe Markings Are Visible

In addition to following the ANSI color code standards, a facility also needs to make every effort to ensure the labels are visible. Since pipes can be located anywhere in the facility from under the floor to high up in the rafters, proper placement of the labels is very important.

The standard rule of thumb is to make sure the text is positioned in such a way that it will be immediately visible to people looking at it from the most likely direction. Pipes that travel up through the rafters should have the labels positioned so the text is at an angle pointing down toward the ground. This way people on the floor can read them, as well as people who are up on a rafter working on the pipes themselves.

Other strategies that can be used to increase the visibility of pipe markings, include the following:

- Multiple Labels - Using labels every 50 or less will make sure people can follow the pipe along and always be aware of its contents.

- Near Obstructions - When the pipe has a valve, flange, or other obstruction to visibility, a label should be applied on either side.

- Through Walls - Pipes often travel through walls. When this is the case, a pipe label should be applied to the pipe on either side of the wall to increase visibility.

Perhaps most important is that anyone using pipe markings should also apply common sense. If there are certain areas illuminated by lights and others that are dark, putting the labels in the light just makes sense. Rather than just slapping a label on every set amount of distance, the team working on this project should take the time to really think about the visibility of the labels and how it will be seen from different areas within the facility.

Custom Printing of ANSI Compliant Pipe Markings

When attempting to begin the process of labeling pipes according to the ANSI color codes, facilities will need to decide where their pipe labels will come from. There are two main options available. Some companies choose to buy the labels they need pre-printed, and others choose to print the labels themselves with an industrial label printer.

While both can be effective, having an industrial label printer onsite in the facility comes with many additional benefits. In addition, on a price per label basis, it will actually be less expensive to have them printed in the facility rather than ordering them from another company. Of course, there is a somewhat higher up-front cost if the facility doesn't already have a good quality label printer.

Once a facility reaches a certain size, the only real option is to print custom labels right on site. This will make it possible to ensure new labels can be made whenever the old ones begin to wear out, are damaged, or when new pipes are being installed. The printer can also be used in many other areas of the facility, which makes its return on investment even greater.

Resources

- http://www.differencebetween.net/science/difference-between-flammable-and-combustible/

- https://ansi.org/

Similar Articles

- Pipe Color Codes – ANSI/ASME A13.1

- Safety Colors (OSHA Guidelines and Color Codes)

- A Guide to Pipe Marking Standards

- Electrical Wiring (Wire Color Codes)

- Pipeline Labeling

- Your Guide to Pipe Labeling Standards

- Types of Floor Marking

- ANSI TIA 606-B Cable Labeling Standards

- Valve Tags: Guide for Pipe Identification