Electricity, as a primary source of power to many, can still pose an enormous risk to those who handle it without the proper knowledge or tools within arm’s reach. A trade off of possible danger for utility and functionality is present all around us within the industrial world. Which is why holding safety, especially pertaining to electricity, should be a high priority across the board.

Working to improve workplace electrical safety is part of OSHA and the NFPA’s priorities. However, they are the givers of information. In reality, those who work in close proximity to this type of hazard are fully responsible for using that information to protect themselves from danger.

Electrical Safety in the Workplace

Electrical safety is multi-faceted, there is no one solution that instantly saves employees and others from encountering all hazardous situations and potentially suffering severe injuries or death. In fact, building a safe workplace takes quite a few steps at the minimum. The following list is the bare minimum that each facility must work towards and keep track of regarding electrical safety.

- Know the regulations and requirements – Knowing what OSHA and the NFPA have to say about electrical work is incredibly important for determining what the individual facility needs.

- Identify all the present hazards – Try implementing a weekly or monthly Gemba walk to talk to employees about any problems they’ve noticed around the facility.

- Learn the best practice methods – There is always a better way to do things, and when it comes to electrical safety the NFPA is an expert resource to use.

- Go through the auditing process regularly – Create a checklist and perform a safety audit once a year, every year to ensure everything is in tip-top shape. The company is then able to gather any improvement recommendations.

- Have the right PPE on hand – PPE is essential for employees whenever they set out to complete tasks involving electrical components. The employer must do their due diligence when it comes to picking out the correct PPE for the appropriate hazard category pertaining to arc flashes and other electrical hazards.

- Develop an electrical safety program – Providing employees with a plan of action and detailed training is always a part of any electrical safety program. This keeps everyone informed.

- Use visual communication – Use reminders in the form of visual communicators. These are often inexpensive tools that can save the company hundreds if not thousands of dollars in damage due to accidents.

- Train employees on both arc flash protocol and standard electrical tasks – Training is one of the best things to give to employees as it enables them to protect themselves from danger.

What is an Electrical Hazard in the Workplace?

Electrical hazards come in many shapes and sizes. Some of the most common recognizable electrical hazards include the following:

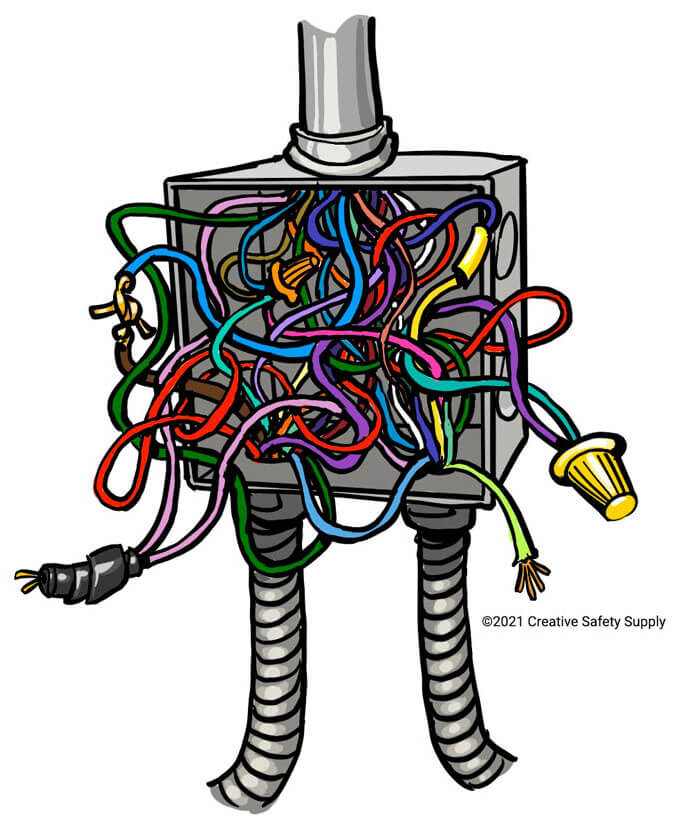

- Exposed/faulty wiring

- Improper/lack of grounding practices

- Overloaded circuits

- Damp conditions

- Down powerlines

These are only some examples of electrical hazards that can appear in any workplace. All of which can result in fires or possibly deadly electrical shocks and electrocutions, and most of them are tied to neglect in inspections or lack thereof.

OSHA + Electrical Safety Standards

There are a handful of electrical regulations that OSHA specifies in its General Industry section of 29 CFR 1910. These include:

- 1910.137 Electrical Protective Equipment

- 1910.269 Electric Power Generation, Transmission, and Distribution

- 1910 Subpart S – Electrical

There are also electrical requirements pertaining to maritime operations:

- 1915.181 Electrical Circuits and Distribution Boards

- 1917.157 Battery charging and Changing

It is the employer’s job to know the standards applicable to their specific environment, this way they will be able to give their employees the correct training, PPE, and other necessary safety measures that keep everyone as safe as possible.

Does OSHA Require a Written Electrical Safety Program?

The short answer is yes, OSHA does indeed require a written electrical safety program.

To be more specific, OSHA directly states in Subpart S, 1910.304(b)(3)(ii)(C)(1) “A written description of the program, including the specific procedures adopted by the employer, shall be available at the jobsite for inspection and copying by the Assistant Secretary of Labor and any affected employee.” This is directly referring to OSHA’s requirements on wiring design and protection. OSHA also references another instance in 1910.333(b)(2)(i), also in Subpart S, where a written plan is required for the company’s process on lockout tagout procedures.

OSHA only requires written procedures when they deem the related hazards dangerous enough to warrant one, which means the repercussions of neglecting to provide one are severe. Following this rule is essential for clear complete mutual understanding between all employees, employers, and the dangers they face every day at work.

What is NFPA 70E?

The NFPA published the Standard for Electrical Safety in the Workplace, more commonly recognized as NFPA 70E, in an attempt to address best practice methods for electrical safety that also help improve workplace productivity. It is often misinterpreted as the same thing as NFPA 70, also known as NEC which instead contains a broader scope of information about electrical hazards and protection measures.

The NFPA 70E standard goes over several related topics such as installed electrical conductors and the connection to an electricity supply while also outlining the following:

- Shock protection boundaries

- Arc flash incident energy

- Lockout tagout

- Electrical PPE

However, remember that the NFPA addresses best practice methods that other regulation bodies like OSHA endorse. It is always a good idea to follow best practice methods because they have been proven to improve safety efforts even though they aren’t necessarily required.

Floor Marking for Electrical Panels

Before figuring out what exactly is needed for floor marking around electrical panels, refer to OSHA’s section 1910.303 to confirm the appropriate clearance for electrical equipment. This will be dependent on the voltage that the particular panel has, it is usually three feet, but that can change.

Once the appropriate distance has been determined for these electrical hazards, then the colors and the signs can be chosen. Employers often go with a simple “Do Not Block Electrical Panel” sign for the floor because they are simple and eye catching. However, the addition of black and yellow hazard floor tape is also recommended to enforce that 36 inches or more distance between the machine and employees.

The simple addition of visual communication such as this works to prevent electrocution, arc flashes, and other electrical circuit problems. It also works to remind employees that they may need PPE to enter that area. Regardless, extra communication about these kinds of hazards is always a welcome sight.

Electrical Safety Sign Requirements

Looking for specific guidelines of electrical safety signs can be difficult, but if the right resources are found, creating OSHA compliant safety signs is easy.

First take a look at the general rules put forth by OSHA in section 1910.145 “specification for accident prevention signs and tags.” This standard explains the general sign design and the appropriate signal words to use depending on the level of danger present.

Electrical safety sign requirements can also be seen within the National Electric Code created by the NFPA. Section 110.16(B) specifically deals with label design, where they are placed, the durability of the material, and other equipment specific information.

Standards for Arc Flash Labels

The NFPA 70E goes over the requirements for arc flash labels. Every label must include the following elements:

- The nominal system voltage

- The date of the last arc flash risk assessment performed

- The arc flash boundary

- Arc flash PPE category or the incident energy level and appropriate working distance

- The minimum rating for arc clothing

- The description of PPE required per site specifications

Safeguarding Workers

The is the last and probably one of the most important aspects of providing a workplace free of hazards. Safeguarding workers from electrical hazards is primarily done with three objectives:

- Providing appropriate training and equipment

- Creating a visual workplace with labels and electrical safety signs

- Creating an electrical safety program

Each of these aspects regarding electrical safety all work together to prevent accidents during working hours. The employer has all the necessary tools to equip their employees, both material and knowledge, for them to protect themselves from dangers they face every day.

Similar Articles

- Floor Marking for Electrical Panel Compliance

- Arc Flash and Electrical Safety

- 10 Essential Steps for Electrical Safety

- Fire Safety in the Workplace

- Electrical Wire Colors

- Addressing Biohazard Safety in the Workplace

- Electrical Wiring (Wire Color Codes)

- Workplace Safety Inspections & Audits

- Creating a Visual Workplace